Multi-point touch grapheme capacitive touch screen and production method thereof

A capacitive touch screen and graphene technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of inability to realize multi-touch and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] In addition, the present invention also discloses a preparation method of the capacitive touch screen, comprising the following steps:

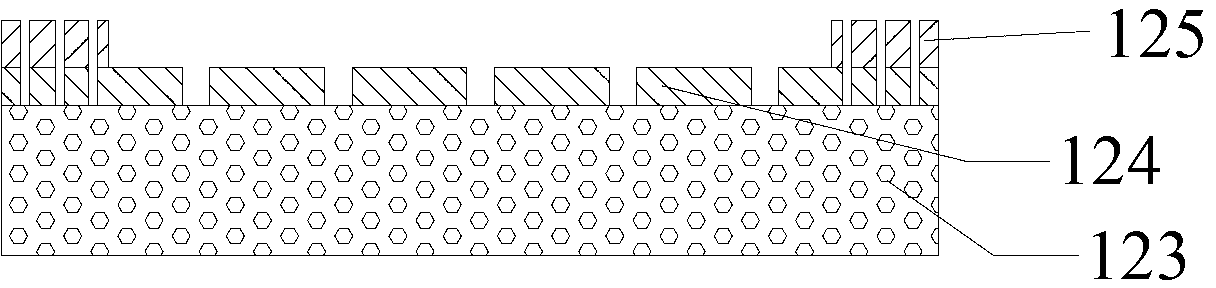

[0089] (1) providing two substrates 123;

[0090] (2) Prepare a graphene transparent conductive film 124, and transfer the graphene transparent conductive film 124 to the substrate 123, so that the entire plate on the substrate 123 is covered with the graphene transparent conductive film 124;

[0091] (3) Depositing the metal thin film 125 on the lead electrode area 220 on the substrate obtained in step (2);

[0092] (4) patterning the two substrates obtained in step (3) on which the graphene transparent conductive film 124 and the metal film 125 are deposited sequentially, to obtain the induction plate (121, 122); wherein, the pattern extends along the first direction is the first sensing plate 121, and the pattern extending along the second direction is the second sensing plate 122;

[0093] (5) Bond the first sensing board 121 and...

