Threaded removable heater for a hot runner nozzle

A heater and nozzle technology, applied in the field of detachable heaters, can solve problems such as low heat conduction efficiency, and achieve the effects of efficient heat conduction, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

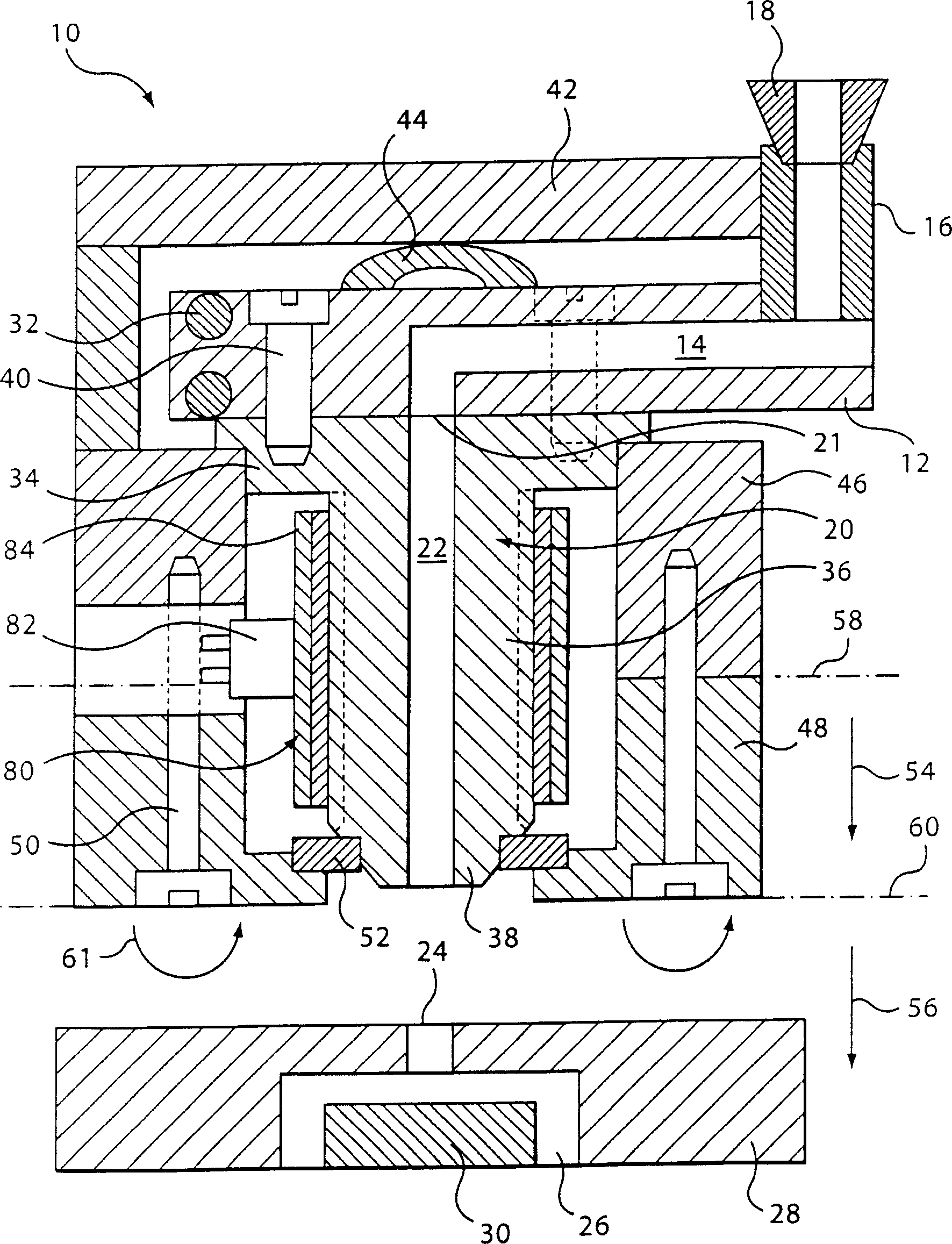

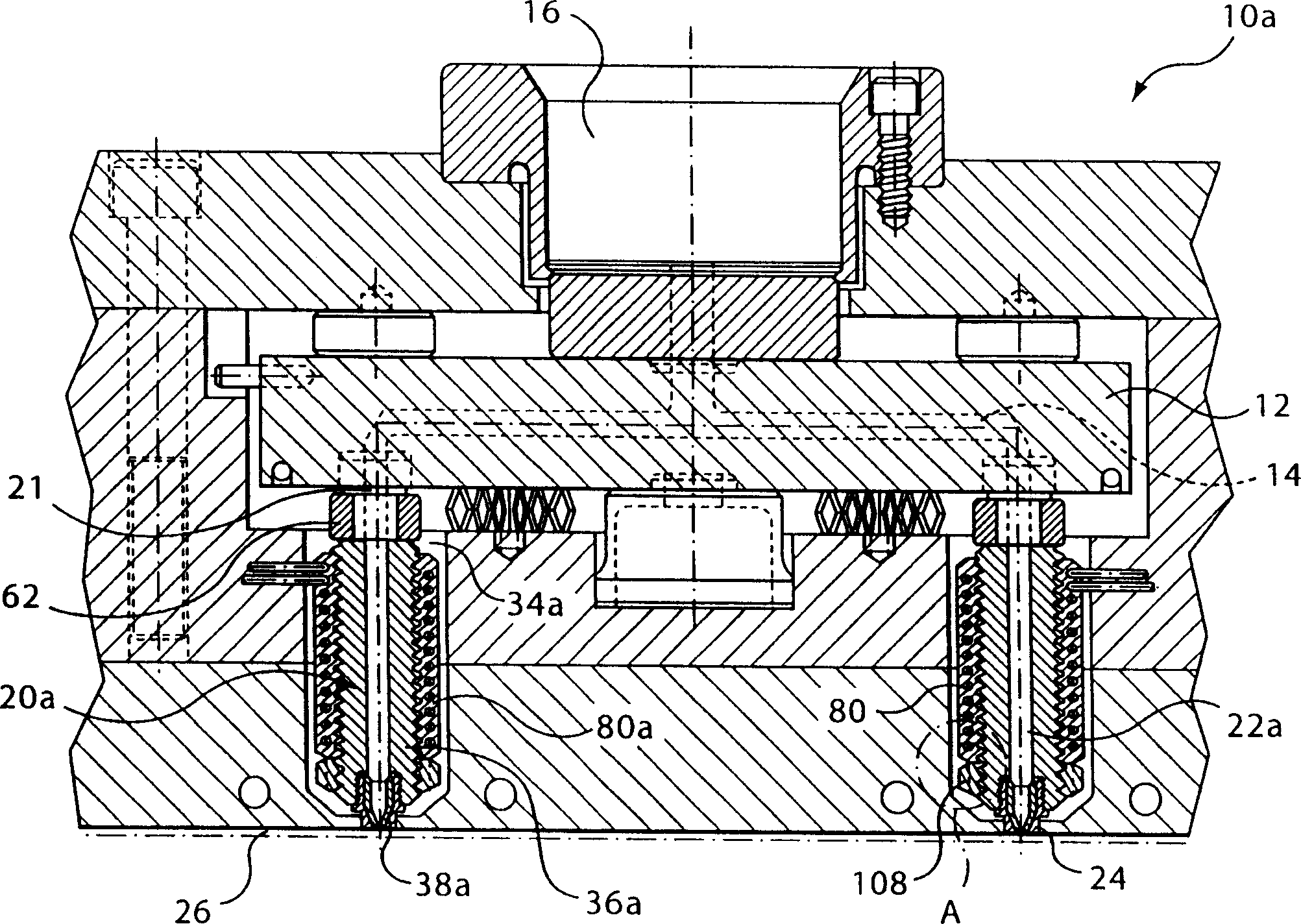

[0078] see now figure 2 , an injection molding device according to an embodiment of the present invention is represented by reference numeral 10 . The injection molding apparatus 10 includes a manifold 12 having a manifold flow path 14 for receiving pressurized plastic melt fluid from a manifold sleeve 16 . The manifold sleeve 16 extends between a support plate 42 and the manifold 12 and communicates with a machine nozzle 18 . Between the support plate 42 and the manifold 12 there is a spacer 44 . To compensate for thermal expansion of the injection molding device 10, the spacer 44 is generally flexible.

[0079] The hot runner nozzle 20 is connected to an outlet 21 of the manifold 12 . Nozzle runners 22 extend through each nozzle 20 to receive plastic melt fluid from the manifold 12 . A mold gate 24 is disposed adjacent the end of each nozzle 20 . The plastic molten fluid is controlled through the mold gate 24 to allow delivery of the molten fluid to the mold cavity 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com