Preparation method of flexible metal photonic crystal

A metal photonic crystal, flexible substrate technology, applied in nano-optics, optical waveguide light guide, nanotechnology and other directions, to achieve the effect of simple preparation method and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

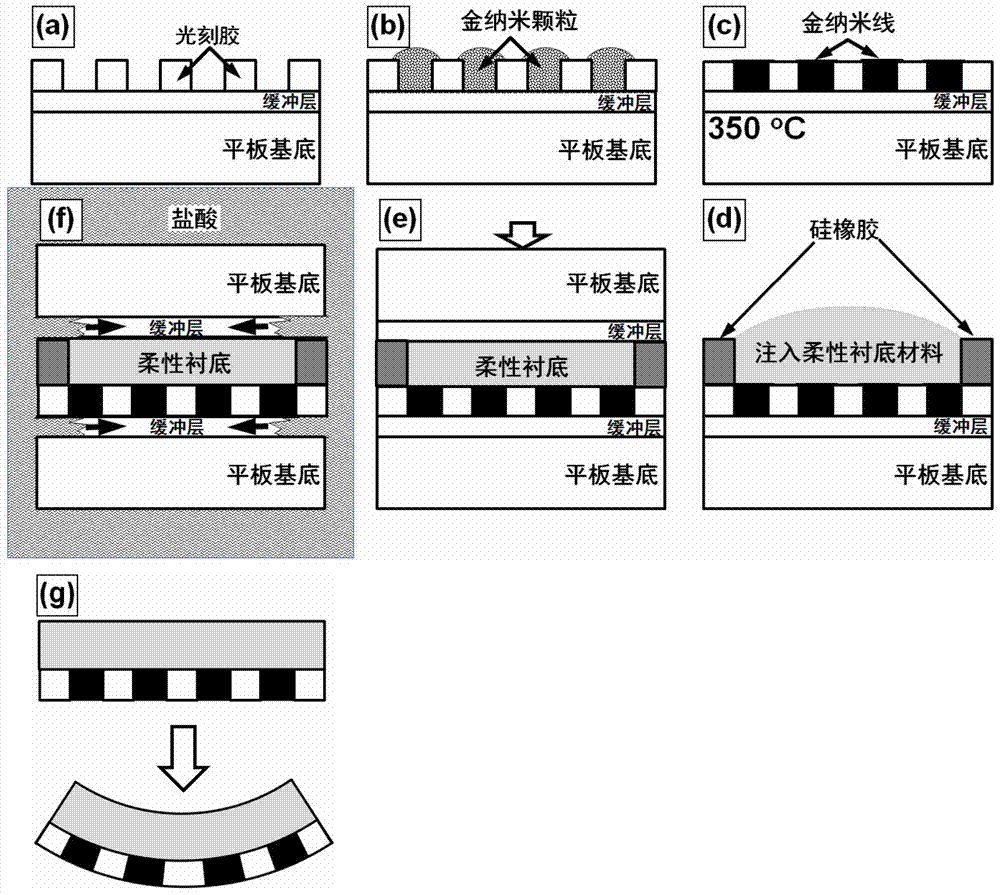

[0038] The present invention will be further described in conjunction with examples, but the present invention is not limited to the following examples. Example 1: Preparation of flexible metal photonic crystals.

[0039] (1) Spin-coat S1805 photoresist at 2000rpm on a glass substrate coated with a 200nm indium tin oxide (ITO) film.

[0040] (2) He-Cd laser with a wavelength of 325nm is used to carry out interference lithography in the S1805 photoresist film. The angle between the two laser beams participating in the interference lithography is controlled to be 48 degrees to ensure that the period of the photoresist grating is 400nm. The exposure time was controlled by an optical shutter for 20 s. Then develop in the developer for 6s. Then rinse with distilled water for 30 s. The cleaned sample was dried in an oven at 120° C. to obtain a photoresist grating structure.

[0041] (3) A colloidal solution of chemically synthesized gold nanoparticles in xylene with a concentra...

