Austenitic stainless steel composite resinite manufacture method

A technology of austenitic stainless steel and composite resin, which is applied in the direction of metal material coating process, etc., can solve the problems of poor adhesion and poor composite property of metal and resin composition, and achieve long service life, strong adhesion, The effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

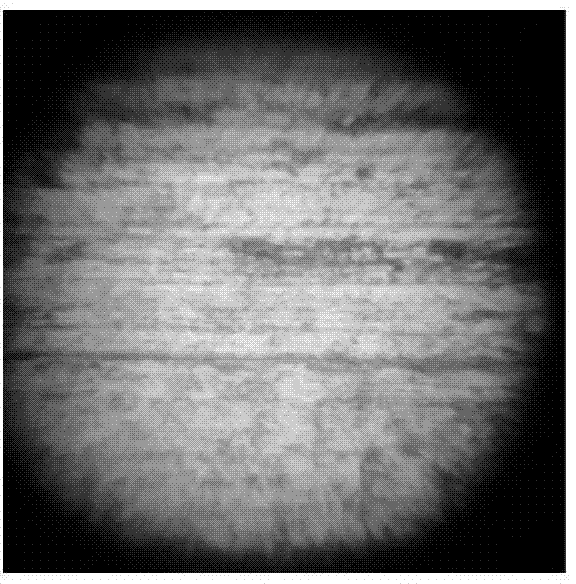

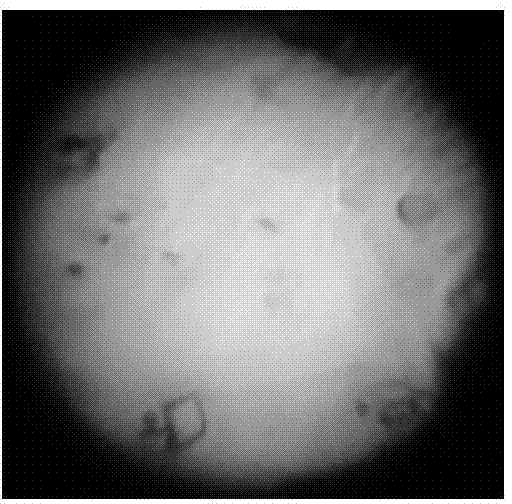

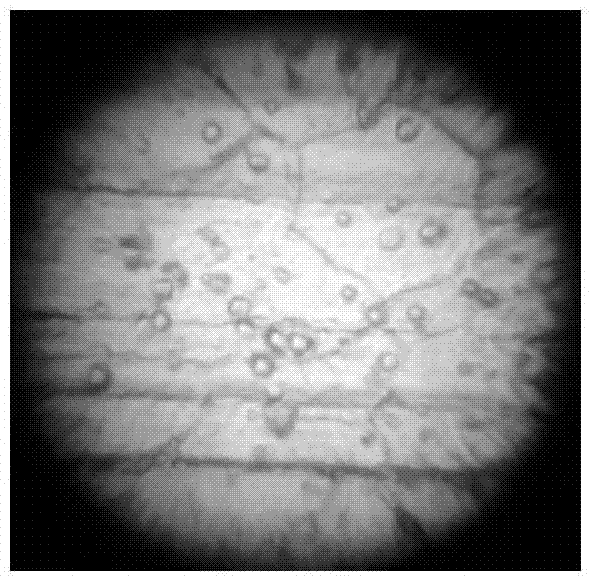

Image

Examples

Embodiment 1

[0058] A method for manufacturing an austenitic stainless steel composite resin body, comprising the following preparation steps:

[0059] S1. Surface pretreatment of austenitic stainless steel, including degreasing and degreasing treatment and water washing

[0060] Degreasing and degreasing treatment: immersing the austenitic stainless steel in solution 1 containing a water-based active degreasing and degreasing agent at a temperature of 70°C for 90 seconds; wherein, the volume percentage concentration of the water-based active degreasing and degreasing agent is 10%;

[0061] Water washing: Soak the austenitic stainless steel after degreasing and degreasing treatment in pure water with conductivity ≤20us / cm at room temperature for 10 seconds.

[0062] S2, chromium oxide cadmium film damage treatment

[0063] Soak the austenitic stainless steel washed by S1 in solution 2 at a temperature of 50°C for 1 minute, and the solution 2 is an inorganic alkaline solution with a concen...

Embodiment 2

[0075] A method for manufacturing an austenitic stainless steel composite resin body, comprising the following preparation steps:

[0076] S1. Surface pretreatment of austenitic stainless steel, including degreasing and degreasing treatment and water washing

[0077] Degreasing and degreasing treatment: immersing the austenitic stainless steel in solution 1 containing a water-based active degreasing and degreasing agent at a temperature of 15°C for 600 seconds; wherein, the volume percentage concentration of the water-based active degreasing and degreasing agent is 10%;

[0078] Water washing: Soak the austenitic stainless steel after degreasing and degreasing treatment in pure water with conductivity ≤20us / cm at room temperature for 60 seconds.

[0079] S2, chromium oxide cadmium film damage treatment

[0080] Soak the austenitic stainless steel washed by S1 in solution 2 at a temperature of 50°C for 6 minutes, the solution 2 is an inorganic alkaline solution with a concentr...

Embodiment 3

[0094] A method for manufacturing an austenitic stainless steel composite resin body, comprising the following preparation steps:

[0095] S1. Surface pretreatment of austenitic stainless steel, including degreasing and degreasing treatment and water washing

[0096] Degreasing and degreasing treatment: immersing the austenitic stainless steel in solution 1 containing a water-based active degreasing and degreasing agent at a temperature of 50°C for 300 seconds; wherein, the volume percentage concentration of the water-based active degreasing and degreasing agent is 5%;

[0097] Water washing: Soak the austenitic stainless steel after degreasing and degreasing treatment in pure water with conductivity ≤20us / cm at room temperature for 50 seconds.

[0098] S2, chromium oxide cadmium film damage treatment

[0099] Soak the austenitic stainless steel washed by S1 in solution 2 at a temperature of 30°C for 4 minutes, and the solution 2 is an inorganic alkaline solution with a conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com