White light lens of light-emitting diode and light-emitting diode composed of lens

A technology of light-emitting diodes and lenses, which is applied to optical elements, light sources, point light sources, etc. to change the spectral characteristics of emitted light, and can solve problems such as color differences in street lamps, affecting the performance of light-emitting diodes, and color differences in light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

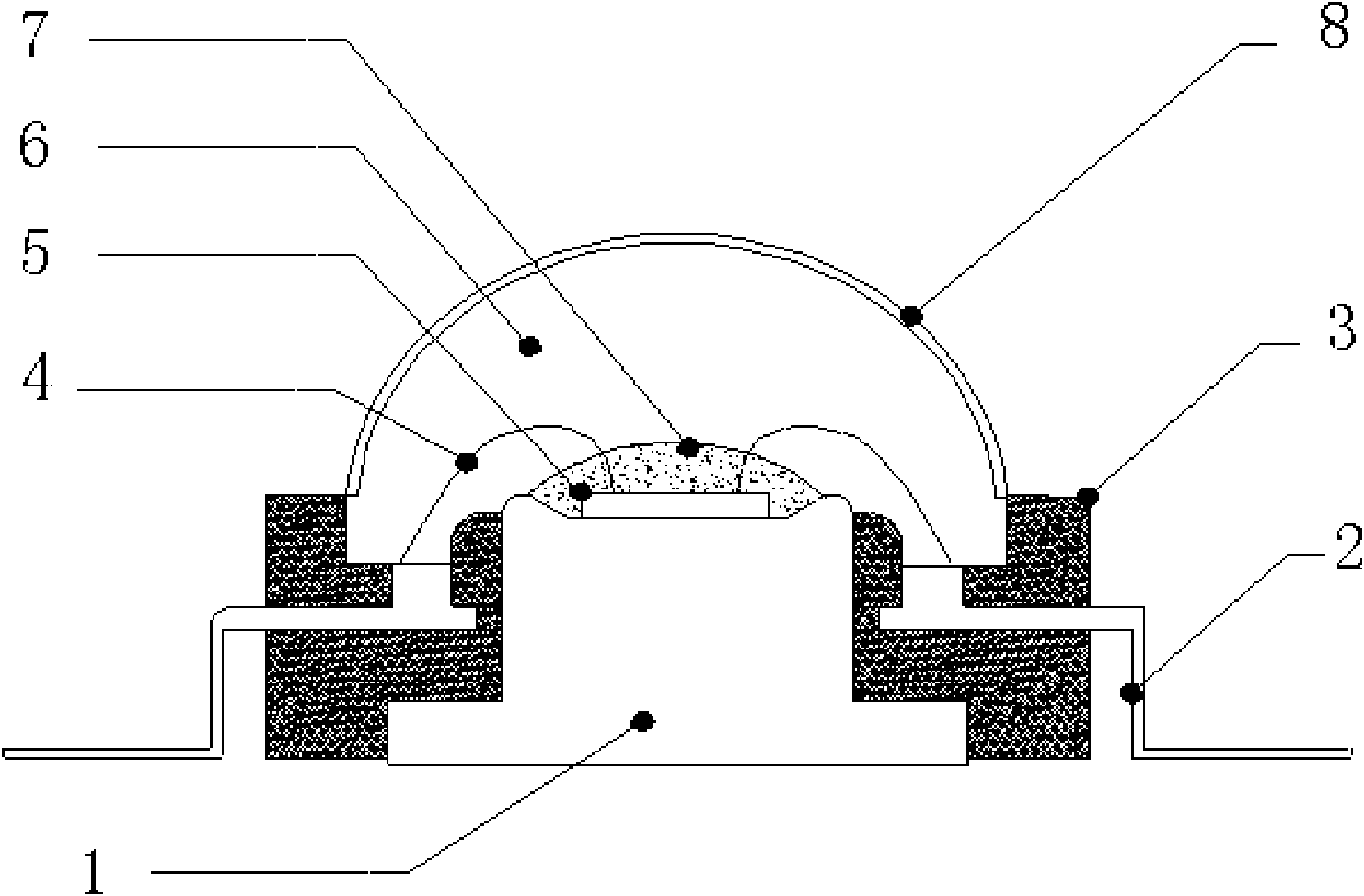

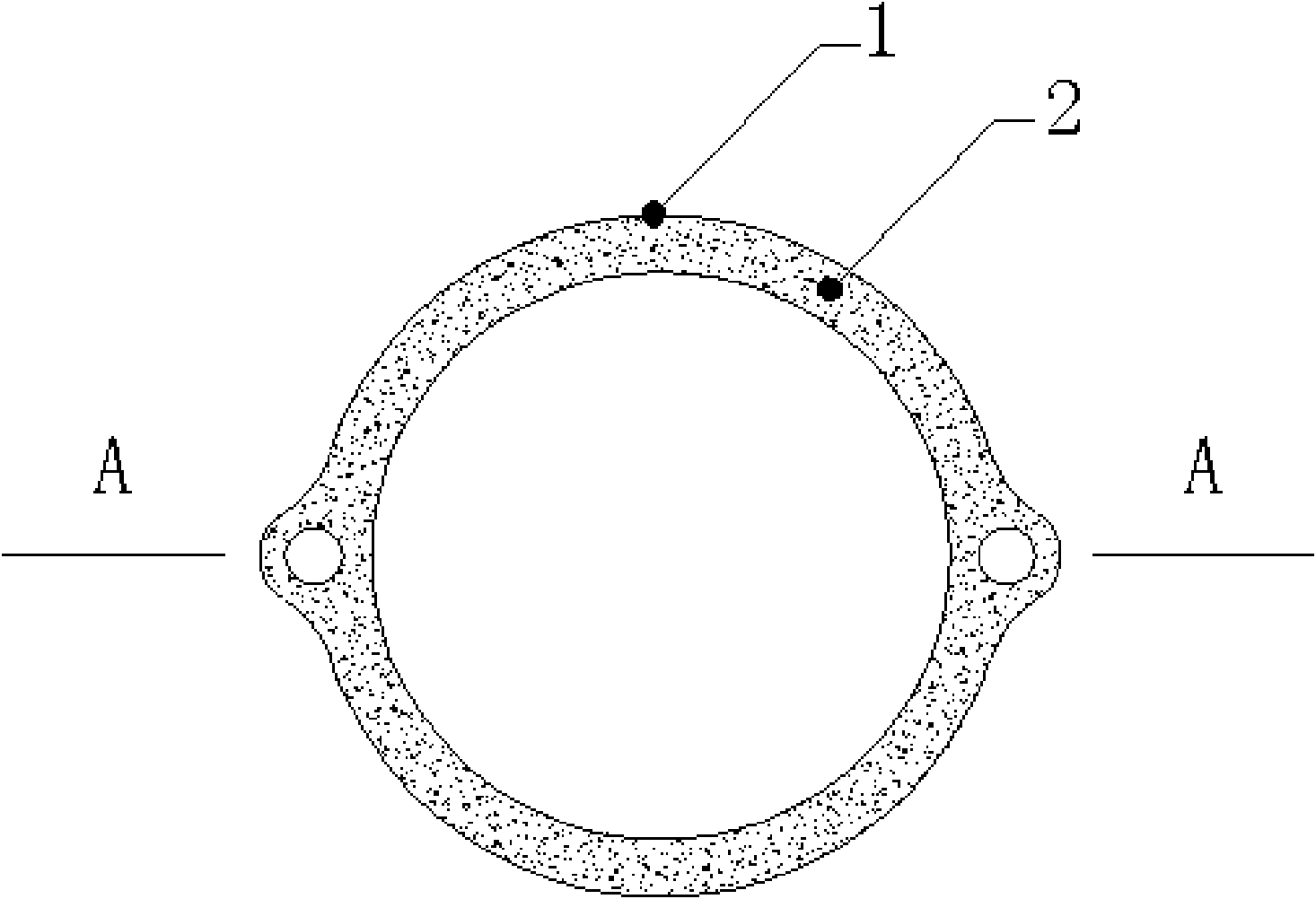

[0033] like Figure 2-4 As shown, the light-emitting diode white light lens in this embodiment is formed by lens substrate polycarbonate and phosphor powder with a wavelength of 580 nm as raw materials. The mass ratio of the lens substrate to phosphor powder is polycarbonate: Phosphor powder = 5:1. The light-emitting diode white light lens of this embodiment is mixed with polycarbonate and fluorescent powder in the above ratio, and injected at a temperature of about 50°C to form a lens with a semicircular cross-section. Two small holes are symmetrically arranged on the edge of the lens. , when the filled silica gel 6 is injected, part of the filled silica gel 6 overflows from the small hole, and the connection between the lens 7 and the bracket 3 can be made more stable after curing.

[0034] The light-emitting diode composed of the lens of this embodiment is mainly composed of a chip 5, a heat-conducting copper column 1, an electrode line 2, a bracket 3, a gold wire 4, a len...