Embodiment 2

[0051] Example 2: Microstructure testing of flexible metal photonic crystals.

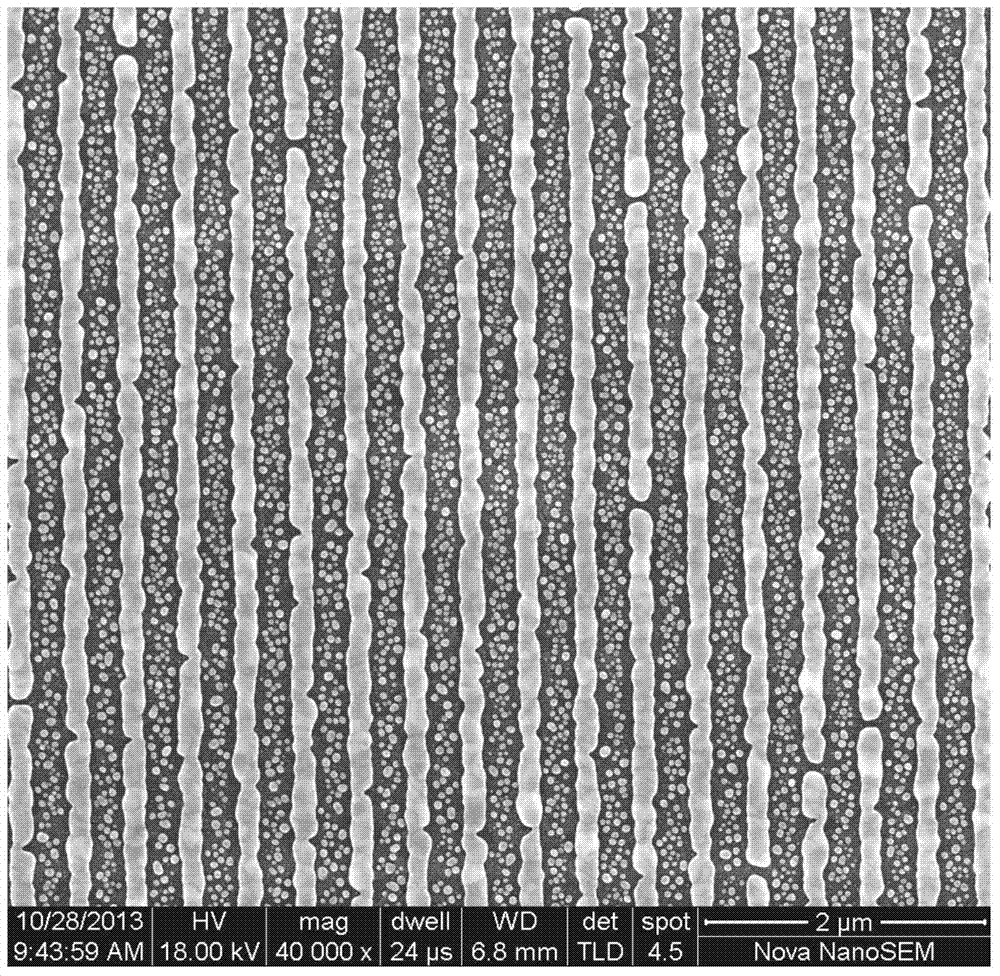

[0052] (1) adopt Nova NanoSEM type scanning electron microscope to measure the microstructure of the metal photonic crystal prepared in example 1 step 4, such as image 3 shown. Metal photonic crystals have a period of about 400nm and consist of periodically arranged gold nanowires. The average width of gold nanowires is about 165 nm. Some gold nanoparticles remain between the gold nanowires, and the diameters thereof are all less than 70nm.

