Plate type heat exchanger with good sealing property

A plate heat exchanger, sealing technology, applied in the direction of heat exchanger fixing, heat exchanger sealing device, heat exchange equipment, etc., can solve the problems of small elastic deformation range, complicated processing of triangular protrusions, etc., to improve anti-blocking ability, increase rigidity, and improve compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

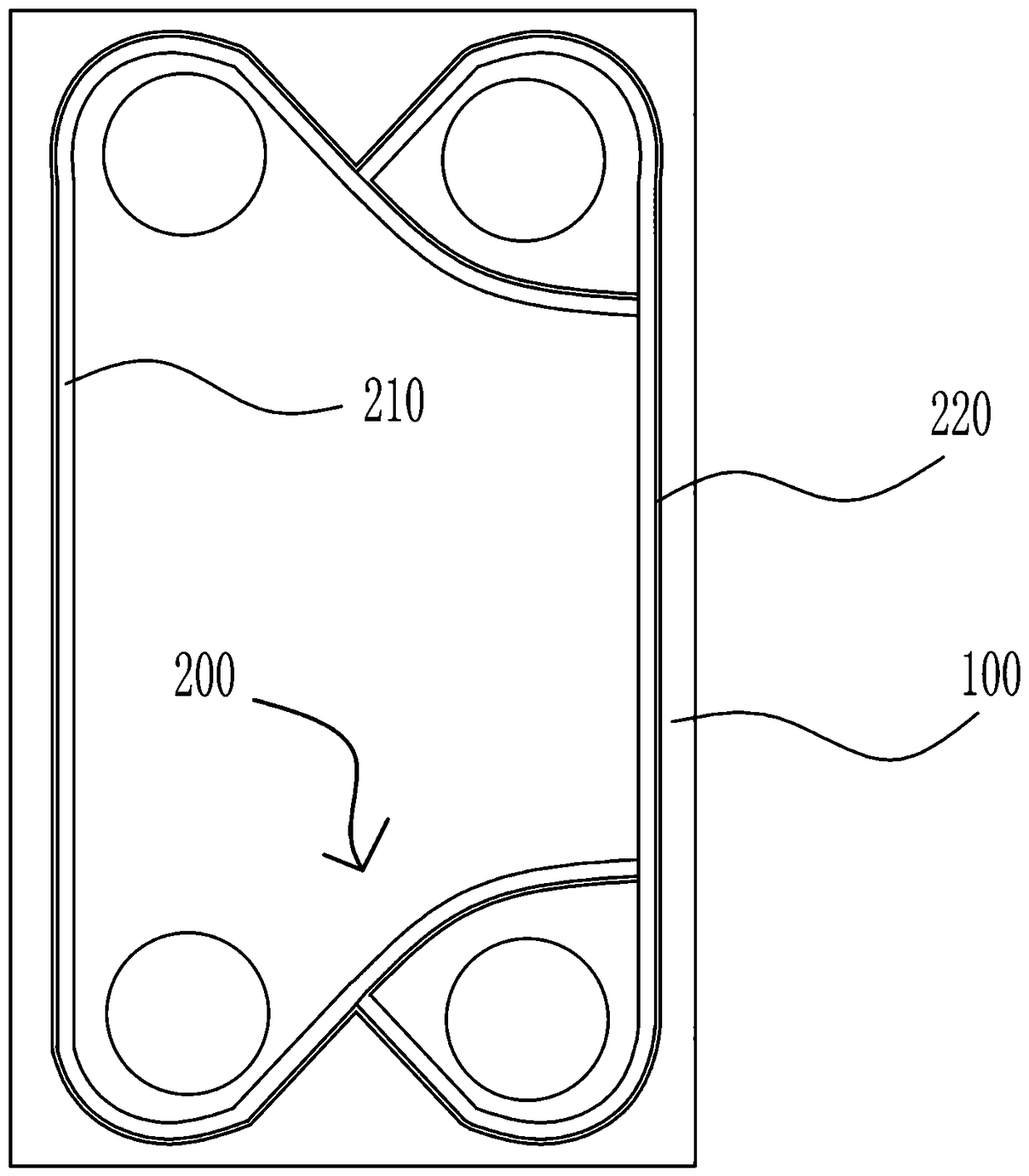

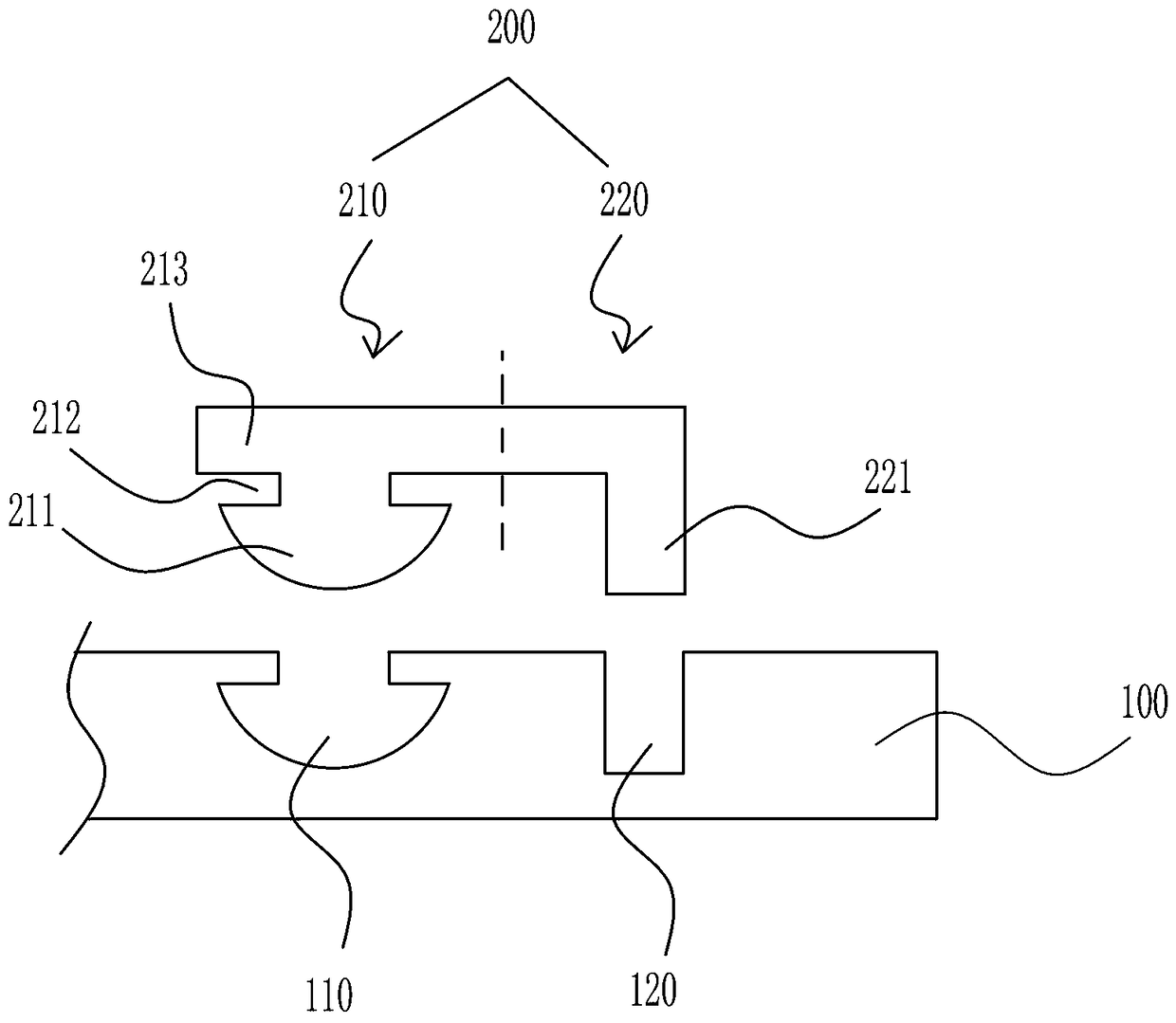

[0032] Such as figure 1 , figure 2 As shown, this embodiment provides a plate heat exchanger with good sealing performance, including a number of heat exchange plates 100 that are alternately turned over and stacked on each other and sealing gaskets 200 located between adjacent heat exchange plates 100 , the sealing gasket 200 includes a first sealing portion 210 and a second sealing portion 220 integrally formed on one side of the first sealing portion 210, the first sealing portion 210 includes an embedded arc from bottom to top Shaped bottom 211, slot part 212 and choke top 213, one side of the second sealing part 220 is in contact with one side of the choke top 213 and integrally formed, the second sealing part 220 is opposite to the The other side of the blocking top 213 is provided with a flange 221 downwards, and the heat exchange plate 100 is provided with an embedded arc-shaped groove 110 compatible with the first sealing part 210 and with the flange. The edge 221 ...

