Dry laminated glass production equipment and method for producing laminated glass

A technology for laminated glass and production equipment, which is applied in dry-process laminated glass production equipment and the production field of laminated glass, which can solve problems such as film suffocation, achieve the effects of reducing energy loss and facilitating rapid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment one (prior art scheme embodiment)

[0033] Glass substrate: 12mm float tempered glass (12G)

[0034] Glass size: 2.4*3.6 meters

[0035] Film: 0.76mmPVB interlayer film (two layers)

[0036] Obtained product structure: 12G / 1.52 / 12G

[0037] Roller furnace structure: Roller furnace (medium glass radiation furnace), the distance between the medium wave radiation tube and the glass surface is 150mm.

[0038] Parameter setting of the existing conventional production line:

[0039] (1) Roller furnace parameter setting:

[0040] Roller speed: 1.0 m / min;

[0041] Pressure: 6.0bar;

[0042] Pressure roller spacing: 24mm;

[0043] 1# furnace temperature: 250°C, 2# furnace temperature: 550°C.

[0044] (2) Autoclave parameter setting: heat up and pressurize for 2 hours, target temperature 130°C, pressure 1.2Mpa, hold heat for 1 hour, cool down and hold pressure for 2 hours, exhaust when the temperature reaches below 40°C, and leave the autoclave.

[0045] Proce...

Embodiment 2

[0046] Embodiment two (prior art scheme embodiment)

[0047] Glass substrate: 12mm float tempered glass (12G)

[0048] Glass size: 2.1*3.6 meters

[0049] Film: 0.76mmSGP ionic interlayer membrane (two layers)

[0050] Obtained product structure: 12G / 1.52 / 12G

[0051] Roller furnace structure: Roller furnace (medium glass radiation furnace), the distance between the medium wave radiation tube and the glass surface is 150mm.

[0052] Parameter setting of the existing conventional production line:

[0053] (1) Roller furnace parameter setting:

[0054] Roller speed: 1.1 m / min

[0055] Pressure: 6.0bar

[0056] Roller spacing: 24mm.

[0057] 1# furnace temperature: 200°C, 2# furnace temperature: 500°C.

[0058] (2) Autoclave parameter setting: heat up and pressurize for 2 hours, target temperature is 130°C, pressure is 1.2Mpa, hold heat for 2 hours, cool down and hold pressure for 2 hours, exhaust when the temperature reaches below 40°C, and leave the autoclave.

[0059] P...

