High-power LED (light-emitting diode) light source packaging structure manufactured by graphene and production process thereof

A technology of LED light source and packaging structure, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of easy promotion and application, efficient heat conduction, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the advantages and technical solutions of the present invention more clear, further descriptions will be made below in conjunction with the accompanying drawings.

[0027] refer to figure 1 , figure 2 , image 3 , using graphene as the LED light source substrate and chip carrying area material to make a 50W LED light source.

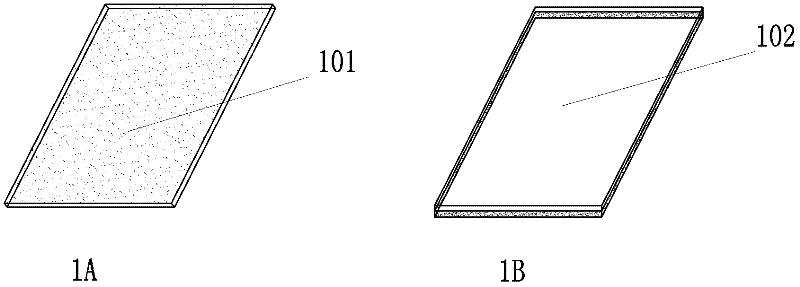

[0028] The LED light source is composed of three parts: a light source substrate 12 , a surrounding frame 11 , and a chip carrying area 10 . The chip carrying area can directly use the surface-treated sheet-shaped graphene carrying sheet 101 , or use copper-based graphene 102 .

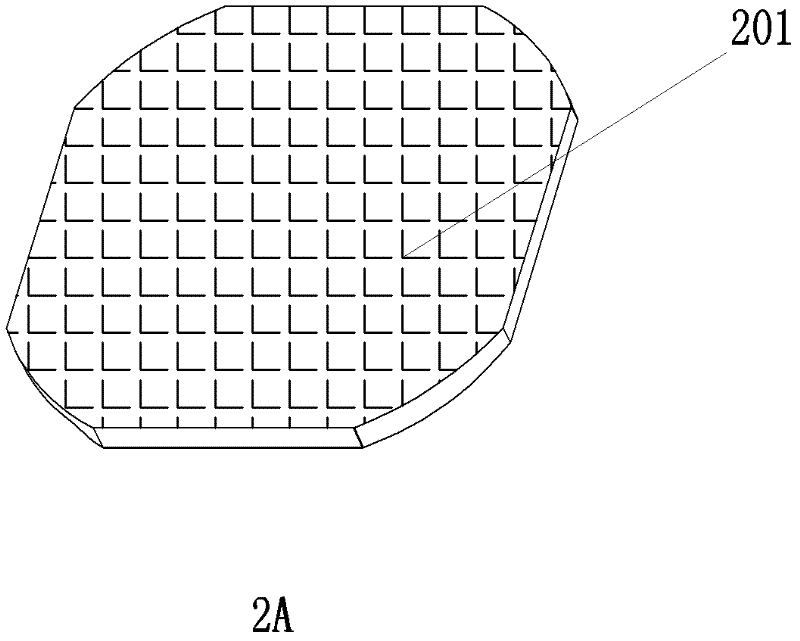

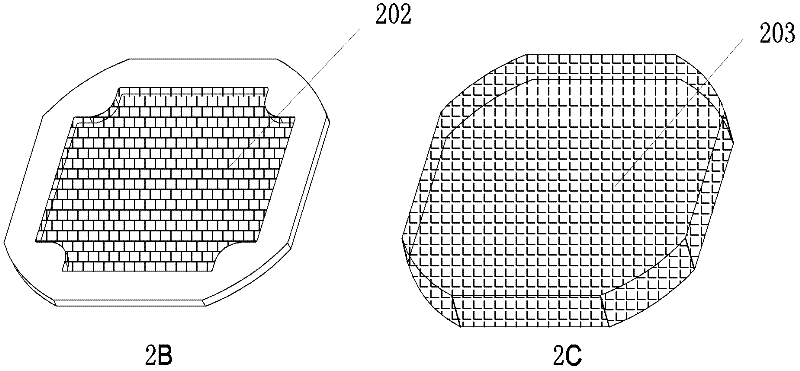

[0029] Such as Figure 2A and figure 2 B. figure 2 As shown in C, the light source substrate adopts the light source substrate 201 that conforms to the shape requirements by covering and bonding graphene on the surface of other easy-to-form flame-retardant materials by means of spraying, electroplating, vacuum coating or vacuum sputtering.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com