Novel hybrid-driven energy-saving air conditioning terminal

An energy-saving air-conditioning and driving technology, applied in air-conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of inability to save energy at low temperature and inability to realize enhanced heat transfer of liquid pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

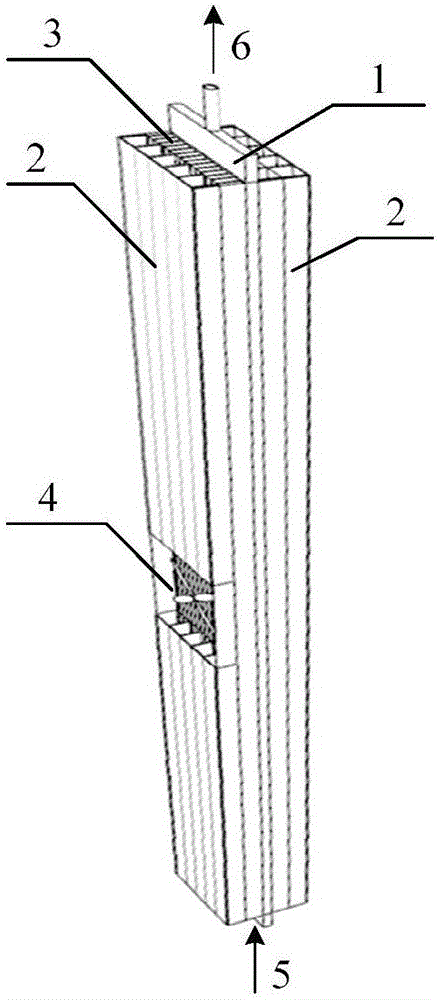

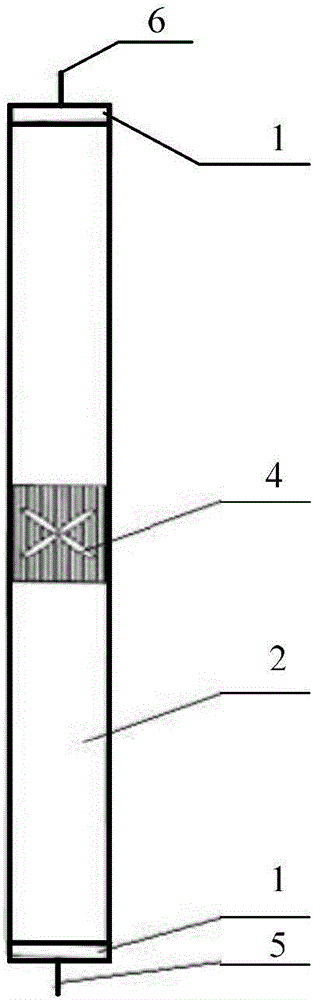

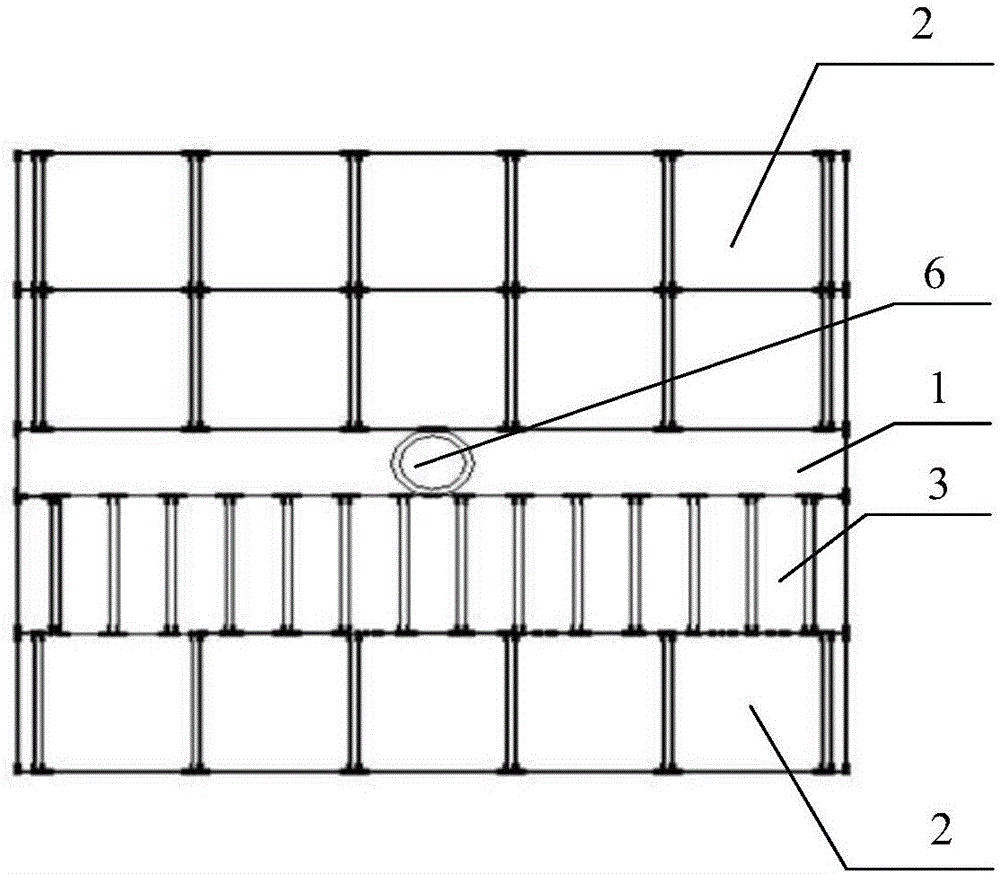

[0035] The present invention will be described below in conjunction with the accompanying drawings.

[0036] The invention relates to a new type of hybrid drive energy-saving air conditioner terminal, such as Figure 1a , 1b , the perspective view, front view and top view described in 1c, including a plate-shaped heat transport device 1 and a parallel channel fin heat exchange structure, the plate-shaped heat transport device 1 is extruded from a metal material and has two The above microtubes are arranged side by side and each microtube is a plate-shaped structure that carries out heat exchange and transmission through a flowing medium. The flow medium communicates with the air-conditioning medium or is physically separated from each other; the parallel-channel fin heat exchange structure is compounded on the plate surface of the plate-shaped heat transport device 1 and the parallel-channel fin heat exchange structure has several The air convection channels arranged side by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com