Anti-short circuit method of lithium ion battery

A lithium-ion battery, anti-short circuit technology, applied in the direction of circuits, secondary batteries, battery pack components, etc., can solve problems such as short circuit, fire, battery easy to overlap, etc., to achieve easy operation and control, easy operation, and convenient photography recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

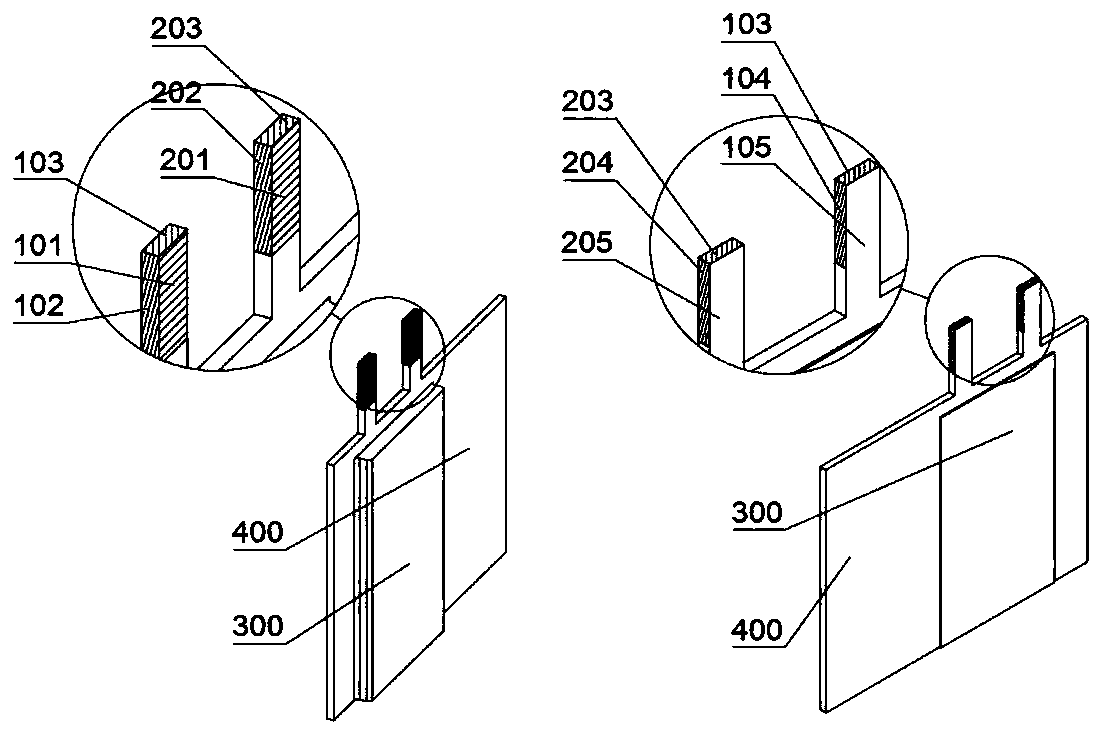

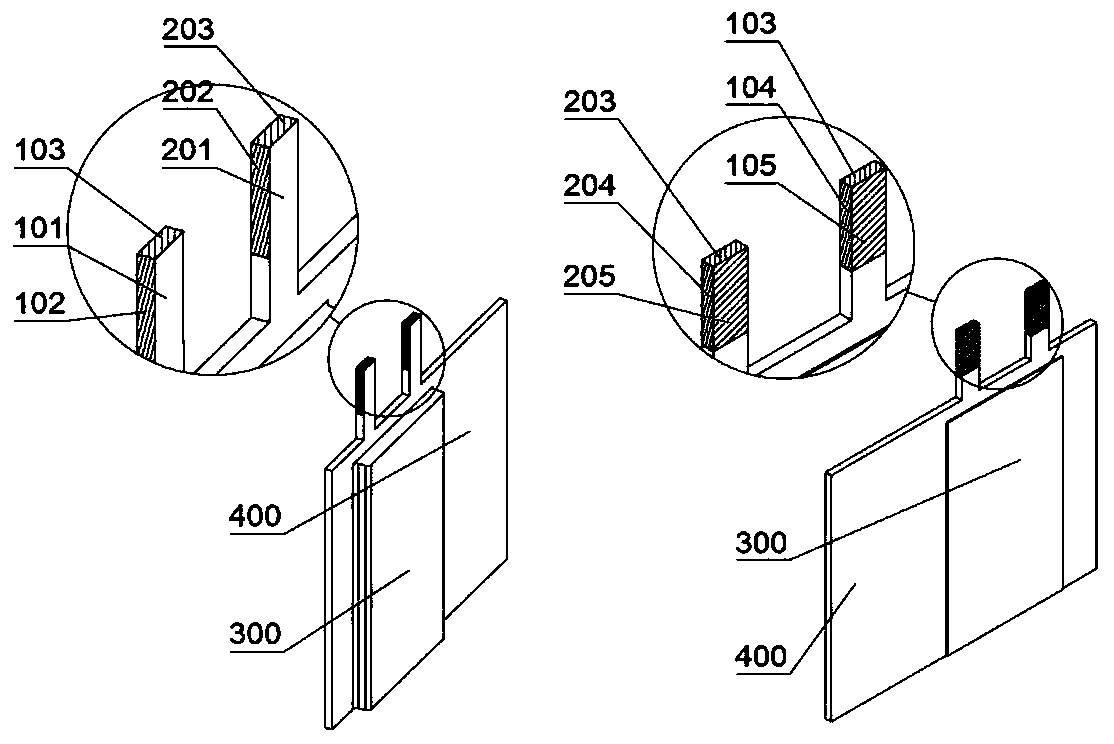

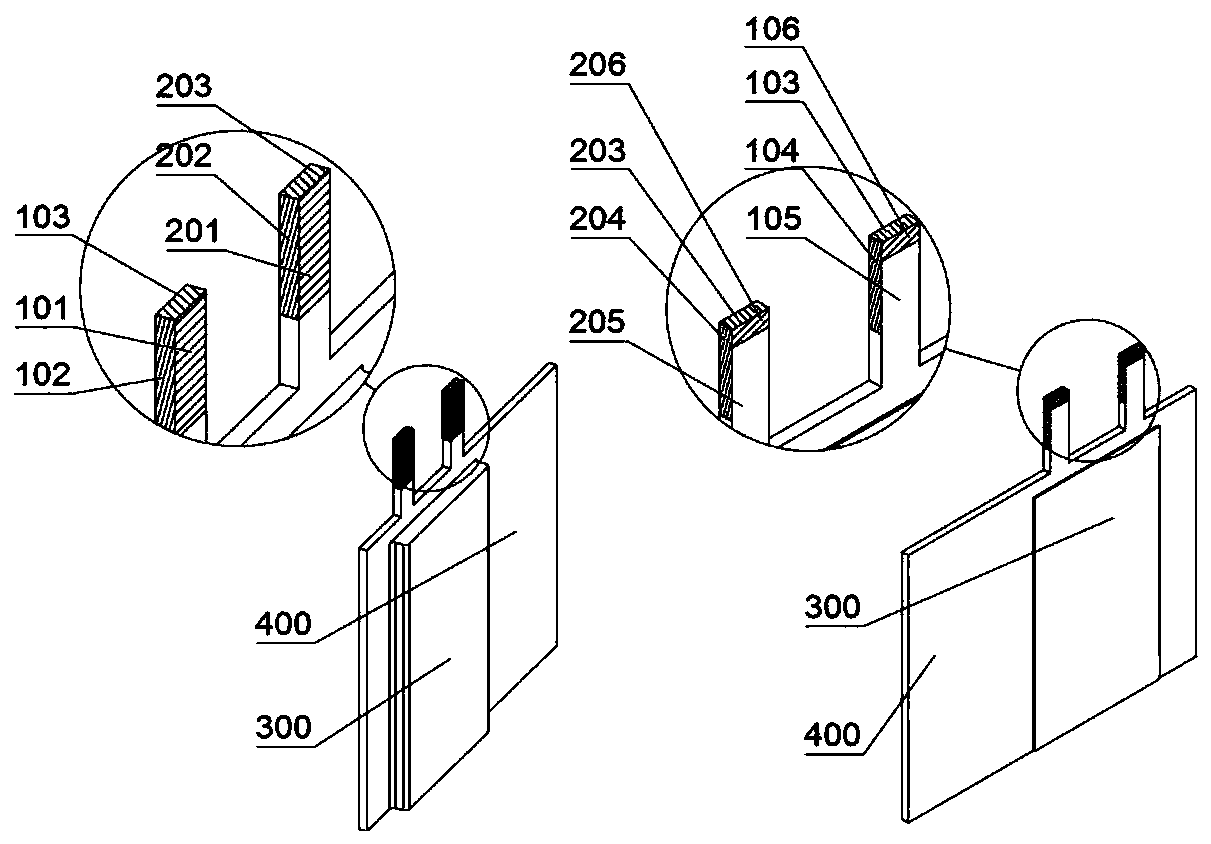

[0026] Specific Embodiment 1: This embodiment describes a short-circuit prevention method for lithium-ion batteries. The method is to cover the surface of the exposed tabs of the lithium-ion battery with insulating materials. During the production process, even if two tabs are overlapped Together, they will not be turned on to cause a short circuit of the battery, and the size and thickness of the insulating material are controlled within the process range.

specific Embodiment approach 2

[0027] Specific embodiment two: a kind of lithium-ion battery anti-short-circuit method described in specific embodiment one, described insulating material is Teflon, alumina ceramics, ceramic polymer or polytetrafluoroethylene, needs to have wear-resisting, resistant Basic properties such as high temperature, insulation, corrosion resistance, and easy operation should also have obvious color difference from the surface of tabs and batteries.

specific Embodiment approach 3

[0028] Specific embodiment three: a lithium-ion battery anti-short circuit method described in specific embodiment 1 or 2, the thickness of the insulating material is 10-20um, too thin will affect the wear resistance of the coating, and too thick will waste materials, At the same time, it will also increase the weight of the battery tab, causing the tab to bend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com