Embodiment 2

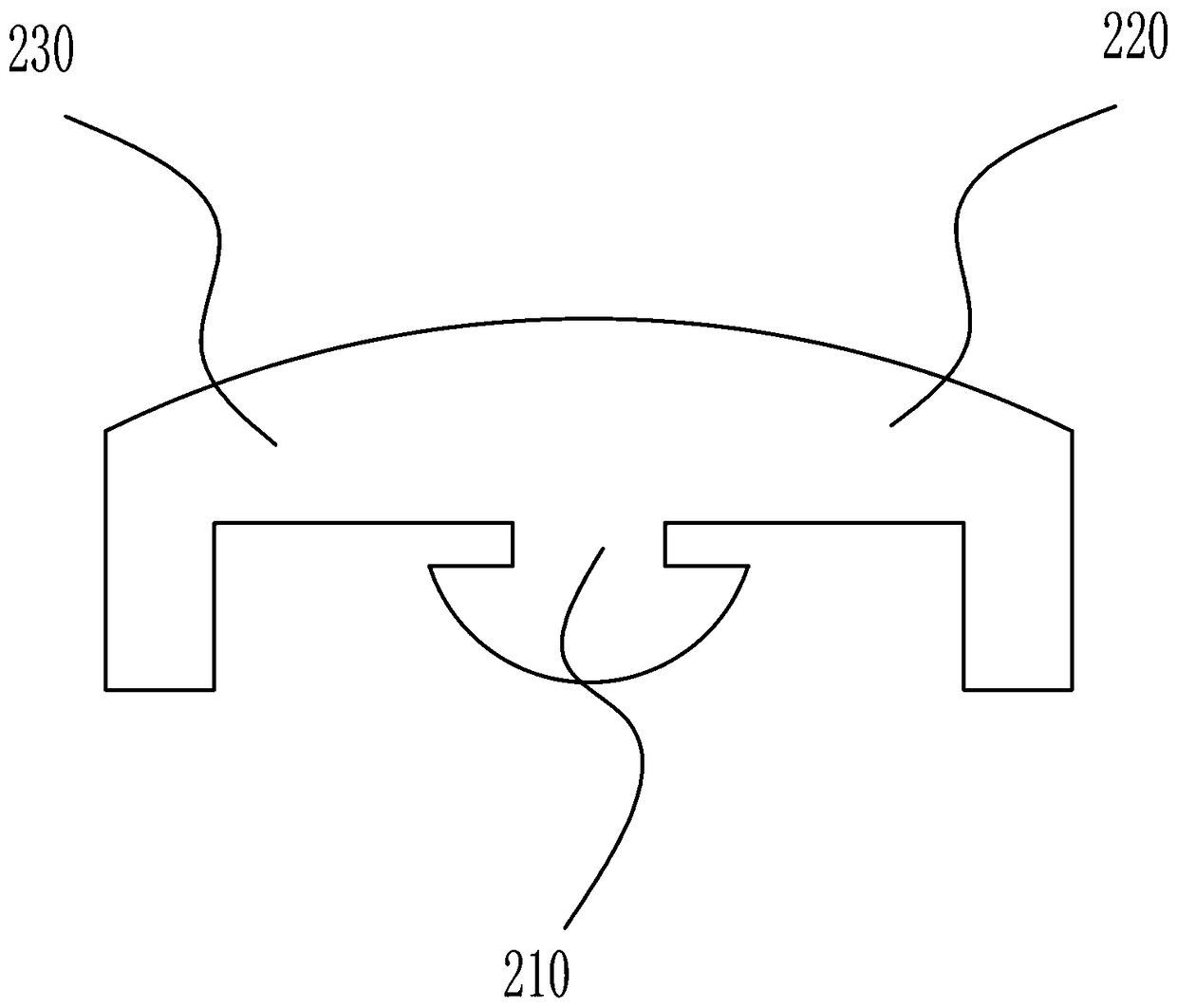

[0036] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the sealing gasket 200 further includes a third sealing portion 230 located on the side of the first sealing portion 210 and symmetrical to the second sealing portion 220 , The structure of the third sealing portion 230 is symmetrical to that of the second sealing portion 220 . The setting of the third sealing part 230 widens the sealing surface, and the sealing gasket 200 in the symmetrical arrangement state can better resist the uneven force caused by the unstable extrusion force, and reduce the possibility of the sealing gasket 200 detaching from the groove. Yes, in this embodiment, the top of the second sealing part 220 and the first sealing part 210 can be arranged to meet in an arc as shown in the figure, the third sealing part 230 is symmetrical to the second sealing part 220, and the heat exchange plates 100 is provided with a groove matching with the third sealing part 2...

Embodiment 3

[0042] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the inside of the first sealing portion 210 is hollow, and the groove portion 212 is provided with an air outlet hole 2121 communicating with the hollow structure of the first sealing portion 210 . The interior of the first sealing part 210 is set to be hollow, and the top surface of the blocking top 213 is an arc surface and the arc surface of the embedded arc bottom 211 is conducive to further increasing the elastic deformation range of the first sealing part 210, making it There is a larger deformation space when under pressure, thereby improving the problem of uneven stress on the sealing gasket 200 during compression assembly, and helping to avoid the problem of extravasation of individual parts caused by the inconsistent deformation of the sealing gasket 200 as much as possible.

[0043] The heat exchange plate 100 and the sealing gasket 200 are connected together by a fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com