Low-temperature heating radiator

A radiator and low-temperature technology, applied to radiators, tubular elements, heat exchange equipment, etc., can solve problems such as poor adjustment ability, low heat transfer coefficient, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described below in conjunction with the accompanying drawings.

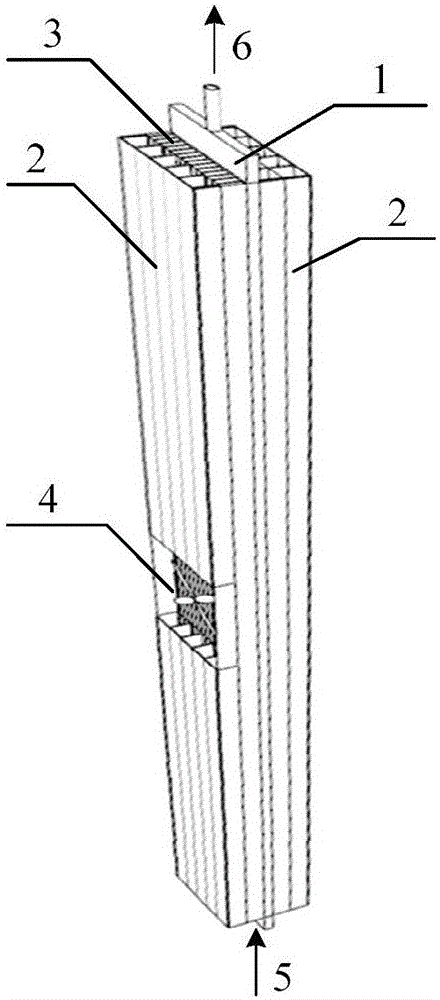

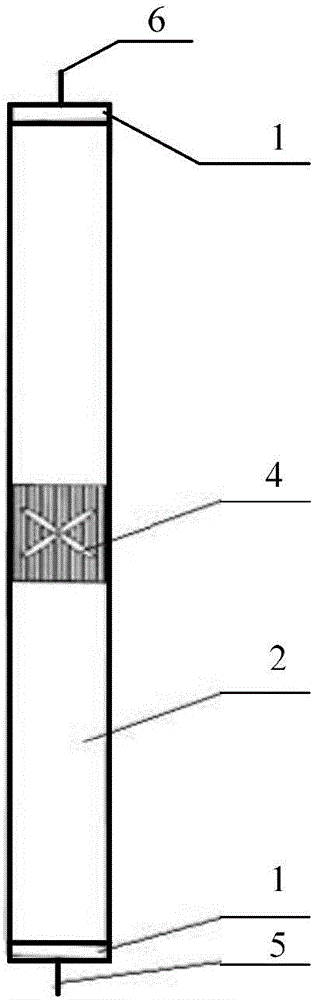

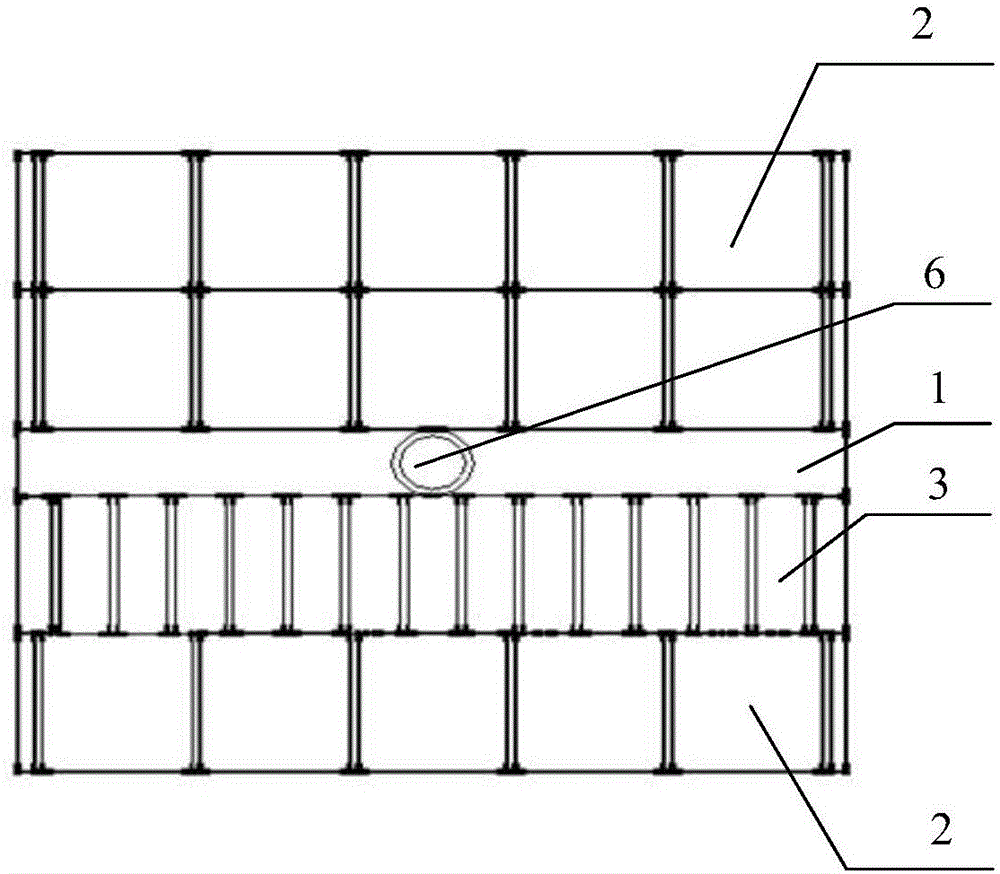

[0036] The invention relates to a low-temperature radiator, such as Figure 1a , 1b , the perspective view, front view and top view described in 1c, including a plate-shaped heat transport device 1 and a parallel channel fin heat exchange structure, the plate-shaped heat transport device 1 is extruded from a metal material and has two The above microtubes are arranged side by side and each microtube has a plate-shaped structure for heat exchange and transmission through a flowing medium. The equivalent diameter of the microtube is 3-10 mm, preferably 4-6 mm. The two ends of the plate-shaped heat transport device 1 are respectively The heating water inlet pipe 5 and the heating water outlet pipe 6 are connected, and the flow medium in each microtube communicates with or is physically isolated from the water in the heating water inlet and outlet pipes; the parallel channel fin h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com