Alpha-calcium sulfate hemihydrate/hydroxyapatite composite granule with nuclear shell structure and preparation thereof

A technology of hydroxyapatite and calcium sulfate hemihydrate, which is applied in medical science, prosthesis and other directions, can solve problems such as not being well controlled, and achieve the effects of good clinical application prospect, simple and easy preparation method and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get the deionized water of 40ml as solvent, add the sodium citrate of 0.02g and the magnesium sulfate that massfraction is 0.8g, stir until dissolving completely, make crystallization solution; Add 10g calcium sulfate dihydrate powder (analytically pure grade ), and then add 7.5g of hydroxyapatite to form a solid-liquid mixed system.

[0028] The prepared solid-liquid mixed system was placed in a hydrothermal kettle at 130°C for constant temperature treatment for 6 hours. After the hydrothermal treatment, the gas was released, and the hydrothermal kettle was quickly taken out, and the crude product was filtered out from the hydrothermal kettle. After being filtered and washed with water, it was dried in an oven at 90°C to obtain the final product in the form of granules.

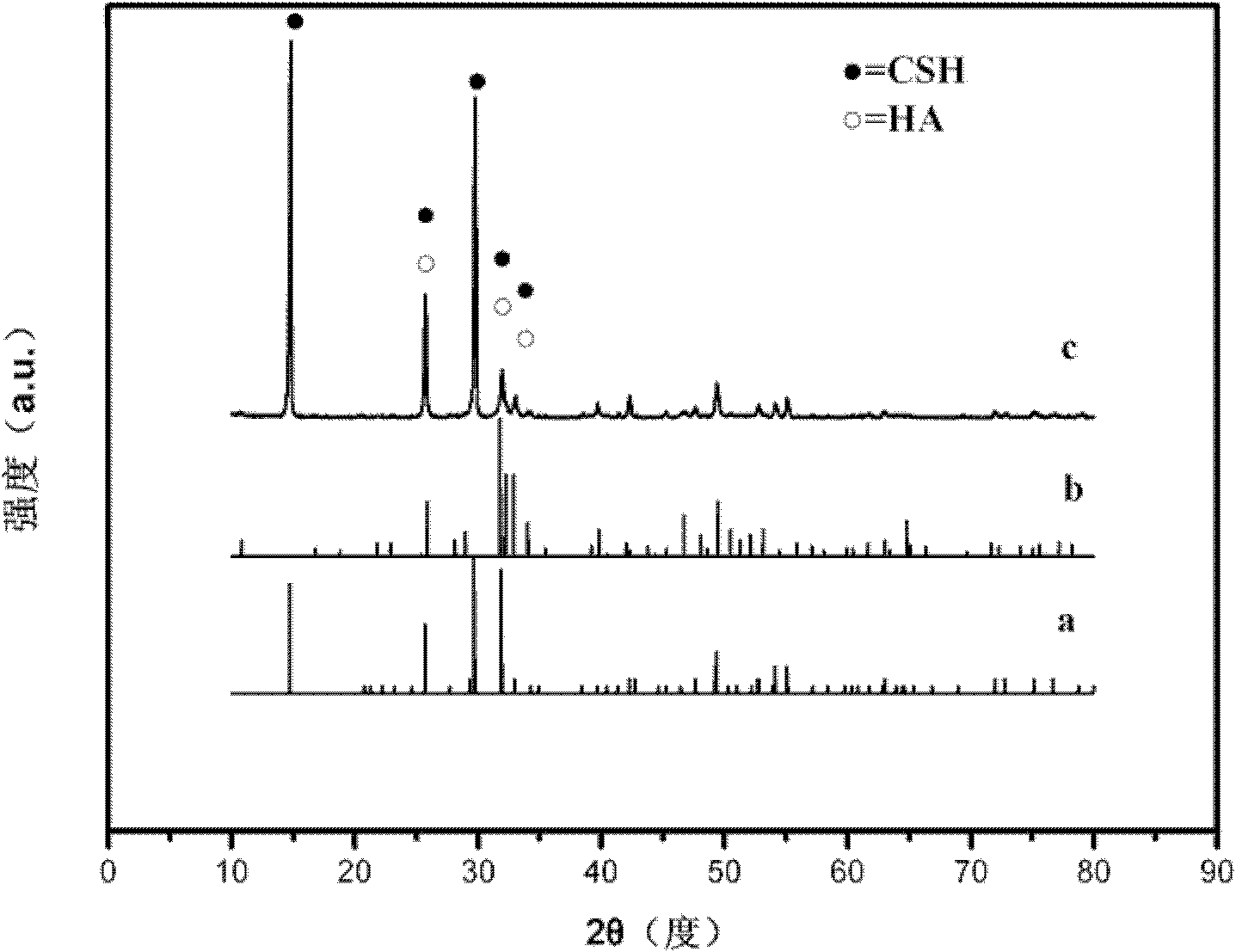

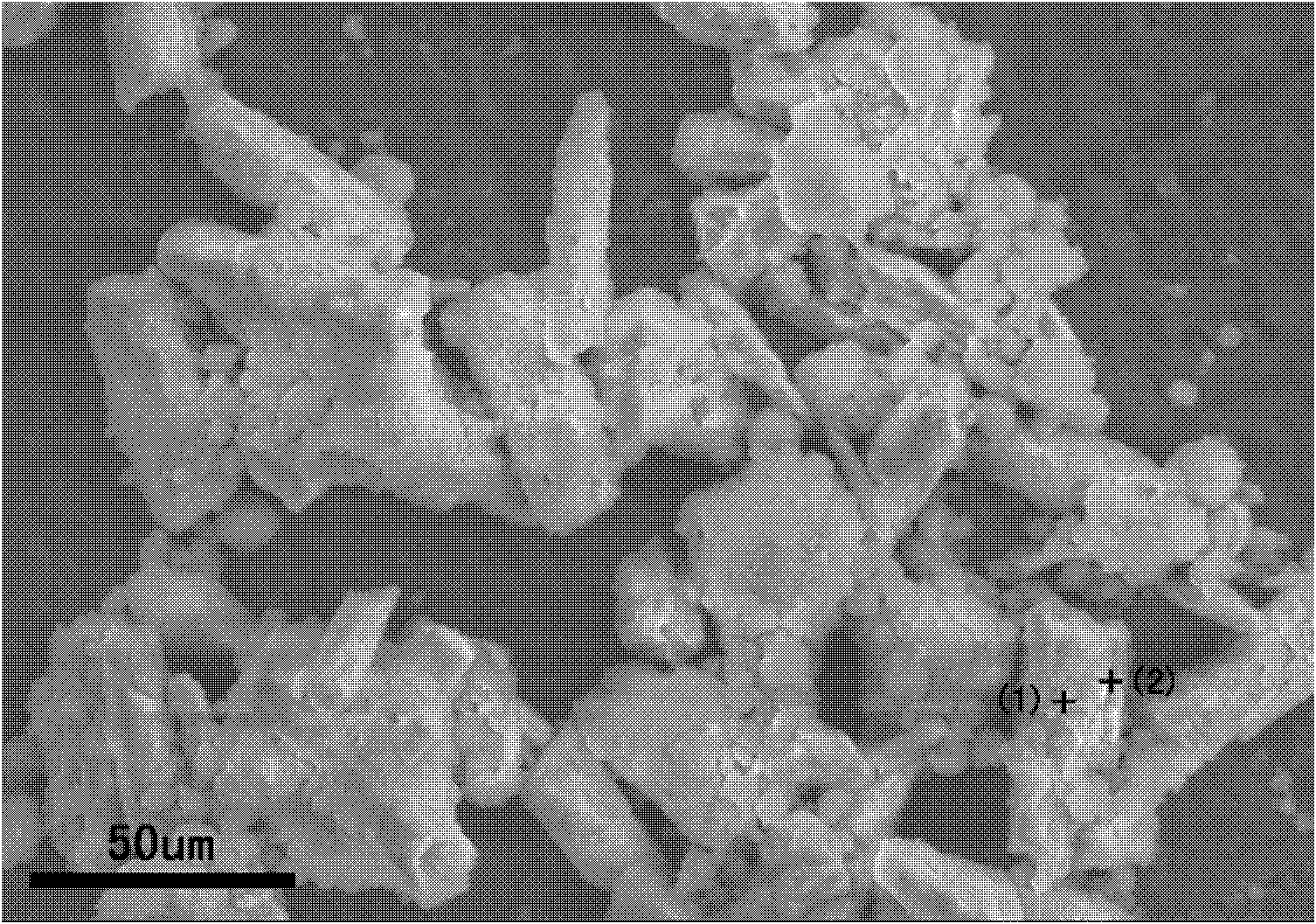

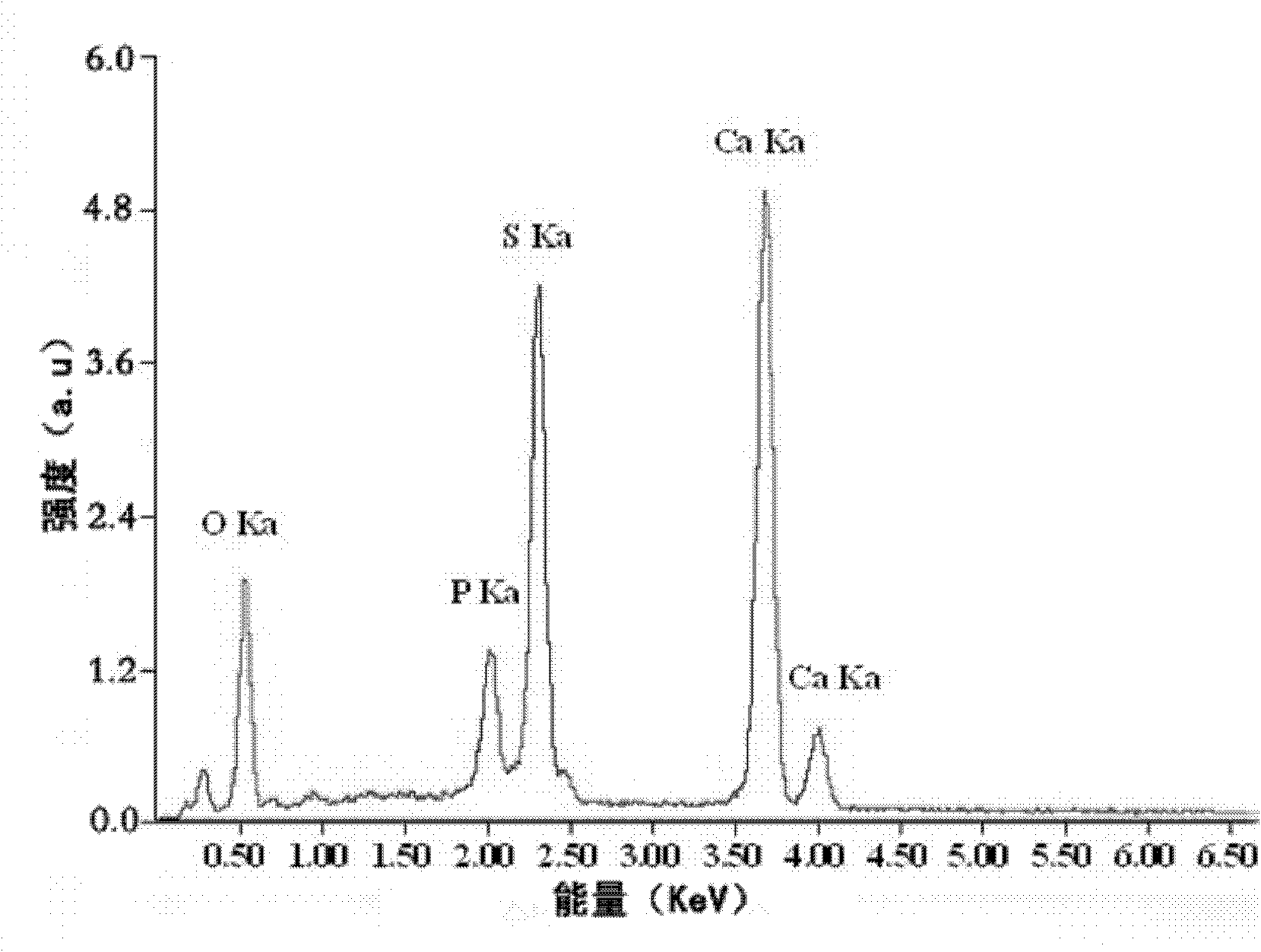

[0029] Adopt X-ray diffractometer to carry out component analysis and component characterization to the final product of gained, XRD collection of illustrative plates is as follows figure 1 shown. f...

Embodiment 2

[0033] Get the deionized water of 40ml as solvent, add the succinic acid of 0.04g and the aluminum sulfate of 0.6g, stir until dissolving completely, make the transcrystal solution; Add 10g calcium sulfate dihydrate powder (analytically pure grade) wherein, add 5g of hydroxyapatite forms a solid-liquid mixed system.

[0034] The prepared solid-liquid mixed system was placed in a hydrothermal kettle at 160°C for constant temperature treatment for 4 hours. After the hydrothermal treatment, the gas was released, and the hydrothermal kettle was quickly taken out, and the crude product was filtered out from the hydrothermal kettle. After being filtered and washed with water, it was dried in an oven at 110° C. to obtain the final product in the form of granules.

[0035] Adopt X-ray diffractometer to carry out component analysis and component characterization to the final product of gained, XRD collection of illustrative plates is as follows Figure 5 shown. Figure 5 Among them, ...

Embodiment 3

[0038] Get the deionized water of 40ml as solvent, add the citric acid of 0.08g and the magnesium sulfate of 0.2g, stir until dissolving completely, make crystallization solution; 2.5g of hydroxyapatite forms a solid-liquid mixed system.

[0039] The prepared solid-liquid mixed system was placed in a hydrothermal kettle at 140°C for constant temperature treatment for 8 hours. After the hydrothermal treatment, the gas was released, and the hydrothermal kettle was quickly taken out, and the crude product was filtered out from the hydrothermal kettle. After being filtered and washed with water, it was dried in an oven at 90°C to obtain the final product in the form of granules. After characterization, the final product is α-calcium sulfate hemihydrate / hydroxyapatite composite particles with core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com