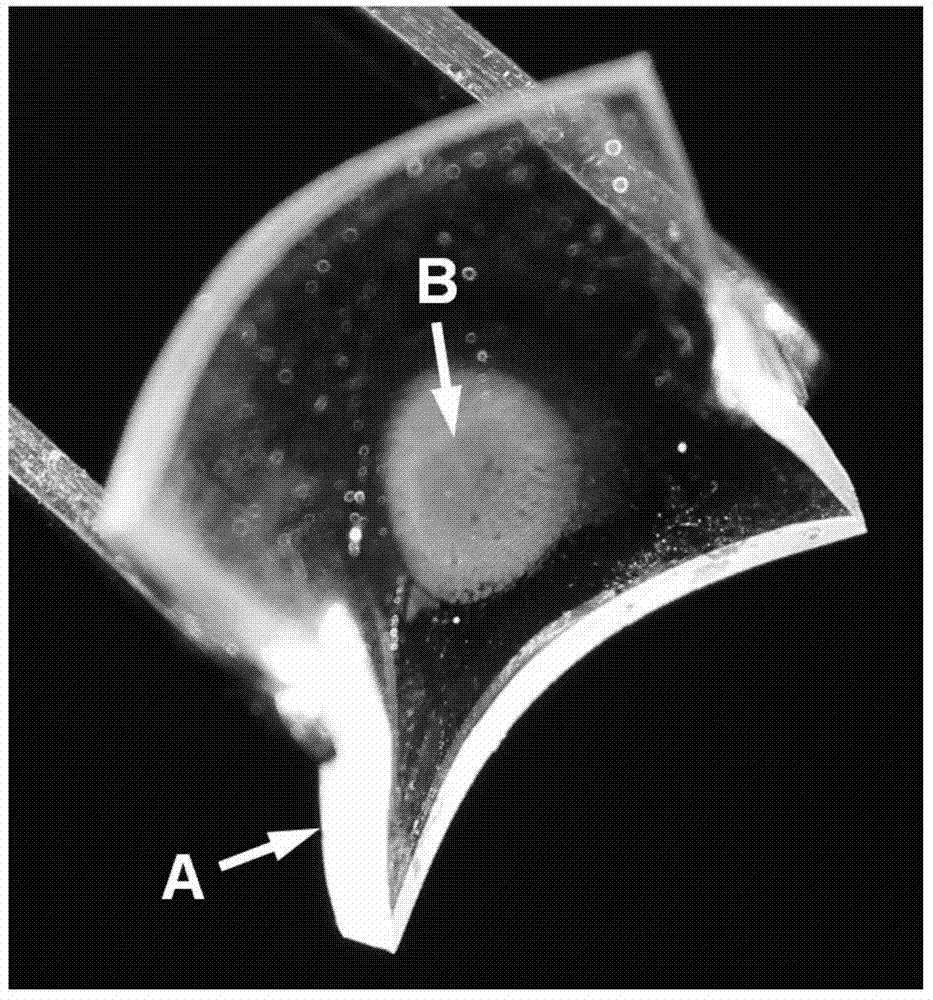

[0053] (2) The metal photonic crystal structure transferred to PDMS was measured by FEI Phenom desktop scanning electron microscope. Since the PDMS substrate is non-conductive, it is impossible to complete high-resolution electron microscopic measurement, that is, the testing instrument used in step (1) cannot be used. Test results such as Figure 4 shown. Since what is measured at this time is the bottom surface of the metal photonic crystal prepared o...

Embodiment 3

[0055] Example 3: Stretching realization of flexible metal photonic crystal and its stretching deformation sensor experiment.

[0056] (1) A self-built flexible photonic crystal tensile test platform is used, and the schematic diagram of the device is as follows Figure 6 As shown, the two ends of the PDMS substrate of the flexible metal photonic crystal are respectively fixed on two independent precision translation stages. Move the two translation stages separately to make them in the middle of the scale range, and add a certain initial stress to the PDMS substrate to ensure that the substrate is flattened. Except for the stretching direction, the substrate has no deformation and stress in other directions.

[0057] (2) A broadband white light source is focused to irradiate the metal photonic crystal on the PDMS substrate, and the transmitted light is accepted by the probe of the fiber optic spectrometer in order to measure the transmission spectrum.

[0058] (3) First col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com