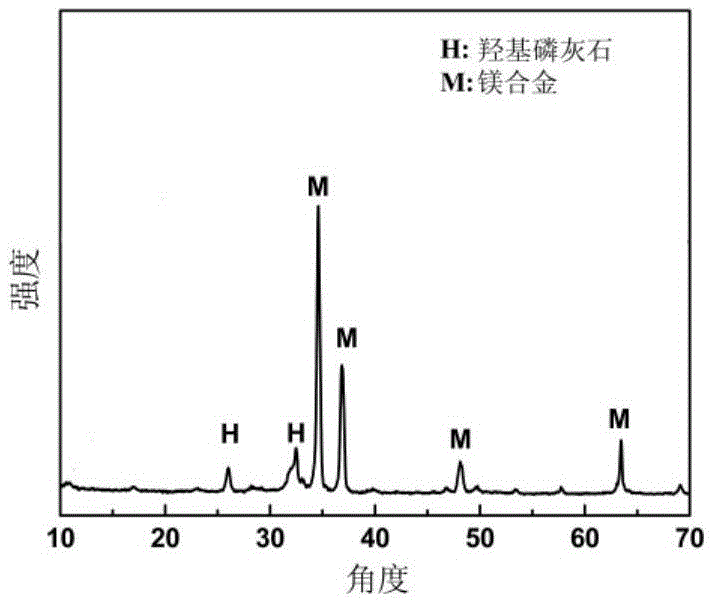

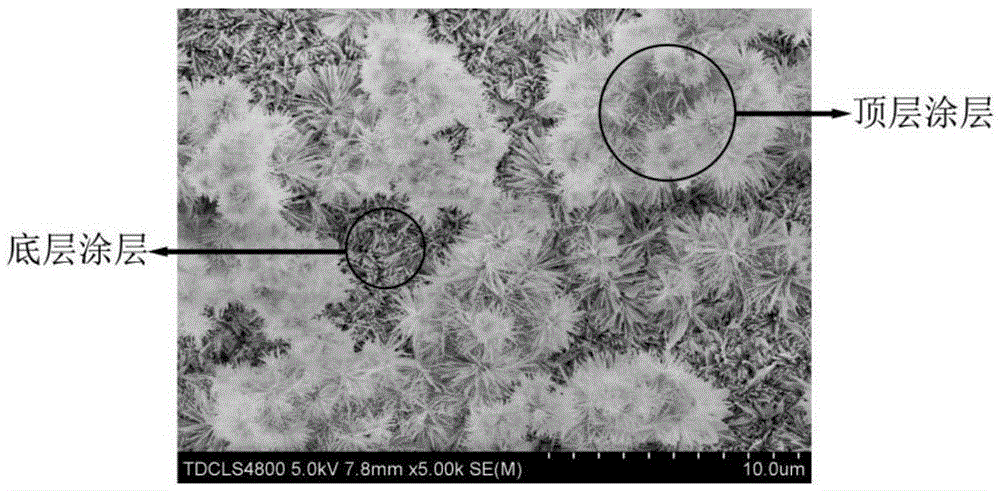

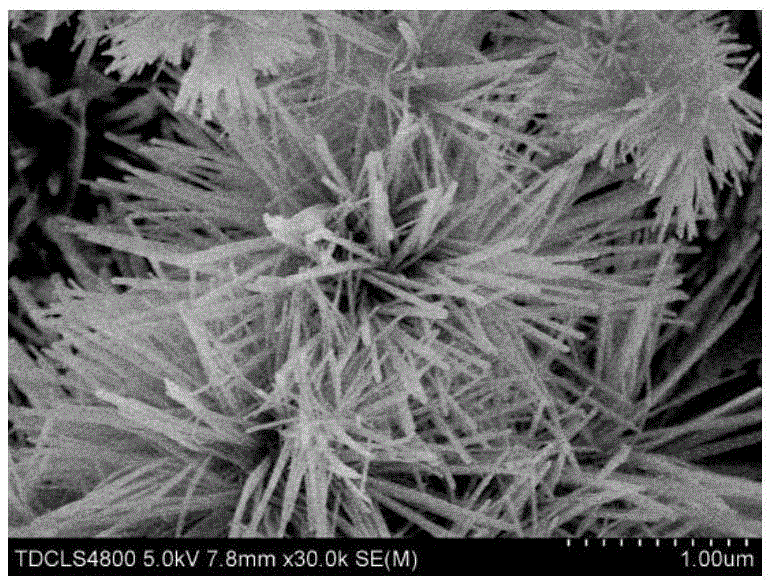

Two-layer crystal whisker-shaped fluorine-doped hydroxyapatite coating on magnesium alloy and microwave preparation method thereof

A technology of hydroxyapatite and magnesium alloy, which is applied in coating, medical science, prosthesis, etc., to achieve the effects of weakening dissolution and cracking, improving corrosion resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) AZ31 magnesium alloy was processed into a block of 10mm×10mm×2mm, polished to 2000 mesh with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water and ethanol for 10min, and dried with hot air.

[0037] (2) Prepare 150 mL of 2 mol / L NaOH deionized aqueous solution. Soak 10 polished magnesium alloys in NaOH solution at 60°C for 0.5h, then rinse the magnesium alloy samples with deionized water and dry them.

[0038] (3) with Ca(NO 3 ) 2 Prepare Ca for Ca source 2+ Aqueous solution, as Na 2 HPO 4 Preparation of PO for P source 4 3- Aqueous solution, using NaF as F source to prepare F - aqueous solution. Then PO 4 3- The aqueous solution was added dropwise with Ca 2+ In aqueous solution, stir evenly to form A solution; mix F - The aqueous solution was added dropwise to solution A, and stirred evenly to form solution B; finally, the pH value of solution B was adjusted to 6.0 with 10M dilute nitric acid, and magnetically stirred for 1 hour to ...

Embodiment 2

[0042] (1) AZ91 magnesium alloy was processed into a block of 10mm×10mm×2mm, polished to 1200 mesh with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water and ethanol for 6 minutes, and dried with hot air.

