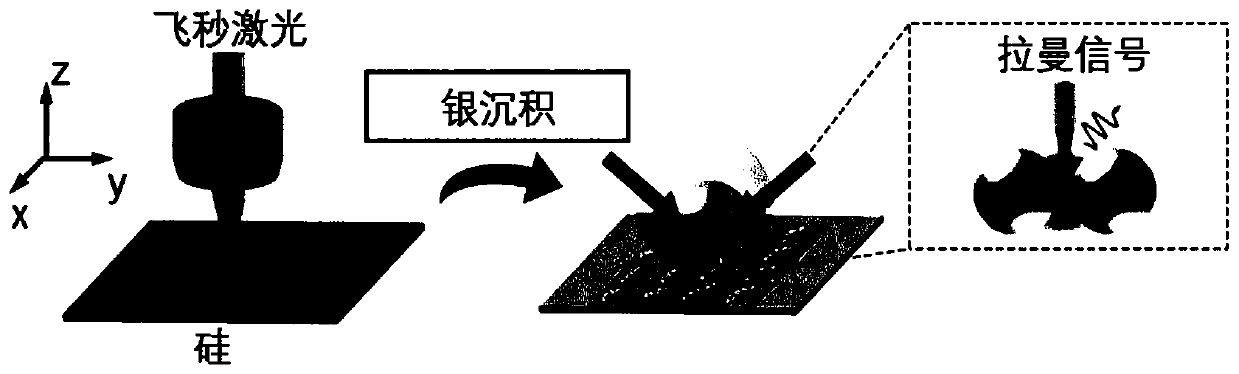

Preparation method of surface-enhanced Raman substrate with layered micro/nano structure

A nanostructured, surface-enhanced technology, applied in Raman scattering, material analysis, material excitation analysis, etc., to achieve the effect of economical preparation process, broad application prospects, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

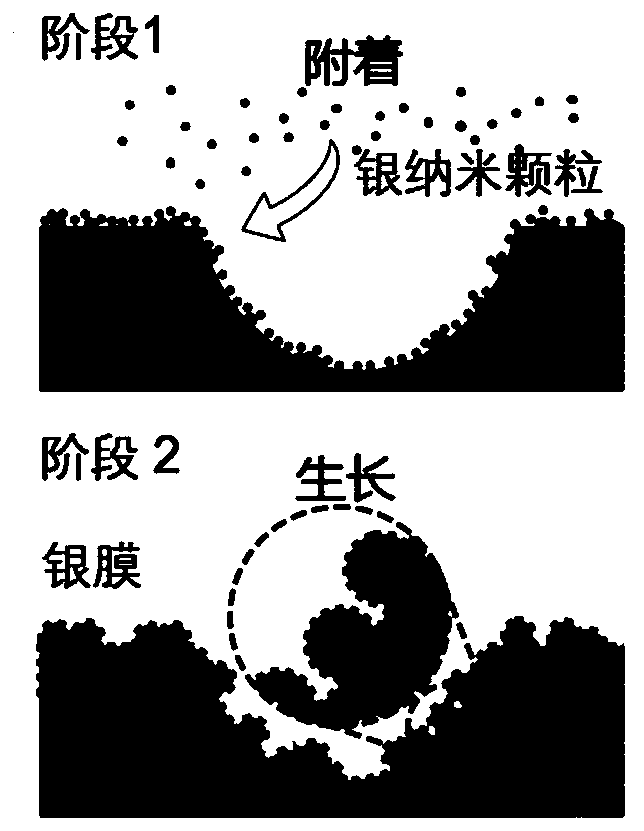

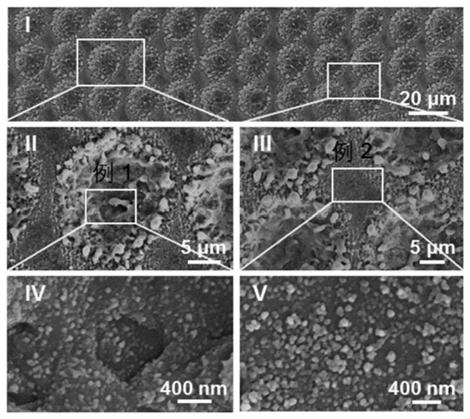

[0040] A surface-enhanced Raman substrate with a layered micro / nano structure can be obtained through the preparation method of this exemplary embodiment. The surface-enhanced Raman substrate is composed of a semiconductor substrate with a micropit array and a silver thin film with a thickness of 40-300 nm deposited on the micropit array of the semiconductor substrate, wherein the micropit array is formed by nanosecond It is formed by irradiating a semiconductor substrate with laser pulses up to femtoseconds, the diameter of each micro-pit in the micro-pit array is 10-20 μm, and the distance between the outer edges of any two adjacent micro-pits does not exceed the diameter 1 / 6, the micropit array has a plurality of nano-protrusion points with a particle diameter of 40-90nm.

[0041]Further, the diameter of each micropit in the micropit array is 13-17 μm, and the distance between the outer edges of any two adjacent micropits is from zero to 1 / 10 of the diameter, and the nano-p...

example 1

[0044] The substrate is n-type single crystal silicon with a resistivity of 1-5Ω·cm. The sample was irradiated with a femtosecond laser system that generated laser pulses with a center wavelength of 800 nm, a pulse width of 104 fs, and a repetition rate of 1 kHz. Use a power of 5 mW to focus the laser beam perpendicular to the surface of these samples. The laser pulse is Gaussian, with a spot diameter of 14 μm at the focal plane. The high-speed inching of the laser is precisely controlled by the scanning galvanometer suitable for the laser system to generate a 5×5mm dot matrix on the Si substrate. The number of pulses per point can be selected between 8 and 40.

[0045] Next, the substrate was ultrasonically cleaned with ethanol and ultrapure water for 10 minutes, respectively. Afterwards, the samples were dried in a vacuum oven at 100 °C for 20 min.

[0046] Subsequently, Ag films with thicknesses of 50.1 nm, 92.7 nm, 161.6 nm, 225.5 nm, and 282.9 nm were deposited on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com