Boiler energy-saving device, and method and tool for manufacturing S-shaped fin heat exchange tube of boiler energy-saving device

A technology of heat exchange tubes and economizers, which is applied in the field of energy-saving devices, can solve the problems of high production cost, low production efficiency, and a large number of welded joints, and achieve the effects of reducing manufacturing costs, improving production efficiency, and efficient heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

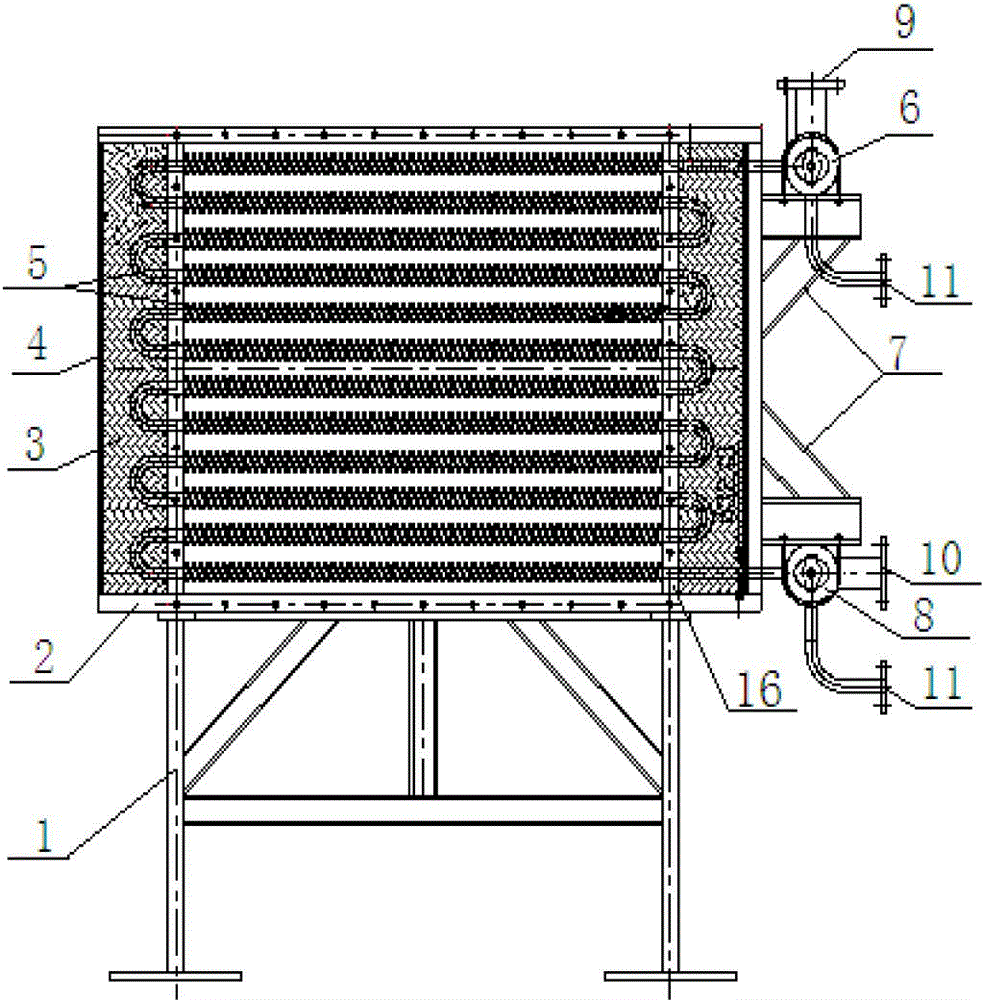

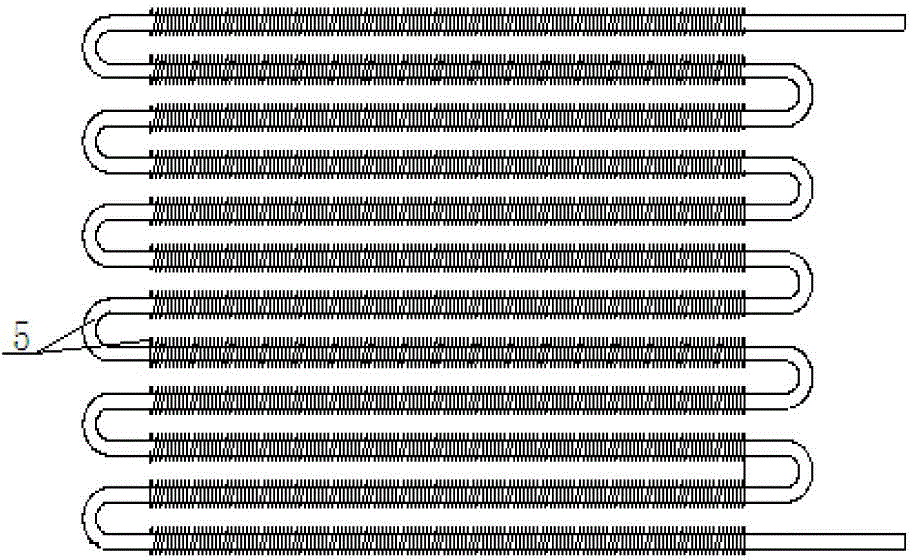

[0044]The invention is a boiler economizer, which is arranged on the boiler flue, adopts 20# steel (namely No. Structural steel, yield strength 195Mpa, specification: 1.5X15mm, the spiral fins in this embodiment are all of this specification), high-density (pitch t≤5.66mm) finned tubes (that is, spiral fins welded by high-frequency resistance Serpentine fin group and serpentine heat exchange tube) are heat conduction elements, which conduct convective heat exchange between the high-temperature waste heat flue gas of the boiler and the fresh cold air or water entering the boiler, so as to achieve the effects of waste heat utilization, energy saving and emission reduction.

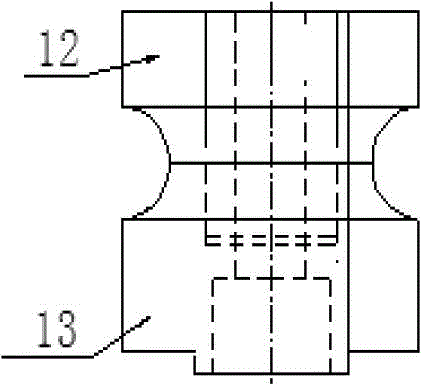

[0045] see figure 1 , figure 2 As shown: the structure of the energy saver of the present invention includes a box body 2 arranged on a bracket 1, and a serpentine heat exchange tube is arranged inside the box body 2, and both ends of the serpentine heat exchange tube are fixed on the box body by splints 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com