Method for preparing graphene base membrane product

A technology of olefin-based film and graphene, which is applied in the field of graphene, can solve the problems of insufficient thermal conductivity and limited cooling range, and achieve the effect of increased density, increased density, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

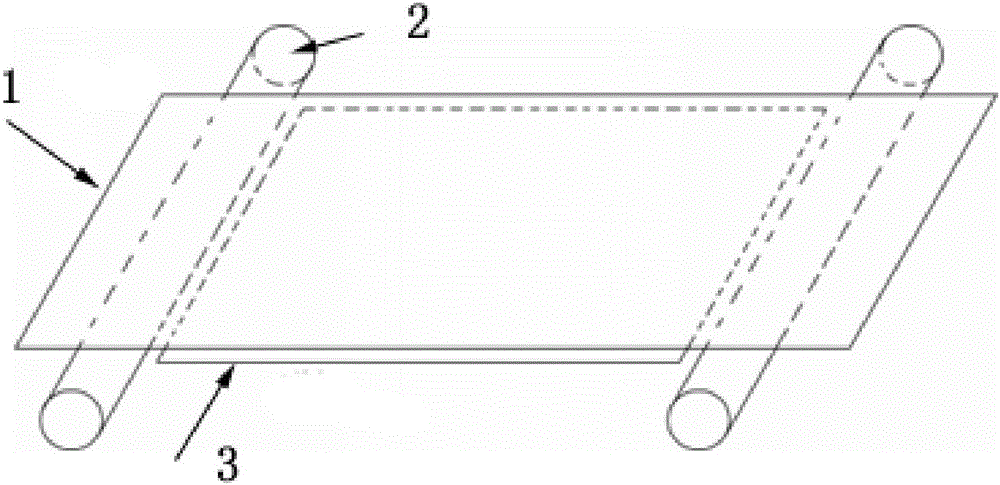

[0032] A preparation method for a graphene-based film product, comprising the following steps:

[0033] (1) Preparation of slurry: Add water-soluble graphene with a mass ratio of 30:200:40, thermal conductivity additives and bonding additives in a ball milling tank with a weight of 0.5 kg of ball milling beads in advance, and then dropwise add The binder is then added with a solvent for ball milling. The ball milling time is 1 hour. After ball milling, the slurry is taken out and stirred to remove air bubbles. The stirring speed is 100 rpm for 12 hours. Wherein, the mass ratio of ball milling beads with different particle sizes is: 1mm particle size ball milling beads: 5mm particle size ball milling beads: 10mm particle size ball milling beads = 1: 1: 1; the heat conduction aid is nano ceramic particles; the bonding The auxiliary agent is cellulose; the binder is polyurethane resin; the solvent is water; according to mass ratio, binder: bonding aid=1:3; according to mass-volum...

Embodiment 2

[0036] A preparation method for a graphene-based film product, comprising the following steps:

[0037] (1) Preparation of slurry: Add water-soluble graphene with a mass ratio of 60:500:120, thermal conductivity additives and bonding additives in a ball milling tank with a weight of 5 kg of ball milling beads, and then add viscose Then add a solvent and perform ball milling. The ball milling time is 36h. After the ball milling, take out the slurry and stir to remove air bubbles. It is ready for use. The stirring speed is 3000rpm and the time is 0.1h. Wherein, the mass ratio of ball milling beads with different particle sizes is: 1mm particle size ball milling beads: 5mm particle size ball milling beads: 10mm particle size ball milling beads = 20: 10: 8; the heat conduction aid is nano-zinc oxide; The auxiliary agent is polyvinyl alcohol; the binder is styrene-butadiene resin; the solvent is ethanol; according to mass ratio, binder: bonding aid=10:80; according to mass-volume r...

Embodiment 3

[0040] A preparation method for a graphene-based film product, comprising the following steps:

[0041] (1) Preparation of slurry: Add water-soluble graphene with a mass ratio of 50:300:100, heat conduction aid and bonding aid in a ball milling tank with a weight of 4 kg in advance, and then add viscose Then add solvent and perform ball milling. The ball milling time is 18 hours. After the ball milling, the slurry is taken out and stirred to remove air bubbles. The stirring speed is 2000rpm and the time is 6 hours. Wherein, the mass ratio of ball milling beads with different particle sizes is: 1mm particle size ball milling beads: 5mm particle size ball milling beads: 10mm particle size ball milling beads = 10: 5: 4; the heat conduction aid is carbon black; the bonding aid The agent is fumed silica; the binder is styrene-butadiene resin; the solvent is a polyhydric alcohol; according to mass ratio, binder: bonding aid=5: 40; according to mass-volume ratio, the mass of graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com