Method for preparing aqueous solution of single-layer grapheme oxide

An aqueous solution and graphene technology, applied in the field of nanomaterials, can solve the problems of unfriendly environment, long processing time, and difficult removal of organic solvents, and achieve the effects of fast and efficient preparation technology, efficient preparation technology, and dispersion time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using the Staudenmaier method, natural flake graphite was added to a mixture of 98wt% concentrated sulfuric acid and 65wt% nitric acid, wherein the volume ratio of concentrated sulfuric acid and nitric acid was 13:7. Stirring and adding potassium nitrate, controlling the temperature of the reaction solution to 0-10° C., stirring the reactant for 24 hours to obtain graphite oxide. Dilute the reactant, filter, and wash thoroughly with deionized water until there is no SO in the filtrate 4 2- , then dried, ground and sieved to obtain graphite oxide.

[0038] Weigh 50 mg of graphite oxide in a beaker, irradiate for 15 seconds under a microwave with a power of 100 W and a frequency of 2.45 GHz, add 100 ml of deionized water, add 0.1 ml of ammonia water with a mass percentage of 38%, and shake at 200 Hz for 5 minutes to obtain a brownish-red clarification Graphene oxide solution, the solution did not have any precipitation after standing for 30 days, and the sample was pour...

Embodiment 2

[0040] Using the Hummer method, take 98% concentrated sulfuric acid, cool it in an ice-water bath, add a certain amount of natural flake graphite, NaNO 3 and KMnO 4 , control the temperature of the reaction solution at 0-10°C, stir the reaction for 5 hours, then carry out the high-temperature reaction, control the temperature of the reaction solution within 100°C, and continue stirring for 30 minutes. Dilute the reaction solution with deionized water and add appropriate amount of H 2 o 2 , filtered while hot, fully washed with deionized water until there was no SO in the filtrate 4 2- . Then dry, grind and sieve to obtain graphite oxide.

