Intelligent anticorrosive and self-repairing coating and preparation method thereof

A self-healing and intelligent technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., to improve corrosion resistance and service life, green and simple preparation process, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

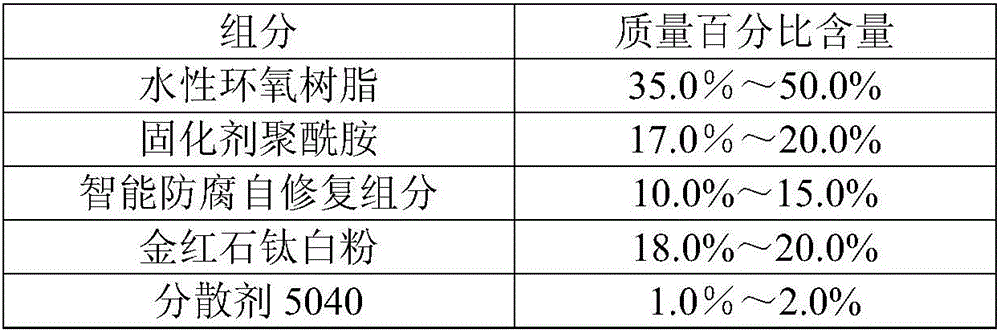

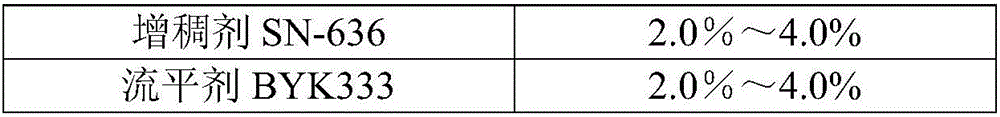

[0034] An intelligent anti-corrosion self-healing coating, which uses water-based epoxy resin as the base material, adds intelligent anti-corrosion self-healing microcapsules and various pigments and fillers and additives, and its components and their mass percentages are as follows:

[0035] components Mass percentage content Waterborne epoxy resin 35.0% Curing agent polyamide 20.0% Intelligent anti-corrosion self-healing components 15.0% Rutile Titanium Dioxide 20.0% Dispersant 5040 2.0% Thickener SN-636 4.0% Leveling agent BYK333 4.0%

[0036] Take 6g of urea, 1g of Triton X100 emulsifier, 0.2g of resorcinol and 0.2g of ammonium chloride and add them into 250mL of deionized water, mix and stir evenly, and adjust the pH of the mixture to 2.5-4 with 1mol / l hydrochloric acid. Then add 10g of tallow tree oil, the core material, and stir to mix. The stirring speed is 500rpm, and the stirring time is 30min. Then, the resulti...

Embodiment 2

[0050] An intelligent anti-corrosion self-healing coating, which uses water-based epoxy resin as the base material, adds intelligent anti-corrosion self-healing microcapsules and various pigments and fillers and additives, and its components and their mass percentages are as follows:

[0051] components Mass percentage content Waterborne epoxy resin 38.0% Curing agent polyamide 18.0% Intelligent anti-corrosion self-healing components 14.0% Rutile Titanium Dioxide 20.0% Dispersant 5040 2.0% Thickener SN-636 4.0% Leveling agent BYK333 4.0%

[0052] Weigh 7g of urea, 2g of Triton X100 emulsifier, 0.5g of resorcinol and 0.5g of ammonium chloride and add them into 250mL of deionized water, mix well, and adjust the pH of the mixture to 2.5-4 with 1mol / l hydrochloric acid. , then add 15g core material Chinese tallow tree oil, stir and mix, the stirring speed is 600rpm, the stirring time is 20min, then the resulting mixed solutio...

Embodiment 3

[0055] An intelligent anti-corrosion self-healing coating, which uses water-based epoxy resin as the base material, adds intelligent anti-corrosion self-healing microcapsules and various pigments and fillers and additives, and its components and their mass percentages are as follows:

[0056] components Mass percentage content Waterborne epoxy resin 43.0% Curing agent polyamide 18.0% Intelligent anti-corrosion self-healing components 13.0% Rutile Titanium Dioxide 19.0% Dispersant 5040 1.0% Thickener SN-636 3.0% Leveling agent BYK333 3.0%

[0057] Weigh 8g of urea, 3g of Triton X100 emulsifier, 1g of resorcinol and 1g of ammonium chloride and add them to 250mL deionized water, mix and stir evenly, adjust the pH of the mixture to 4 with 1mol / l hydrochloric acid, and then add 20g The core material Chinese tallow tree oil is stirred and mixed, the stirring speed is 500rpm, and the stirring time is 15min. Then the resulting mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com