[0043] (2) Prepare 150 mL of 0.5 mol / L NaOH deionized aqueous solution. Soak five polished magnesium alloys in NaOH solution at 70°C for 1 hour, then rinse the magnesium alloy samples with deionized water and dry them.

[0044] (3) with CaCl 2 Prepare Ca for Ca source 2+ Aqueous solution, as NaH 2 PO 4 Preparation of PO for P source 4 3- aqueous solution. Preparation of F with KF as F source - aqueous solution. Then PO 4 3- The aqueous solution was added dropwise with Ca 2+ In the aqueous solution, stir evenly to form A solution, and mix F - The aqueous solution was added dropwise to the A solution, and stirred evenly to obtain the B solution. Finally, the pH value of solution B was adjusted to 5.5 with 7M dilute hydrochloric acid, and magn...

Embodiment 3

[0048] (1) AZ61 magnesium alloy was processed into a block of 10mm×10mm×2mm, polished to 1500 mesh with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water and ethanol for 8 minutes, and dried with hot air.

[0049](2) Prepare 150 mL of 1.5 mol / L NaOH deionized aqueous solution. Soak 15 polished magnesium alloys in NaOH solution at 80°C for 1.5h, then rinse the magnesium alloy samples with deionized water and dry them.

[0050] (3) with Ca(CH 3 COO) 2 Prepare Ca for Ca source 2+ Aqueous solution, as NaH 2 PO 4 Preparation of PO for P source 4 3- Aqueous solution, using NaF as F source to prepare F - aqueous solution. Then PO 4 3- The aqueous solution was added dropwise with Ca 2+ In the aqueous solution, stir evenly to form A solution, and mix F - The aqueous solution was added dropwise to solution A, stirred evenly to form solution B, and finally the pH value of solution B was adjusted to 7.0 with 4M acetic acid, and magnetically stirred for 0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com