Method for preparing bioactive poly(lactic-co-glycolic acid)/collagen/hydroxyapatite composite fiber membrane for bone repair

A technology of composite fiber membrane and hydroxyapatite, which is applied in medical science, prosthesis, etc., can solve the problems of poor mechanical properties and achieve the effects of excellent comprehensive performance, good biocompatibility, and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

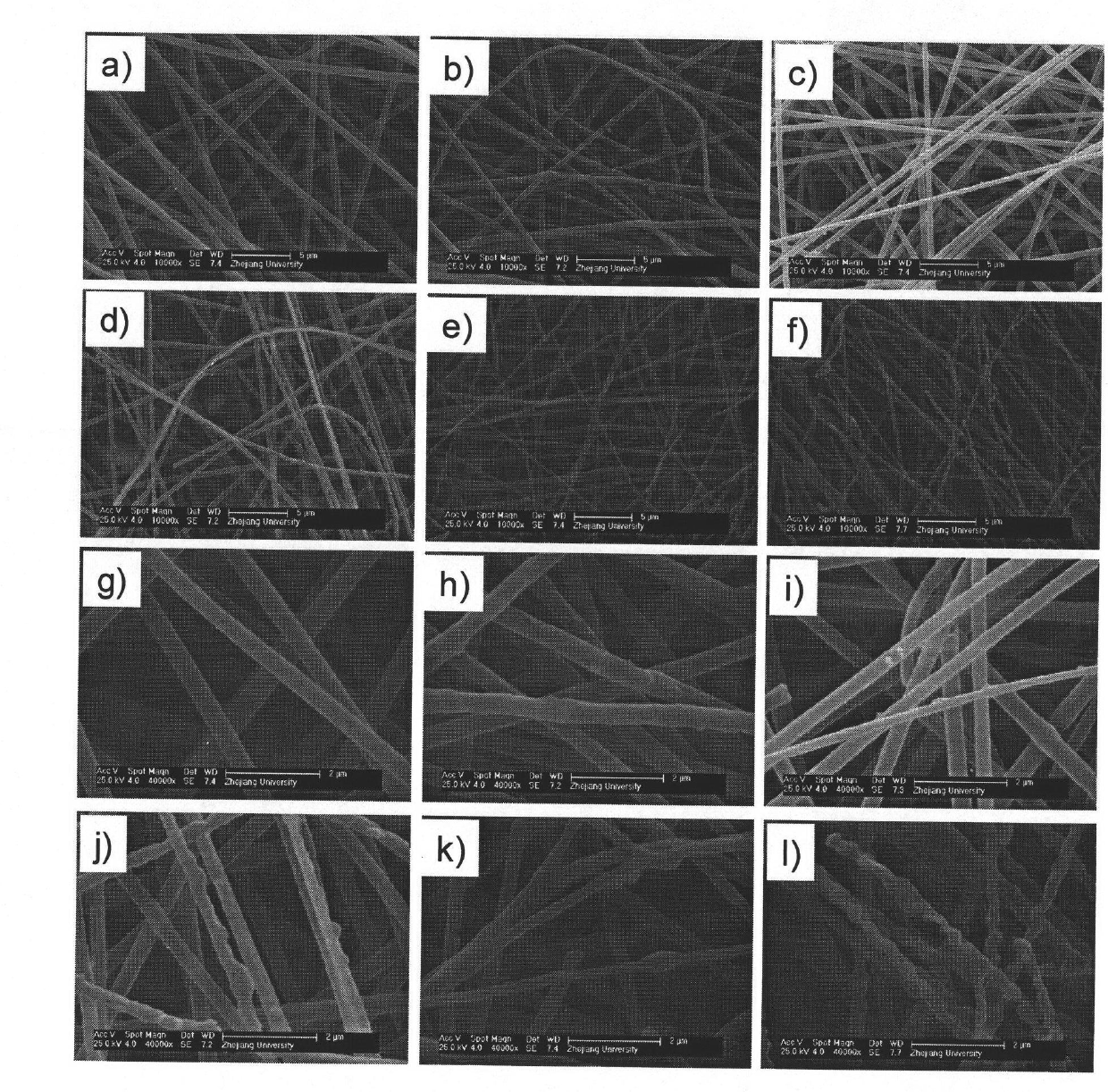

[0035] 1) Dissolve 1.5g of poly(lactic acid-glycolic acid) in 10mL of tetrahydrofuran / dimethylformamide mixed solvent with a volume ratio of 1 / 1, that is, the mass concentration is 15%, and the solution is added to a 20mL syringe Perform electrospinning, set the flow rate to 1.0mL / h, the voltage to 12kV, and collect the aluminum film at room temperature with a collection distance of 15cm. After 2 hours, the injection was stopped, and poly(lactic acid-glycolic acid) nanofiber membranes could be collected on the aluminum membrane;