Embodiment 2

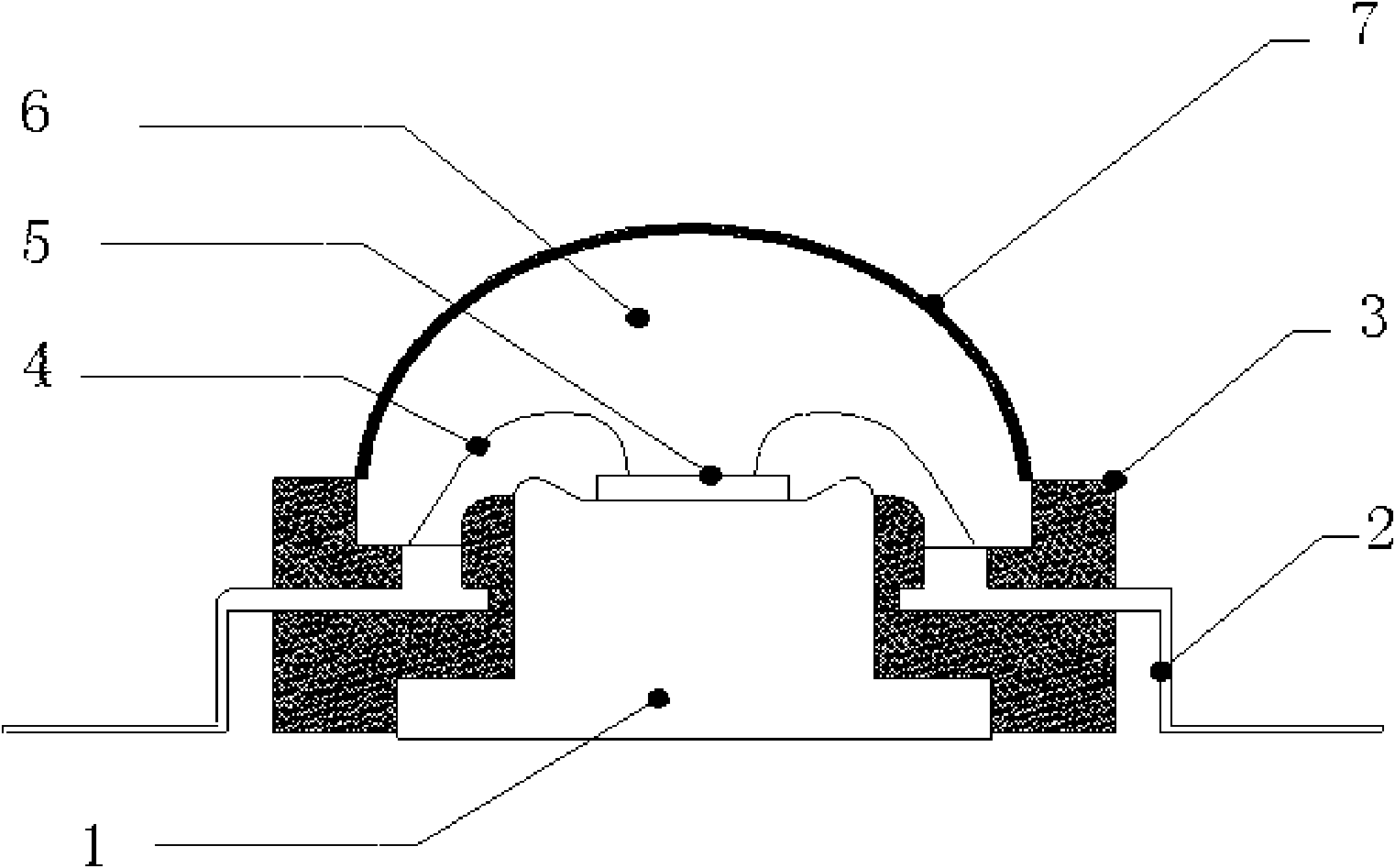

[0036] like Figure 2-4As shown, the light-emitting diode white light lens in this embodiment is made of lens substrate silica gel and phosphor powder with a wavelength of 580 nm as raw materials. The mass ratio of the lens substrate to phosphor powder is silica gel: phosphor powder=500 : 1. The light-emitting diode white light lens of this embodiment is formed by injection molding at a temperature of about 200° C. to form a semicircular cross-section after mixing the above-mentioned ratio of silica gel and fluorescent powder.

[0037] The light-emitting diode composed of the lens of this embodiment is mainly composed of a chip 5, a heat-conducting copper column 1, an electrode line 2, a bracket 3, a gold wire 4, a lens 7, and a silica gel 6. The heat-conducting copper column 1 is embedded in the electrode line 2 In the bracket 3, the chip 5 is fixed on the heat-conducting copper column 1 through silver glue, and the bracket 3 and the chip 5 are connected through the gold wir...

Embodiment 3

[0039] The light-emitting diode white light lens in this embodiment is molded from lens substrate polymethyl methacrylate and phosphor powder with a wavelength of 620 nanometers, and the mass ratio of the lens substrate to phosphor powder is polymethacrylic acid Methyl ester: phosphor = 4:1. The light-emitting diode white light lens of this embodiment is formed by injection molding at a temperature of 150° C. to 200° C. after mixing polycarbonate and phosphor in the above ratio to form a white light lens with a semicircular cross section.

[0040] The structure of the light-emitting diode composed of lenses applied in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com