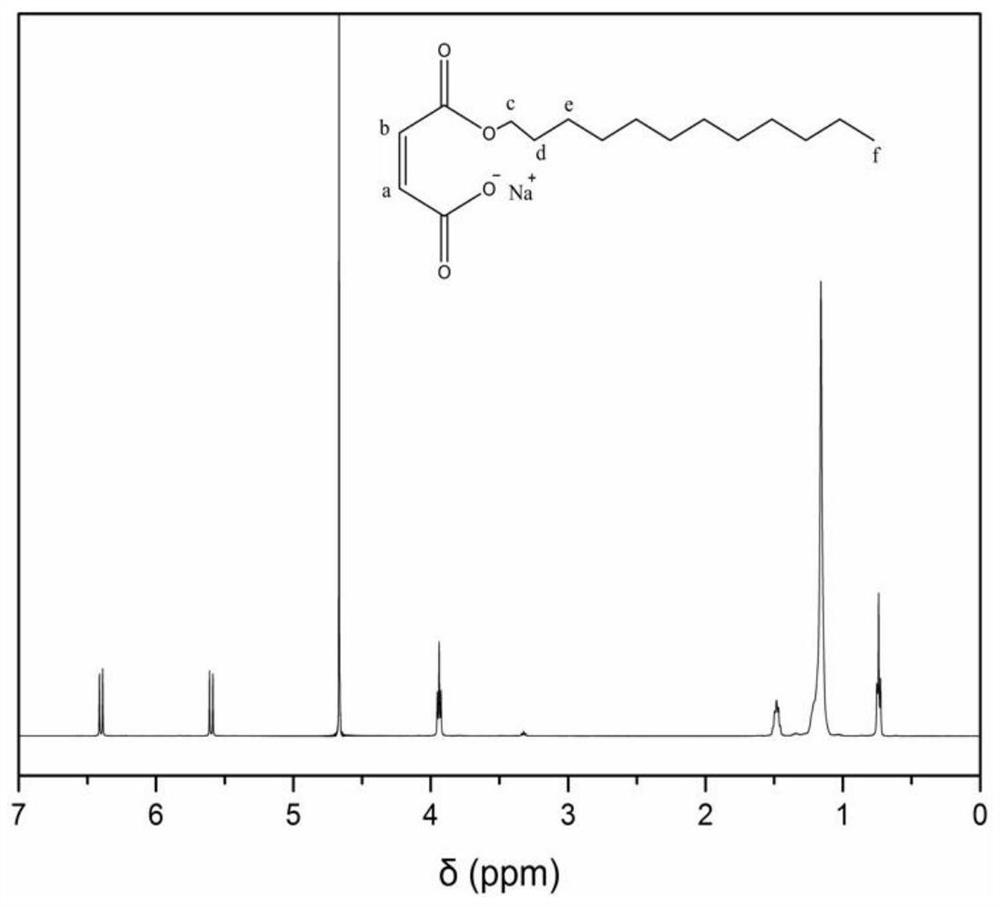

Polystyrene-maleic acid fatty alcohol ester sodium salt-aluminum trioxide nanocomposite material and preparation method thereof

A technology of nanocomposite materials and aluminum oxide, which is applied in the field of polystyrene-fatty alcohol maleate sodium salt-aluminum oxide nanocomposite materials and its preparation, can solve the problem of strong surface interaction, cumbersome steps, polymerization Solve the problems of inconvenient preparation of material-based nanocomposites, achieve a uniform and stable dispersion state, and solve the effect of serious agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

