Nano-composite air electrode catalyst for zinc-air battery and preparation method of nano-composite air electrode catalyst

A zinc-air battery, nano-composite technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as expensive cost, harsh use environment, restrictions, etc., achieve improved wetting performance, simple preparation process, and overcome the preparation process. complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the nanocomposite air electrode catalyst that the present invention proposes for zinc-air battery comprises the following steps:

[0033](1) Put 0-10g of carbon nanotubes into 200-500mL of acetone solution for ultrasonic cleaning for 120-180min, then put the cleaned carbon nanotubes into 500-1000mL of deionized water for ultrasonic cleaning for 120-180min, and finally wash the put the carbon nanotubes into 500-1000mL of absolute ethanol and ultrasonically clean them for 120-180min, obtain modified carbon nanotubes after filtration, dry the modified carbon nanotubes at a constant temperature of 80-150°C for 6-15h, and dry the The loose modified carbon nanotubes are screened, and the particle size range of the modified carbon nanotubes is selected to be 35 μm to 150 μm, preferably 75 μm to 150 μm, and set aside;

[0034] (2) Put 17.5-27.5g carbon material into 500-1000mL acetone solution and ultrasonically clean it for 60-150min, then put the cle...

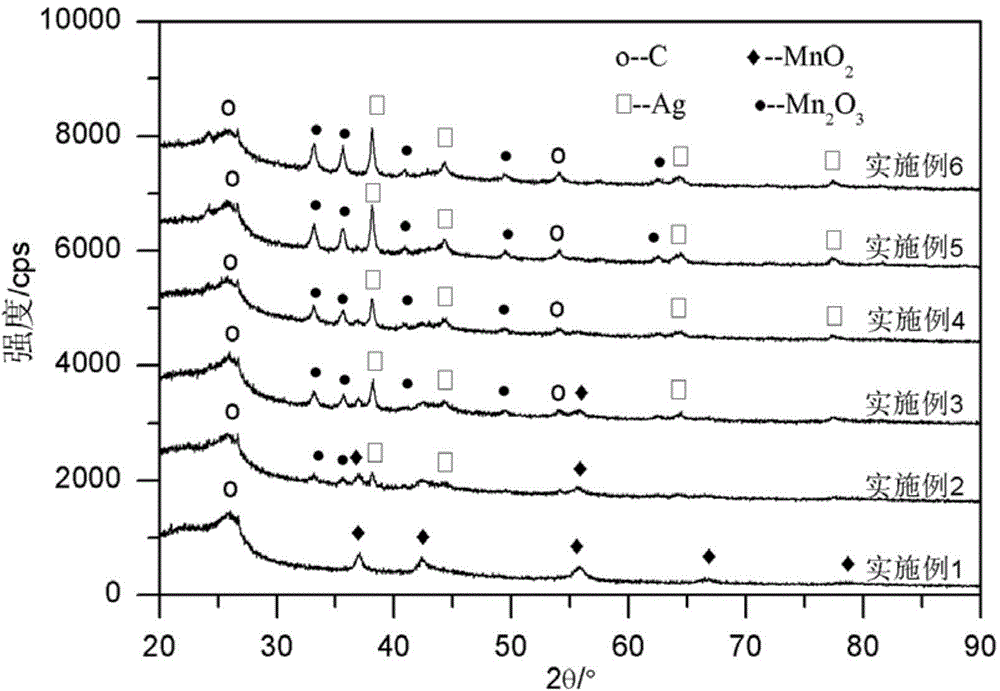

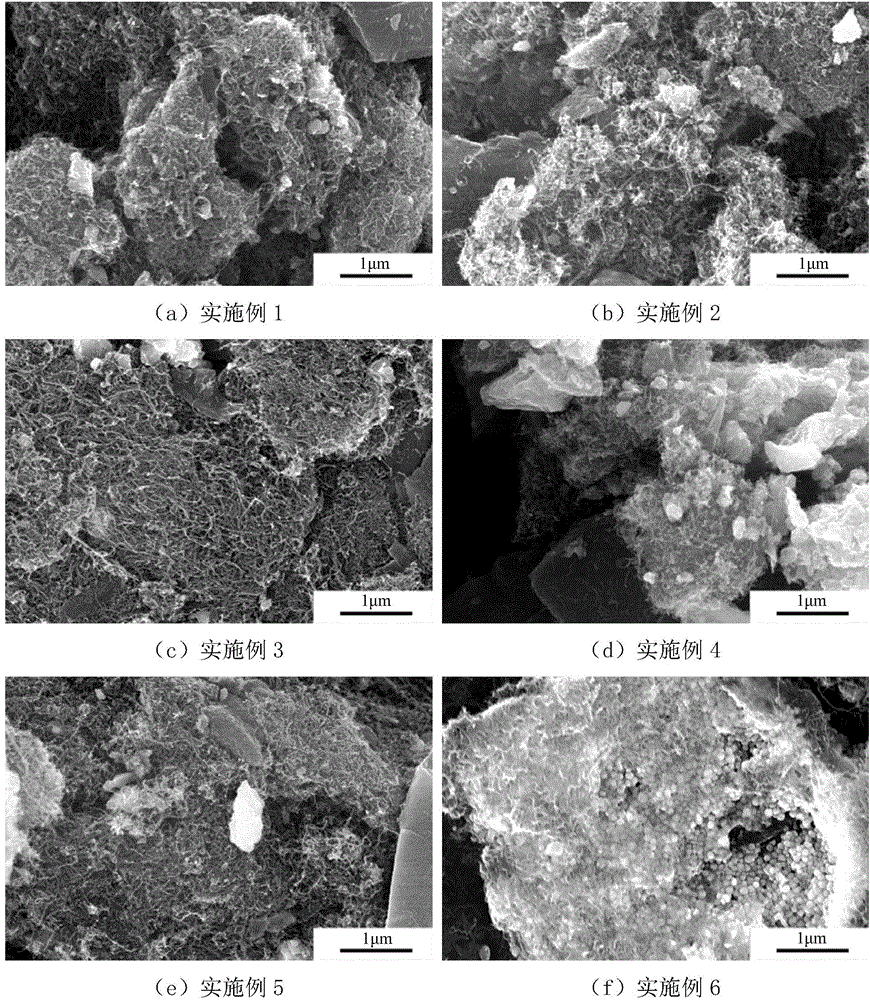

Embodiment 1

[0041] Put 10g of carbon nanotubes in 400mL of acetone solution for ultrasonic cleaning for 180min, then put the cleaned carbon nanotubes in 800mL of deionized water for ultrasonic cleaning for 180min, and finally put the cleaned carbon nanotubes in 800mL of absolute ethanol