Conduction oil internal circulation type heating roller

A technology of heat conduction oil and heating rollers, which is applied in the field of heating rollers, can solve the problems of high energy consumption and poor heating effect, achieve high heat conduction, improve service life, and prevent excessive centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Such as figure 1 As shown, the heat transfer oil internal circulation heating roller includes an outer cylinder body 1, end plates 3 welded and closed at both ends of the outer cylinder body, and left and right support shafts 5 located at both ends of the outer cylinder body.

[0023] Such as figure 1 As shown, an inner cylinder 2 coaxial with the outer cylinder is provided inside the outer cylinder 1, the two ends of the inner cylinder 2 are welded to the end plates, and a heat transfer oil chamber 8 is formed between the outer cylinder and the inner cylinder. The heat-conducting oil chamber 8 is filled with heat-conducting oil.

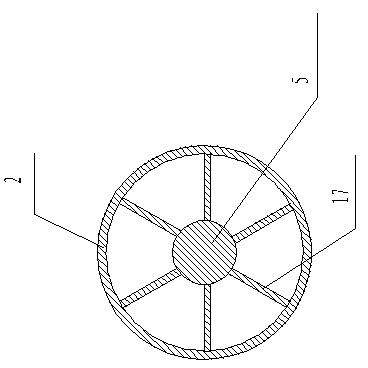

[0024] Such as figure 1 As shown, the left and right support shafts 5 respectively pass through the end discs 3 at both ends of the outer cylinder and penetrate into the inner cylinder. In order to strengthen the connection strength between the support shaft 5 and the end disc 3, a support shaft is provided inside the inner cylinder 2. Rib...

Embodiment 2

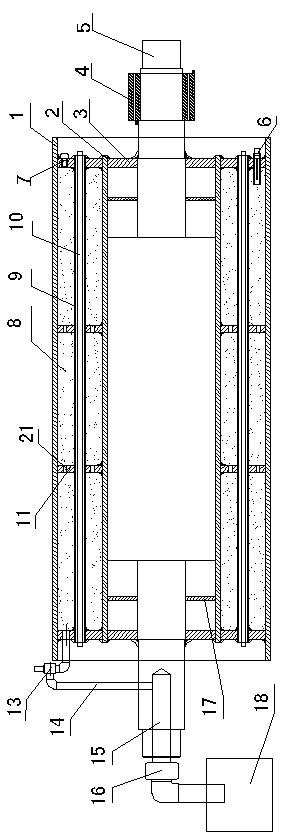

[0035] Such as figure 2 As shown, the heating roller provided in this embodiment includes an outer cylinder body 1 , end plates 3 welded and closed at both ends of the outer cylinder body, and left and right support shafts 5 located at both ends of the outer cylinder body.

[0036] Such as figure 2 As shown, in this embodiment, the heating roller is also provided with a heat transfer oil injection hole, an oil discharge pipe, a safety valve, and a thermocouple, and its design and arrangement are the same as in Embodiment 1, except for the heating device in the heat transfer oil chamber.

[0037] Such as figure 2 As shown, the heating device in this embodiment is that the outer surface of the inner cylinder 2 is circumferentially provided with a plurality of tubes 9 coaxial with the inner tube, and the tubes 9 extend toward both ends of the inner tube and pass through Through the end disks 3 at both ends, an electric heating tube 10 is installed in the hosting 9, and t...

Embodiment 3

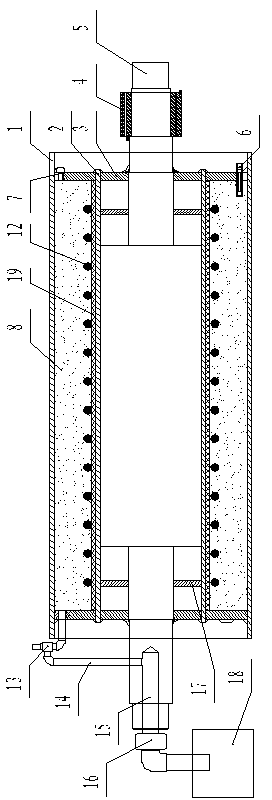

[0040] Such as image 3 As shown, the heating roller provided in this embodiment includes an outer cylinder body 1, an end plate 3 welded and closed at both ends of the outer cylinder body, left and right support shafts 5 located at both ends of the outer cylinder body, a heat transfer oil injection hole 7, an oil discharge pipe 14, The safety valve 13 and the thermocouple 6 are designed and arranged the same as the heating rollers in Embodiment 1 and Embodiment 2, and the difference also lies in the heating device in the heat-conducting oil chamber.

[0041] Such as image 3As shown, the heating device includes several hosting support rings 11 uniformly distributed along the cylinder axis in the heat transfer oil chamber, the hosting support rings 11 are sleeved on the outer surface of the inner cylinder 2, and the inside of the hosting support ring ring body and the inner cylinder The outer surface of the body 2 is fixed by welding, and the outer side of the supporting ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com