Bacteria cellulose/gelatin/hydroxyapatite composite material and preparation method thereof

A technology of bacterial cellulose and hydroxyapatite, which is used in medical science, prosthesis and other directions, can solve problems such as poor mechanical properties, and achieve the effects of low cost, simple process, and favorable growth and reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

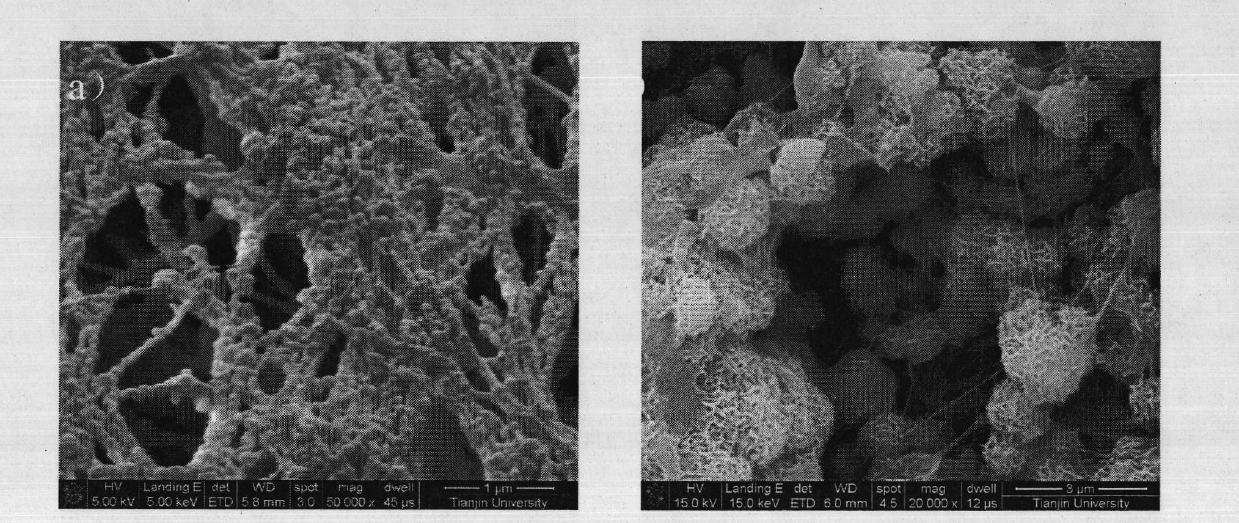

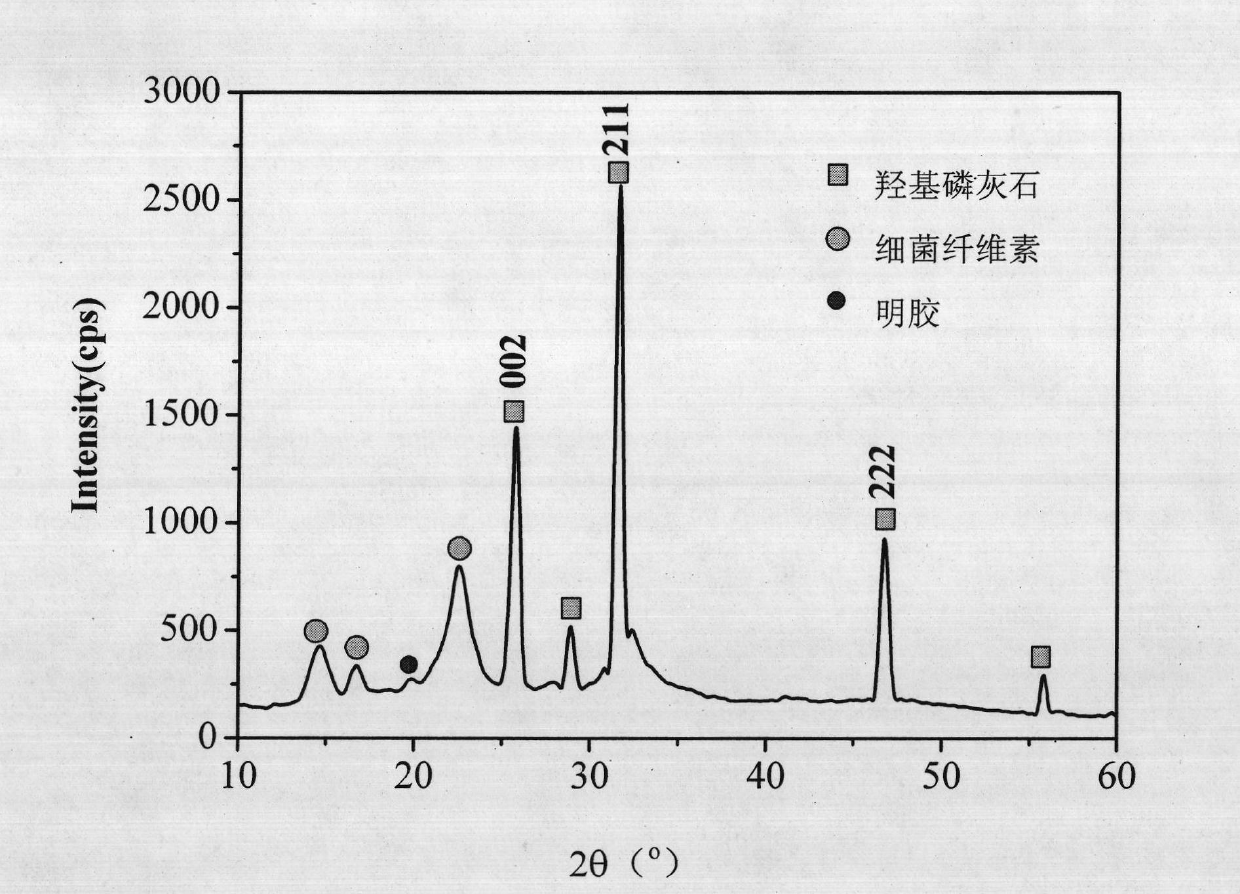

Image

Examples

Embodiment 1

[0019] Add glucose, peptone, yeast powder, and disodium hydrogen phosphate to the beaker in sequence according to the mass fraction of 2.5%, 1%, 0.75%, and 1%, respectively, adjust the pH value to 4.5 with acetic acid, and take it out after half an hour of high-temperature sterilization at 115 degrees Celsius , as a growth medium for Acetobacter xylinum.

[0020] Acetobacter xylinum strains were stored in agar solid medium at 4°C. Use an iron wire to scratch lightly in the solid medium, immediately immerse in 100 ml of liquid medium, shake and cultivate at 30 degrees Celsius for 30 hours, and the shaker speed is 160 rpm, as a seed solution. Inoculate the liquid culture medium with an inoculum volume fraction of not less than 6% of the seed solution, oscillate sufficiently to make the bacterial liquid uniform, and culture at a constant temperature of 30 degrees Celsius for 5 days to obtain a bacterial cellulose gel film. Wash with 1% sodium hydroxide solution until milky white...

Embodiment 2

[0026]100 ml of 1 g / L gelatin aqueous solution was prepared, and the gel film was soaked in a pre-prepared simulated body fluid at a constant temperature for 3 days. Other experimental conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com