Water-cooled fixture of grinding machine

A water-cooled, grinding machine technology, used in manufacturing tools, grinding workpiece supports, grinding/polishing equipment, etc., can solve problems such as poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

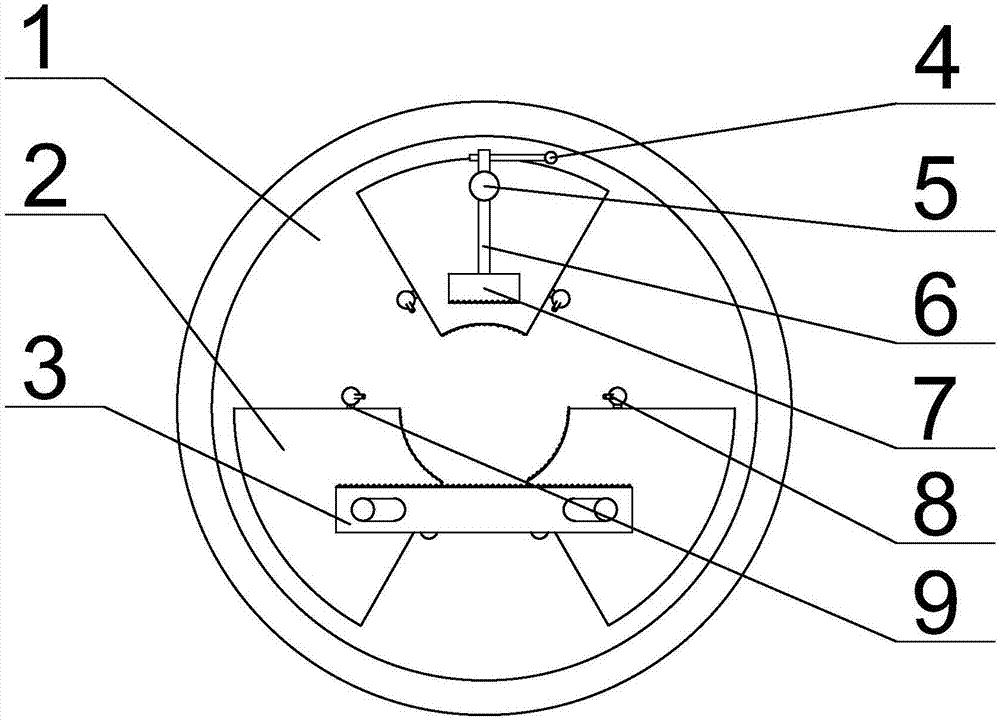

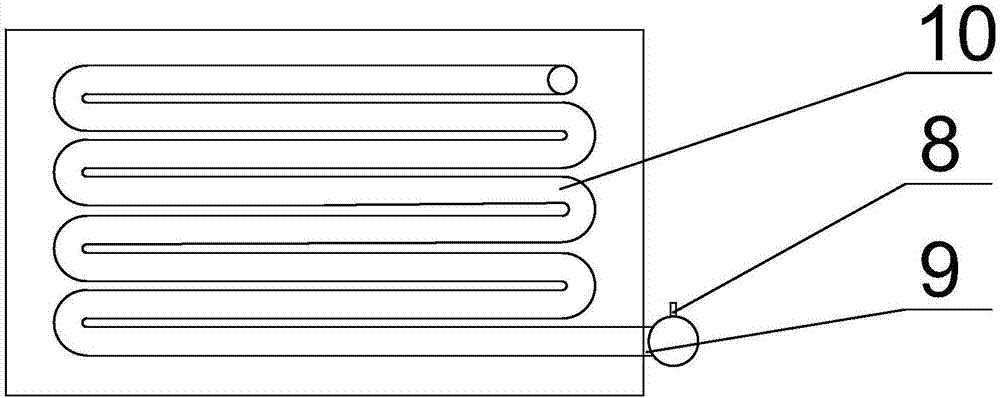

[0014] Embodiment 1: as figure 1 , as shown in 2, a water-cooled grinder fixture, including a fixture base plate, several jaws 2, a fixed block 1, a clamping block 7, a screw rod 6, a clamping column 5, a tightening arm 4 and a water cooling device, the jaws It is arranged on the upper surface of the fixture bottom plate and is slidably connected with the fixture bottom plate, the sliding connection track of the claw and the fixture bottom plate intersects at the center of the top surface of the fixture bottom plate, and the two ends of the fixed block are respectively slidably connected with the upper end surfaces of the two claws , the clamping column is arranged on the upper end surface of the claw, the screw rod passes through the clamping column and is threadedly connected with the clamping column, the clamping arm is arranged at one end of the screw rod, and the clamping block is arranged At the other end of the screw, the water cooling device includes a nozzle 8, an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com