Sodium alginate-hydroxyapatite hybridization nano particle and preparing method thereof

A technology of hybrid nanoparticles and hydroxyapatite is applied in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., and can solve the problems of affecting the therapeutic effect and inaccessibility of drug carriers, etc. Achieve the effect of increasing specific surface area, good drug treatment effect, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

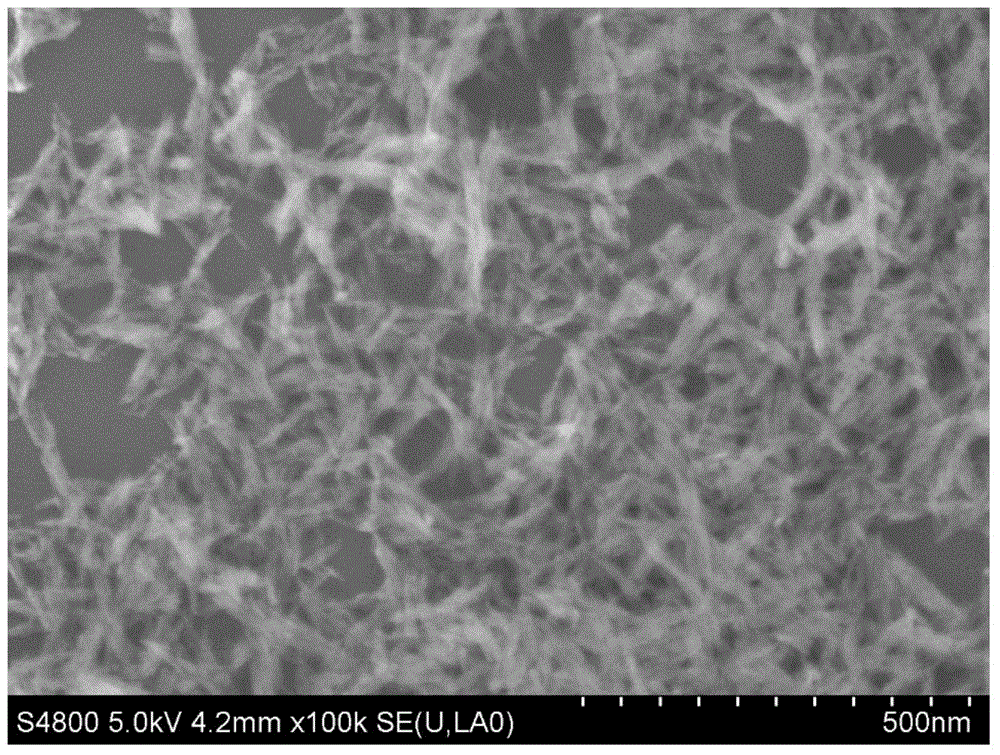

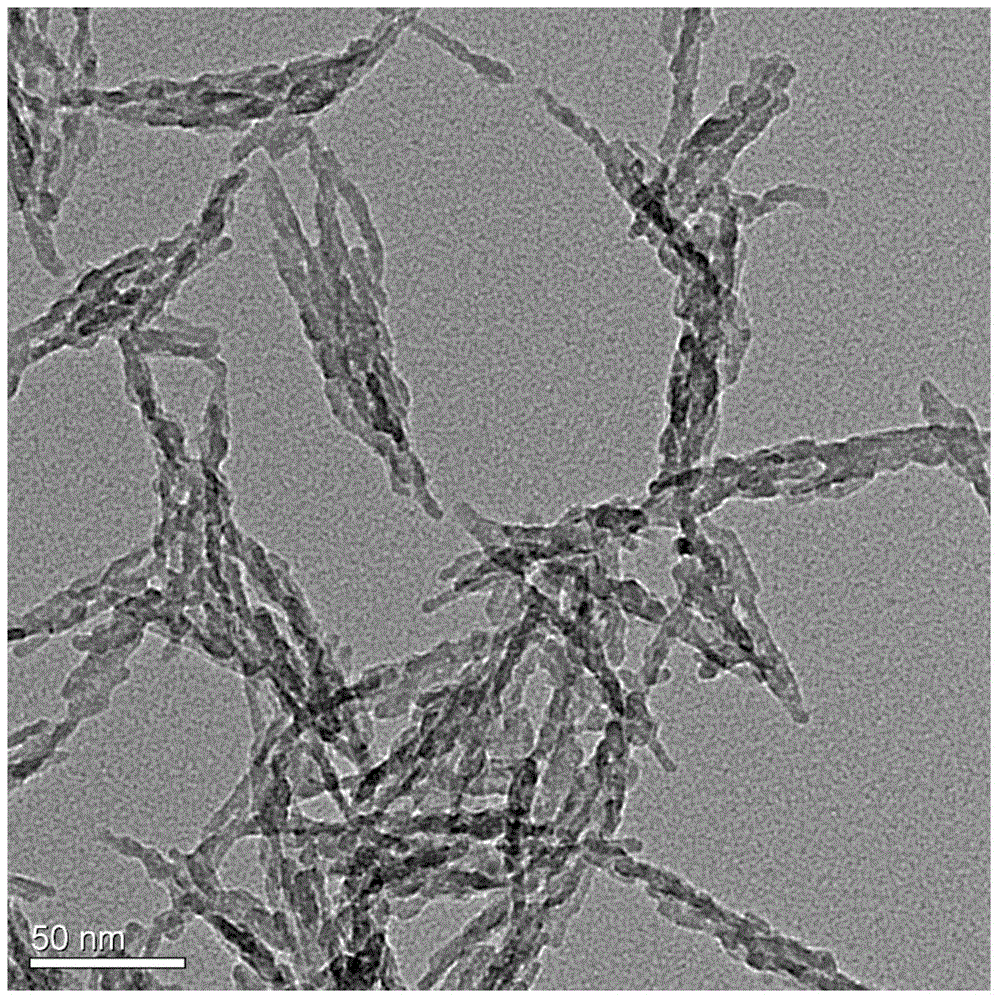

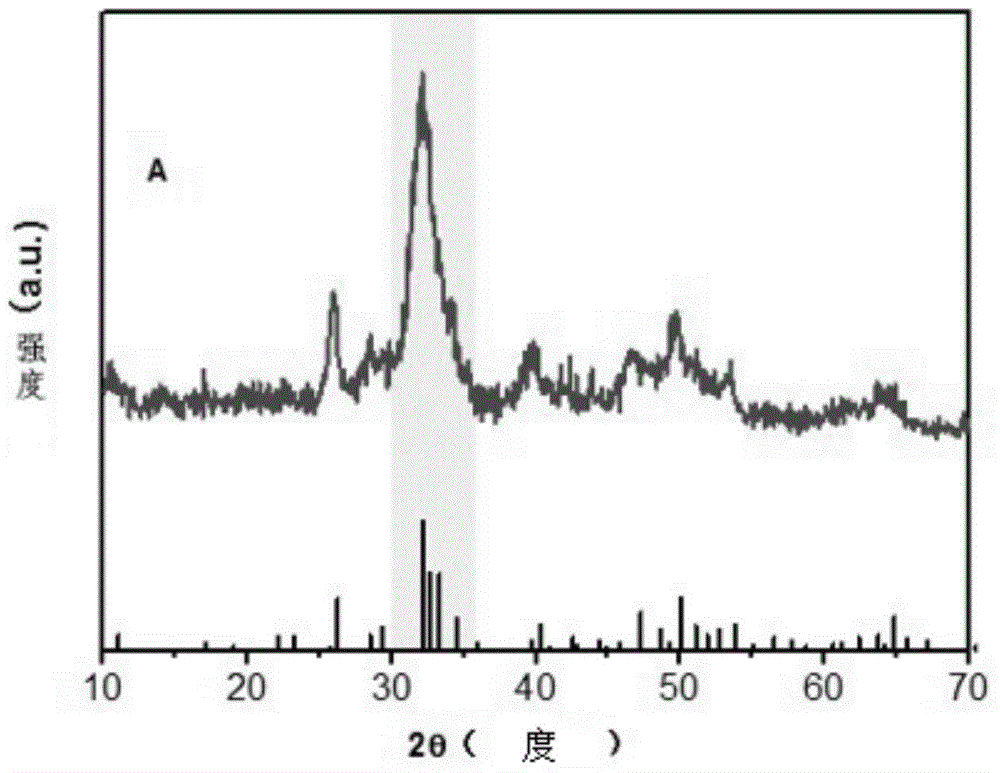

[0030] Add 0.32 kg of sodium alginate with a molecular weight of 120 KDa to deionized water at room temperature to prepare 40 L of sodium alginate solution. Add CaCl with a concentration of 0.01 mol / L to the resulting sodium alginate solution at a stirring speed of 400 rpm 2 4H 2 O aqueous solution and Na at a concentration of 0.01 mol / L 2 HPO 4 12H 2Each 1 L of O aqueous solution, followed by NaOH aqueous solution with a concentration of 0.1 mol / L and hydrochloric acid with a concentration of 0.1 mol / L was used to adjust the pH value of the reaction system. When the pH value was stabilized at 11, the stirring was stopped