Temperature equalization plate and foam metal compounded radiator

A composite foam and metal foam technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of affecting the life of LEDs, increasing the weight of lamps, inconvenient installation, etc., and achieve a broad market application value, obvious Competitive advantage, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

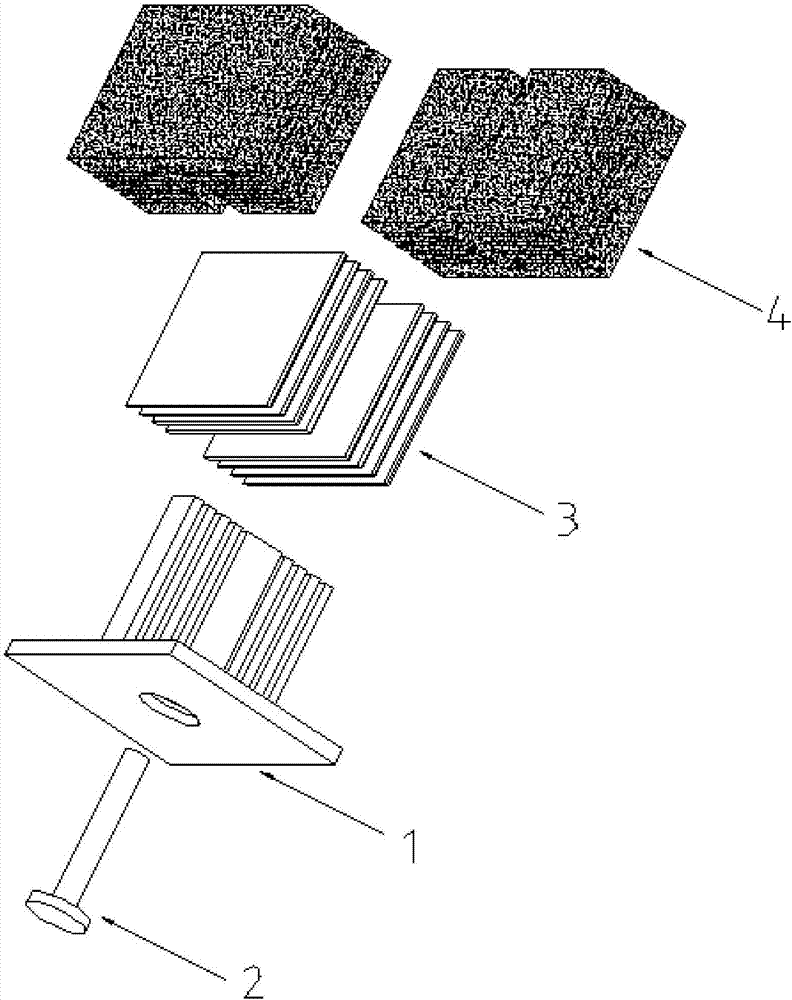

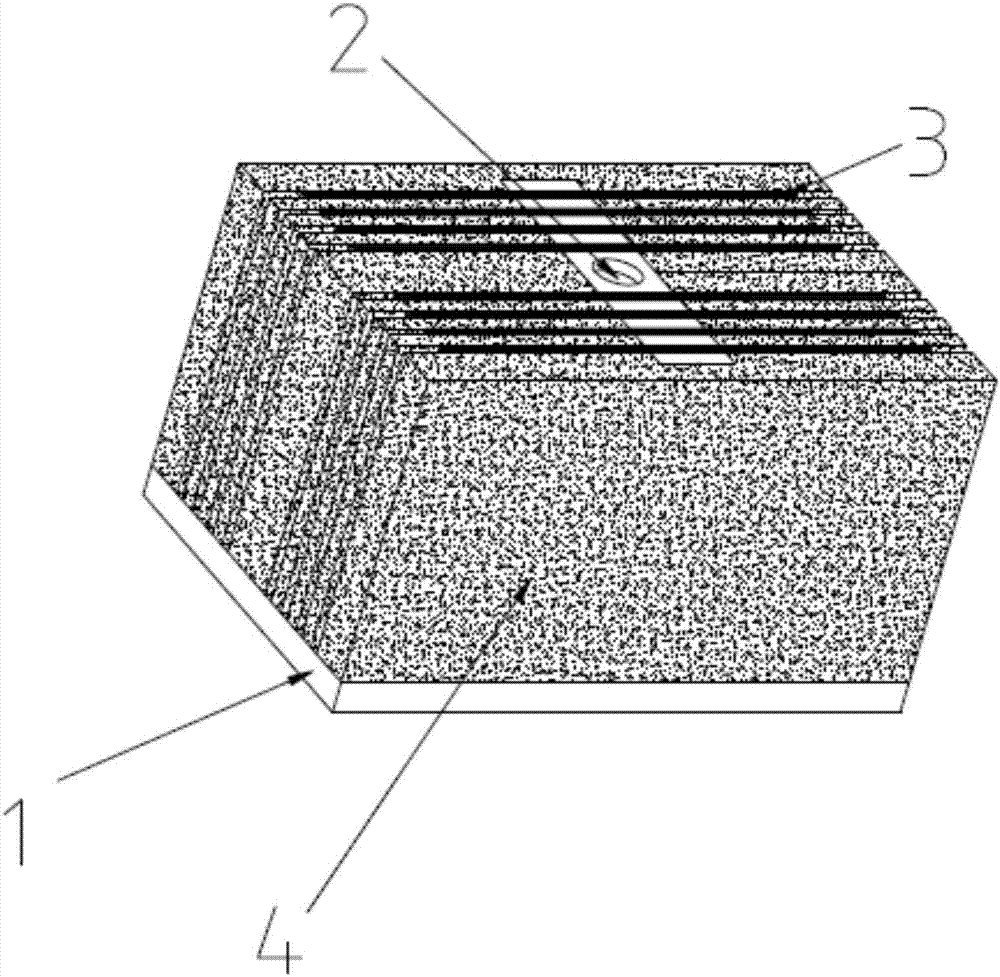

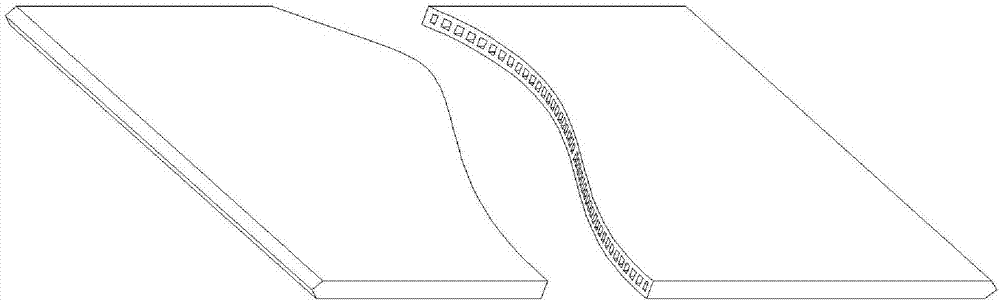

[0019] Such as Figure 1-3 As shown, a vapor chamber composite metal foam radiator includes an aluminum base plate 1, a copper column heat pipe 2, a vapor chamber 3 and a metal foam 4. The aluminum base plate 1 is integrated by a forging process, and the surface is nickel-plated for easy welding. , a through hole is opened inside, and a copper column heat pipe 2 is embedded, and the copper column heat pipe 2 is a vacuum cavity, and there is a capillary net inside and filled with liquid. The embedding method is welding; the vapor chamber 3 is a copper vapor chamber, and inside the vapor chamber 3 there are several independently parallel and equidistant microcapillary tubes that operate independently. The aluminum bottom plate 1 and the vapor chamber 3 are welded into one body; the vapor chambers 3 are uniformly arranged in the gap between the heat dissipation square co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com