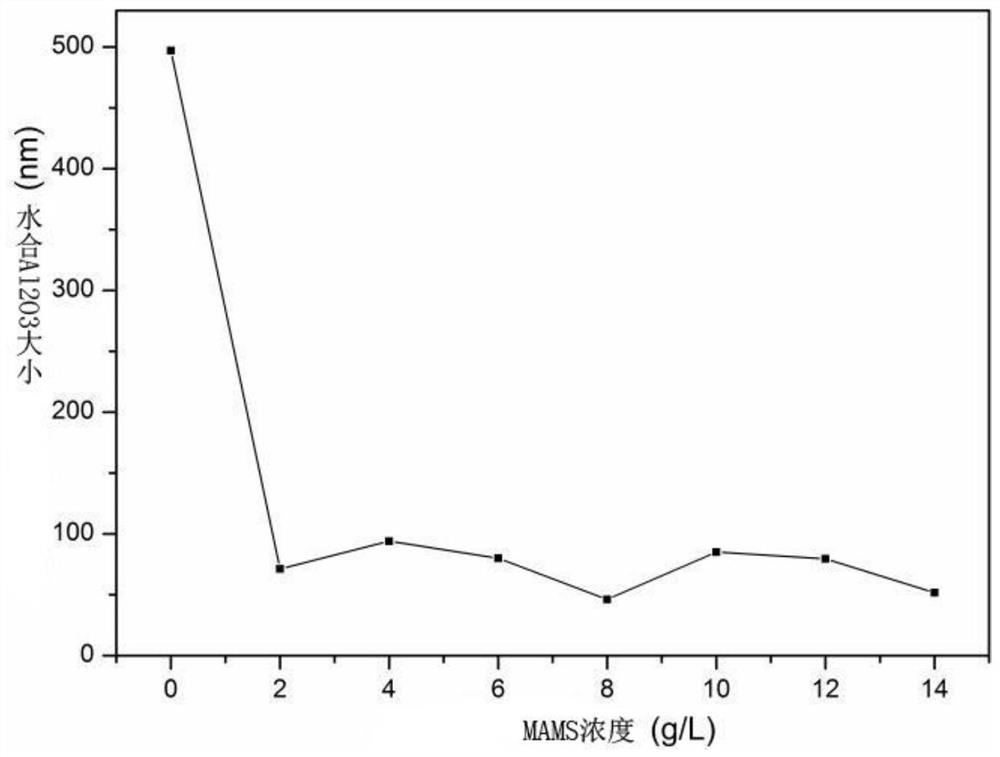

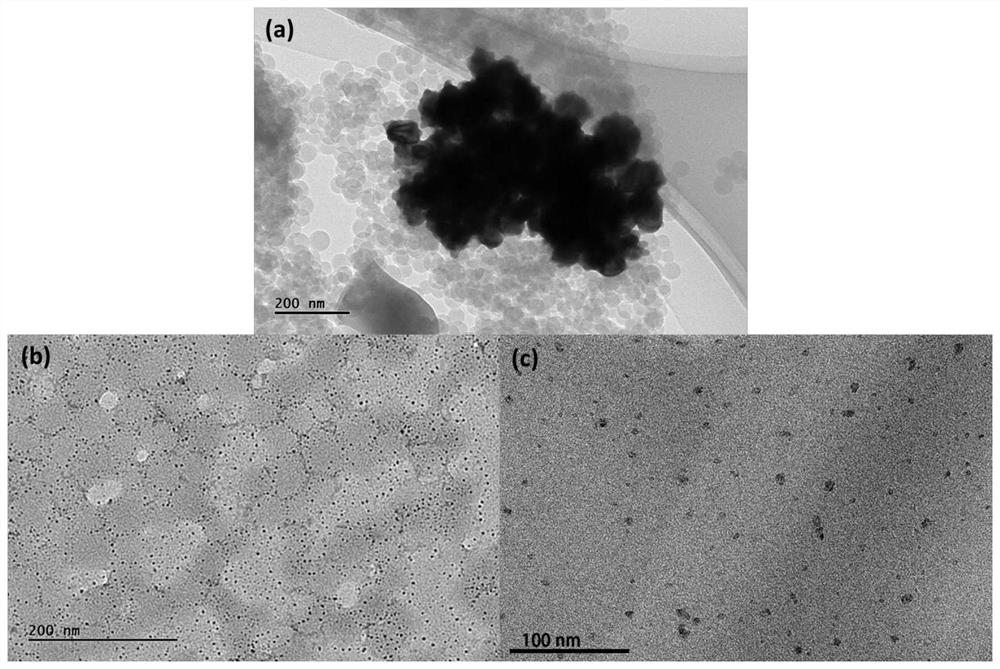

[0043](1) Preparation of polystyrene-aluminum oxide nanocomposite emulsion with anionic monomer MAMS as emulsifier: weigh 0.5g MAMS, 0.057g initiator KPS, dissolve in 50mL deionized water, and weigh 10g monomer Styrene was added to a 250mL four-necked flask, stirred at 700rpm for 2h to pre-emulsify, and then added the pre-emulsion to the constant pressure dropping funnel for later use;

[0044](2) Add 0.5g Al2O3Nanoparticles and 0.5g anionic monomer MAMS were dispersed in 50mL deionized water, and ultrasonically dispersed with JY92-II N-type ultrasonic cell pulverizer. The setting parameters were: power 600W, working time 3s, intermittent time 2s, ultrasonic in ice bath environment 30min, add the ultrasonic dispersion into a 250mL four-necked flask; then weigh 10g of styrene and add it to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set the stirring speed to 700rpm, and start to heat up after 0.5h; When it reaches 70℃, weigh out 0.057g KPS, diss...

Embodiment 2

[0048](1) Preparation of polystyrene-aluminum oxide nanocomposite emulsion with anionic monomer MAMS as emulsifier: weigh 0.4g MAMS, 0.057g initiator ABIN, dissolve in 50mL deionized water, and weigh 10g monomer Styrene, added to a 250mL four-necked flask, stirred at 700rpm for 2h to pre-emulsify, add the pre-emulsion to the constant pressure dropping funnel for later use;

[0049](2) Add 0.5g Al2O3Nanoparticles and 0.6g anionic monomer MAMS were dispersed in 50mL deionized water, and ultrasonically dispersed with JY92-II N-type ultrasonic cell pulverizer. The setting parameters were: power 600W, working time 3s, intermittent time 2s, ultrasonic in ice bath environment 30min, add the ultrasonic dispersion into a 250mL four-necked flask; then weigh 10g of styrene and add it to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set the stirring speed to 700rpm, and start to heat up after 0.5h; When it reaches 70℃, weigh out 0.057g of initiator ABIN, dis...

Embodiment 3

[0053](1) Preparation of polystyrene-alumina nanocomposite emulsion with anionic monomer MAMS as emulsifier: Weigh 0.6g MAMS, 0.057g initiator ABVN, dissolve in 50mL deionized water, and weigh 10g monomer Styrene was added to a 250mL four-necked flask, stirred at 700rpm for 2h to pre-emulsify, and then added the pre-emulsion to the constant pressure dropping funnel for later use;

[0054](2) Add 0.5g Al2O3Nanoparticles and 0.4g anionic monomer MAMS were dispersed in 50mL deionized water, and ultrasonically dispersed by JY92-II N-type ultrasonic cell pulverizer. The setting parameters were: power 600W, working time 3s, intermittent time 2s, ultrasonic under ice bath environment 30min, add the ultrasonic dispersion into a 250mL four-necked flask; then weigh 10g of styrene and add it to a 250mL four-necked flask, pre-emulsify in a water bath at room temperature for 0.5h, set the stirring speed to 700rpm, and start to heat up after 0.5h; When it reaches 70℃, weigh out 0.057g of initiator A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com