[0036] 2) Dissolving 0.1 g of collagen in 100 mL of acetic acid solution with a volume concentration of 3%, to prepare an acetic acid solution with a mass concentration of 1 mg / mL collagen;

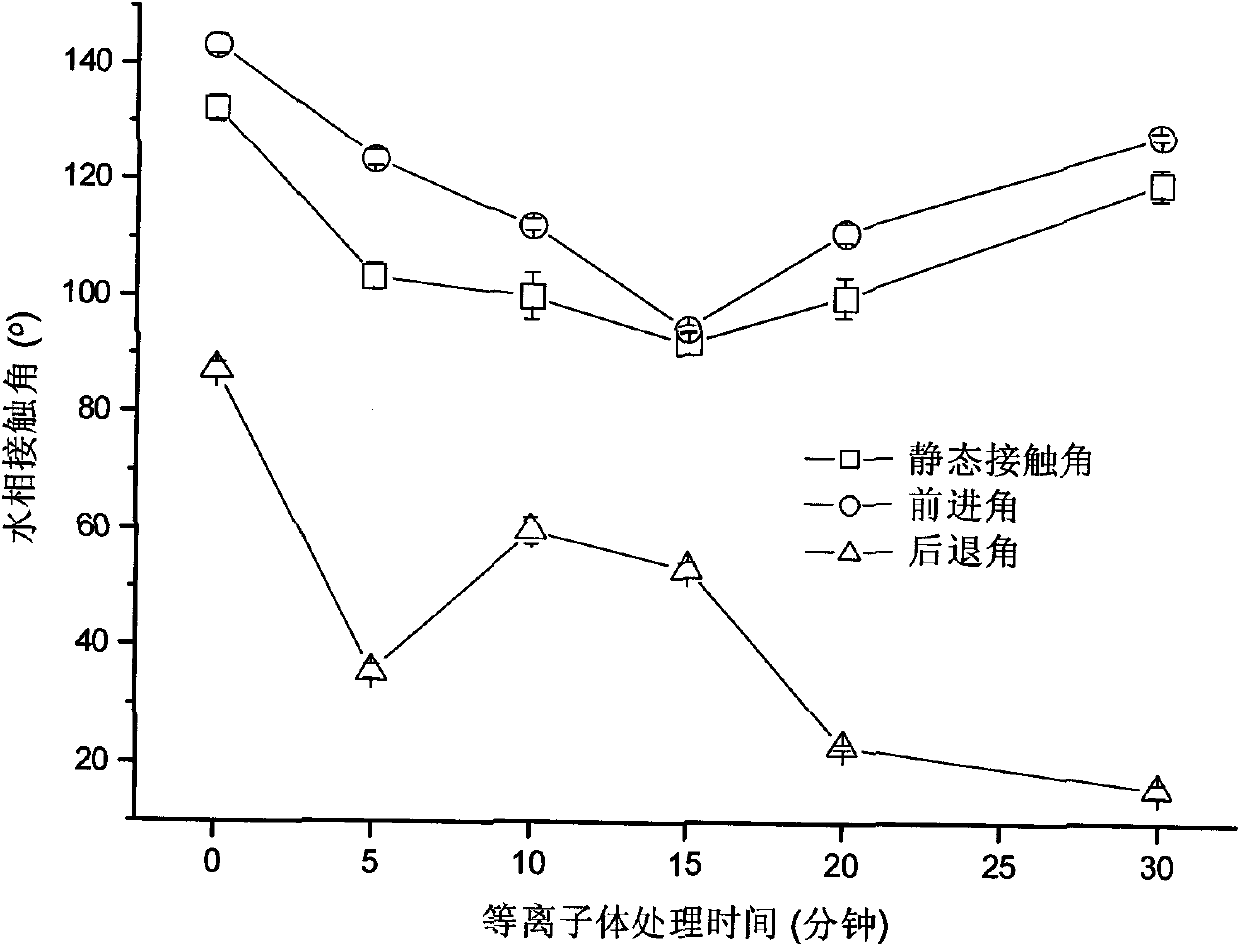

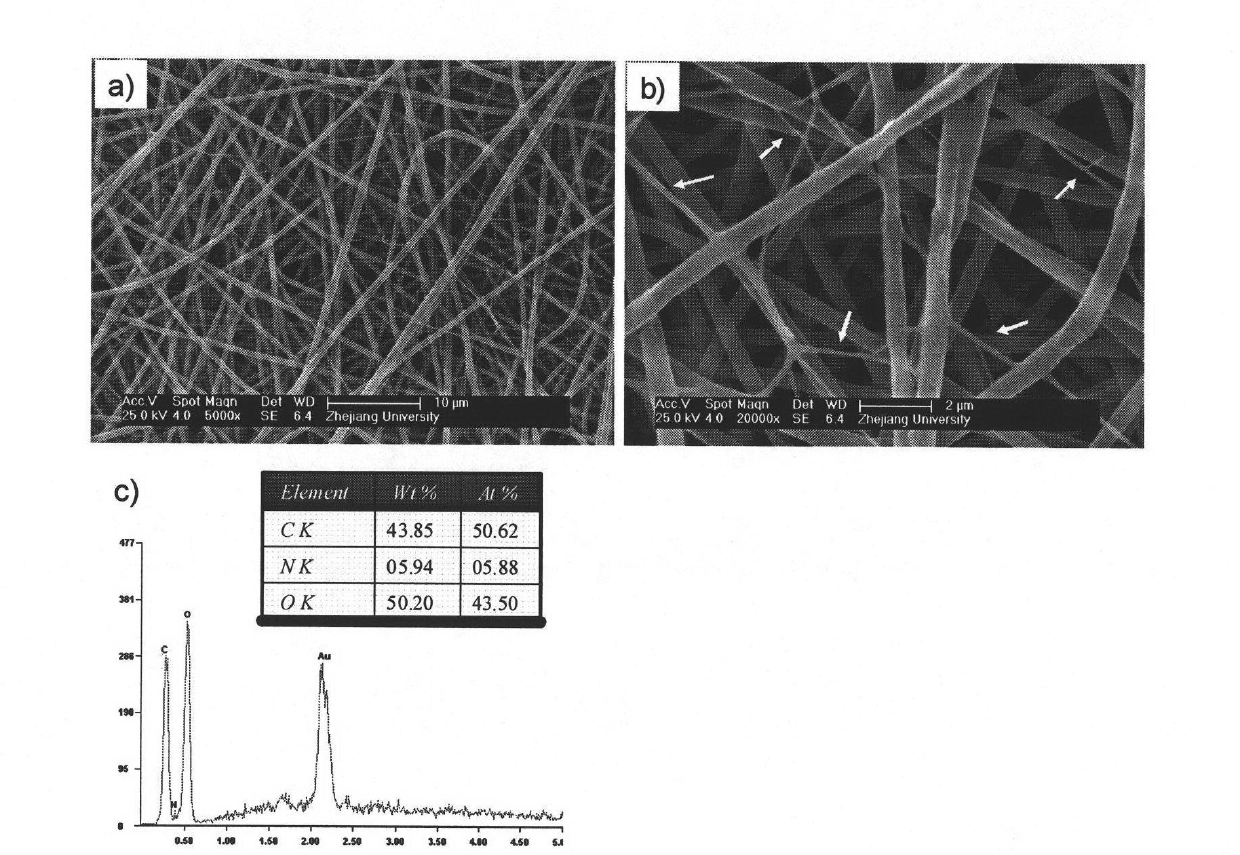

[0037] 3) Take 5 pieces of electrospun fiber membranes prepared in step 1), place them in a plasma discharge apparatus, set the power at 400W, and treat them for 5 minutes, 10 minutes, 15 minutes, 20 minutes, and 30 minutes respectively. Immediately immerse the...

example 2

[0044] Steps 1) to 2) are the same as steps 1) to 2) in Example 1.

[0045] Step 3) is the same as step 3) in Example 1, but the power of the plasma treatment is 50W.

[0046] Step 4) is the same as step 4) in Example 1 to obtain poly(lactic acid-glycolic acid) / collagen / hydroxyapatite composite fiber membrane.

[0047]Step 5) is the same as Step 5) in Example 1, but the ability of the fibrous membrane to induce osteogenic differentiation is evaluated with rabbit-derived bone marrow mesenchymal stem cells (MSCs), and the planting density of each well is controlled to be 6.0×10 3 / hole (i.e. 1.6×10 4 / cm 2 ). Part of the cells were cultured in DMEM medium containing 10% fetal bovine serum for up to 4 weeks, and some cells were cultured in DMEM medium containing 10% fetal bovine serum for 7 days before adding osteoinductive solution (containing 100nM dexamethasone, 10mM β- glycerol phosphate and 50 μg / mL vitamin C ascorbic acid) in DMEM medium containing 10% fetal bovine seru...

example 3

[0049] Steps 1) to 2) are the same as steps 1) to 2) in Example 1.

[0050] Step 3) is the same as step 3) in Example 1, but the poly(lactic acid-glycolic acid) fiber membrane is coated with collagen after plasma treatment for 10 minutes.

[0051] Step 4) is the same as step 4) in Example 1 to obtain poly(lactic acid-glycolic acid) / collagen / hydroxyapatite composite fiber membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com