Embodiment 1

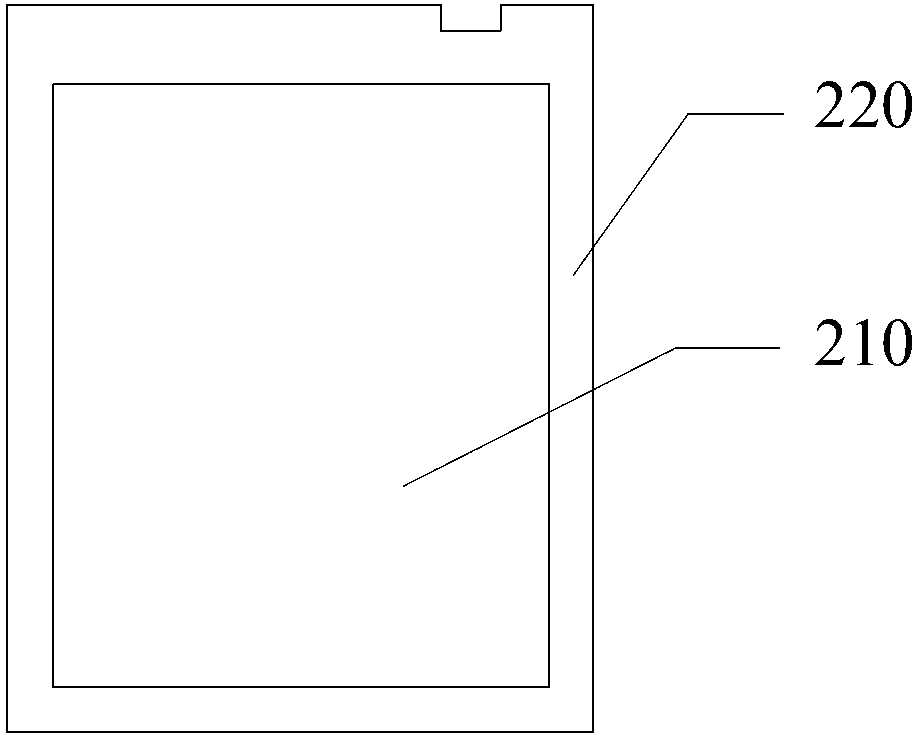

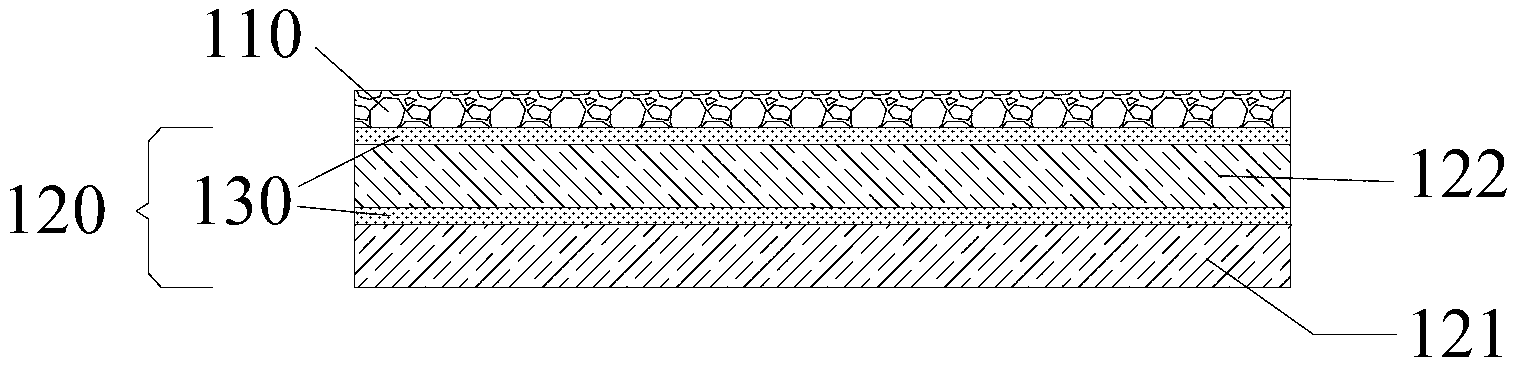

[0097] A capacitive touch screen capable of multi-touch operation based on graphene transparent conductive film, including from bottom to top:

[0098] The substrate 1223 of the second induction board 122, the graphene transparent conductive film 1224 of the second induction board 122, the metal film 1225 of the lead electrode area of the second induction board 122;

[0099] OCA optical glue 130;

[0100] The substrate 1213 of the first induction board 121, the graphene transparent conductive film 1214 of the first induction board 121, the metal film 1215 of the lead electrode area of the first induction board 121;

[0101] OCA optical glue 130;

[0102] and a glass cover 110;

[0103] Wherein, the leads of the lead electrode regions 220 of the first sensing board 121 and the second sensing board 122 are connected to the IC chip 140 through the flexible circuit board 150 .

[0104] Figure 5 It is a schematic cross-sectional structure diagram of the capacitive touch sc...

Embodiment 2

[0113] A capacitive touch screen capable of multi-touch operation based on a graphene transparent conductive film, the difference from Embodiment 1 is that the order of the second sensing board and the first sensing board is reversed, and the capacitive touch screen is composed of the following Supreme includes, in order:

[0114] The substrate 1213 of the first induction board 121, the graphene transparent conductive film 1214 of the first induction board 121, the metal film 1215 of the lead electrode area of the first induction board 121;

[0115] OCA optical glue 130;

[0116] The substrate 1223 of the second induction board 122, the graphene transparent conductive film 1224 of the second induction board 122, the metal film 1225 of the lead electrode area of the second induction board 122;

[0117] OCA optical glue 130;

[0118] and a glass cover 110;

[0119] Wherein, the lead wires of the lead electrode areas of the first sensing board 121 and the second sensing bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com