Embodiment 3

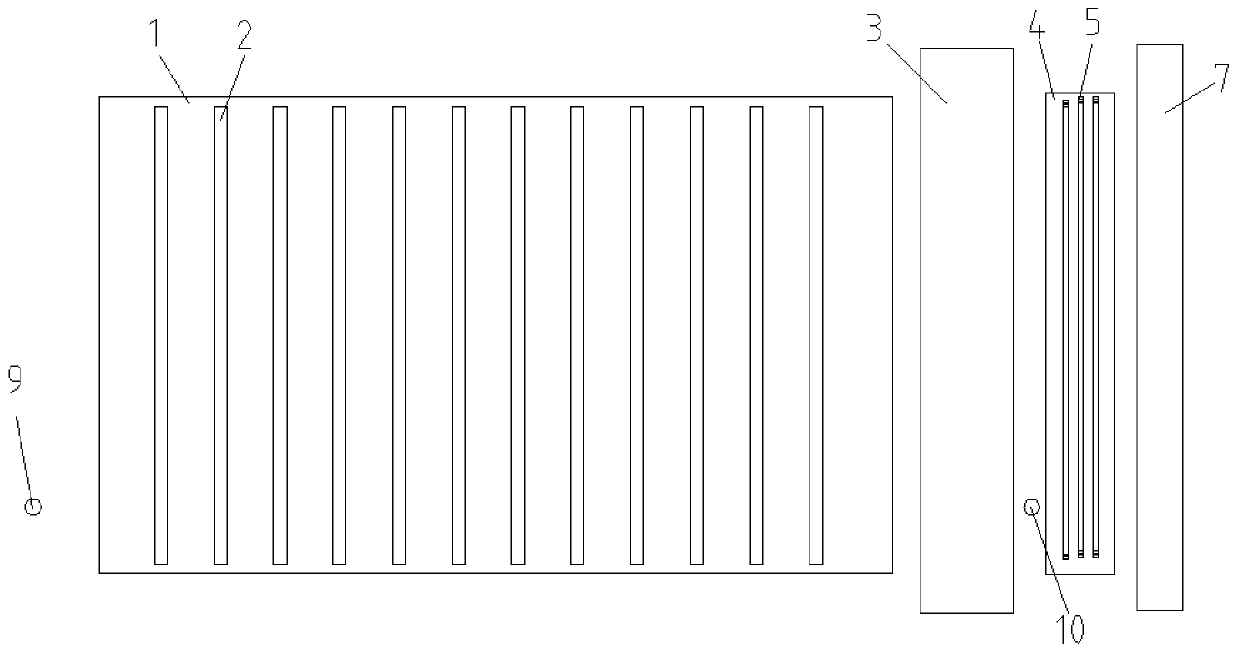

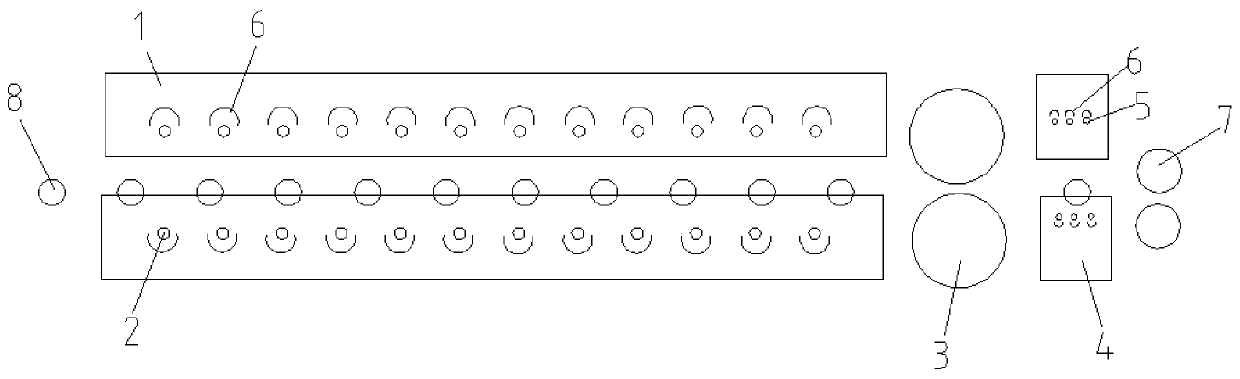

[0060] Embodiment three (the technical solution embodiment of this case)

[0061] Glass substrate: 12mm float tempered glass (12G)

[0062] Glass size: 2.4*3.6 meters

[0063] Film: 0.76mmPVB interlayer film (two layers)

[0064] Obtained product structure: 12G / 1.52 / 12G

[0065] Roller furnace structure: Roller furnace (medium glass radiation furnace), the distance between the medium wave radiation tube and the glass surface is 80mm.

[0066] (1) Roller furnace parameter setting:

[0067] Roller speed: 2.0 m / min;

[0068] Pressure: 6.0bar;

[0069] Roller spacing: 24mm.

[0070] 1# furnace temperature: 350°C, 2# furnace temperature: 700°C;

[0071] The distance between two adjacent medium-wave radiation tubes in 1# furnace and 2# furnace is 200mm.

[0072] (2) Parameter setting of edge banding compensation furnace:

[0073] The distance between two adjacent short-wave radiation tubes in the edge-banding compensation furnace is 20mm;

[0074] Edge banding compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com