for ultrasonic cleaning After 180 minutes, the modified carbon nanotubes were obtained after filtration. The modified carbon nanotubes were dried at a constant temperature of 140°C for 7 hours, and the dry and loose modified carbon nanotubes were screened to select the particle size range of the modified carbon nanotubes. 75 μm ~ 150 μm, set aside; then take 10g graphene and 10g Super S carbon black in 800mL acetone solution for ultrasonic cleaning for 150min, then put the cleaned graphene and Super S carbon black into 1500mL deionized water for ultrasonic cleaning Clean for 150min, finally put the cleaned graphene and Super S type carbon black into 1500mL absolute ethanol and ultrasonically clean for 150mi...

Embodiment 2

[0044] Put 10g of carbon nanotubes into 300mL of acetone solution for ultrasonic cleaning for 120min, then put the cleaned carbon nanotubes into 700mL of deionized water for ultrasonic cleaning for 120min, and finally put the cleaned carbon nanotubes into 700mL of absolute ethanol for ultrasonic cleaning After filtering for 120 minutes to obtain modified carbon nanotubes, dry the modified carbon nanotubes at a constant temperature of 100°C for 10 hours, sieve the dry and loose modified carbon nanotubes, and select the particle size range of the modified carbon nanotubes 75 μm ~ 150 μm, set aside; then take 10 g of activated carbon and 13 g of acetylene black in 600 mL of acetone solution for ultrasonic cleaning for 90 min, then put the cleaned activated carbon and acetylene black into 1800 mL of deionized water for ultrasonic cleaning for 90 min, and finally put the cleaned Activated carbon and acetylene black were ultrasonically cleaned in 1800mL of absolute ethanol for 90 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com