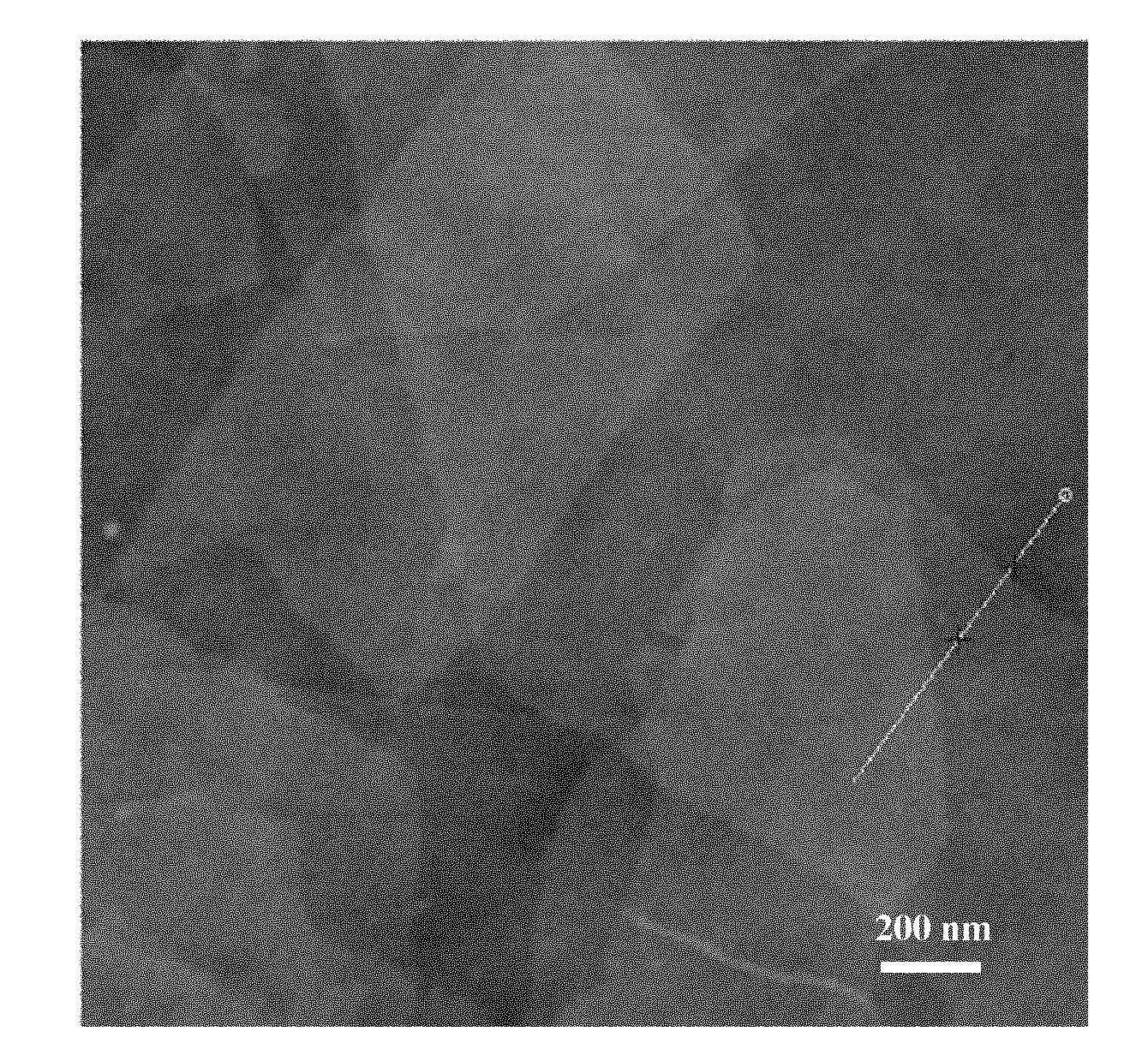

[0041] Weigh 30mg of graphite oxide in a beaker, irradiate for 10 seconds under a microwave with a power of 500W and a frequency of 2.45GHz, add 100ml of deionized water, add 1ml of 1M KOH solution, and ultrasonicate for 2 minutes at a power of 100W to obtain brown-red clarified graphite oxide olefin solution, the sample was observed b...

Embodiment 3

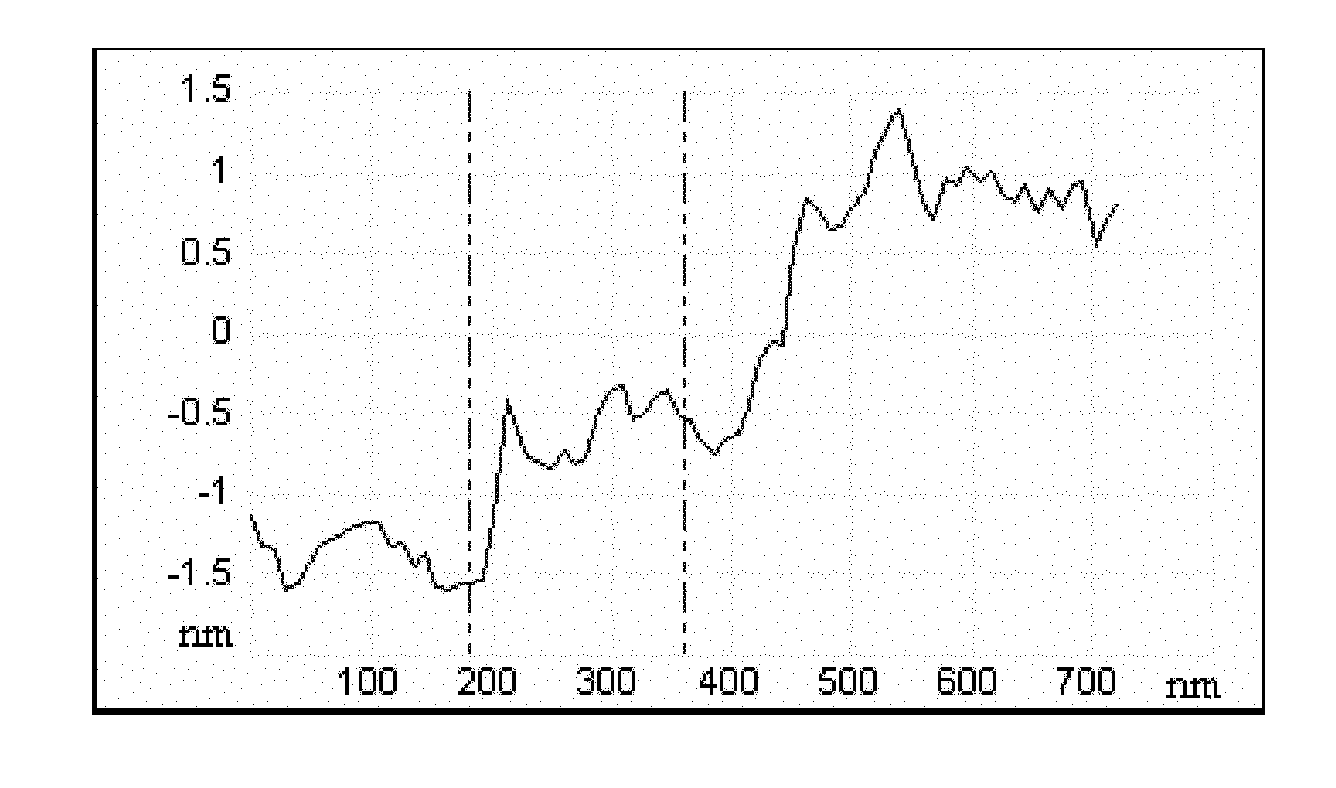

[0043] The preparation of graphite oxide is the same as that in Example 1. Weigh 500 mg of graphite oxide in a beaker, and irradiate it under a microwave with a frequency of 1000 W and a frequency of 2.45 GHz for 6 seconds, add 100 ml of deionized water, and add 1 ml of 1M Na 2 CO 3 solution, under 200W power, ultrasonic for 5 minutes to obtain a brown-red clear graphene oxide solution, and the solution did not have any precipitation after standing for 30 days. The clear solution was spin-coated on a polished silicon substrate for field emission scanning electron microscopy, and the results were as follows: Figure 5 shown. The thickness of graphene oxide flakes is only about 1 nanometer, which is a single layer structure. Overall, the preparation time from graphite oxide to single-layer graphene oxide aqueous solution is less than 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com