and left to age for 7 days. After standing and aging, the precipitate was collected by centrifugation at a speed of 5000 rpm, washed with deionized water for 3 times, and then the washed precipitate was placed in a freeze dryer and freeze-dried at -20°C (Negative pressure: 0.1Mpa) After 52 hours, sodium alginate-hydroxyapatite hybrid nanoparticles were ob...

Embodiment 2

[0036] Add 0.16 kg of sodium alginate with a molecular weight of 150 KDa to deionized water at room temperature to prepare 40 L of sodium alginate solution. Add CaCl with a concentration of 0.4 mol / L to the resulting sodium alginate solution at a stirring speed of 400 rpm 2 4H 2 O aqueous solution and concentration of 0.2mol / L (NH 4 ) 2 HPO 4 2H 2 Each 1 L of O aqueous solution, followed by NaOH aqueous solution with a concentration of 0.1 mol / L and hydrochloric acid with a concentration of 0.1 mol / L is used to adjust the pH value of the reaction system to be stable at 11, stop stirring, and leave to age for 7 days. After standing and aging, the precipitate was collected by centrifugation at a speed of 5000 rpm, washed with deionized water for 4 times, and then the washed precipitate was placed in a freeze dryer and freeze-dried at -40°C (with a negative pressure of 0.1Mpa) for 48 hours, sodium alginate-hydroxyapatite hybrid nanoparticles were obtained.

[0037] The test...

Embodiment 3

[0039] Add 0.08 kg of sodium alginate with a molecular weight of 150 KDa to deionized water at room temperature to prepare 40 L of sodium alginate solution. Add CaCl with a concentration of 0.6 mol / L to the resulting sodium alginate solution at a stirring speed of 400 rpm 2 4H 2 O aqueous solution and NaH with a concentration of 0.6mol / L 2 PO 4 2H 2 Each 1 L of O aqueous solution, followed by NaOH aqueous solution with a concentration of 0.1 mol / L and hydrochloric acid with a concentration of 0.1 mol / L is used to adjust the pH value of the reaction system to be stable at 11, stop stirring, and leave to age for 7 days. After standing and aging, the precipitate was collected by centrifugation at a speed of 5000 rpm, washed with deionized water for 4 times, and then the washed precipitate was placed in a freeze dryer and freeze-dried at -40°C (with a negative pressure of 0.1Mpa) for 48 hours, sodium alginate-hydroxyapatite hybrid nanoparticles were obtained.

[0040] The tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com