Light source for optical automatic detector

An optical automatic and detector technology, applied in the direction of light source, point light source, scientific instrument, etc., can solve the problems that it is difficult to distinguish solder joints from the bottom plate, affect the accuracy of image analysis, etc., and achieve solder joint positioning and detection accuracy , easy control, simple light source structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

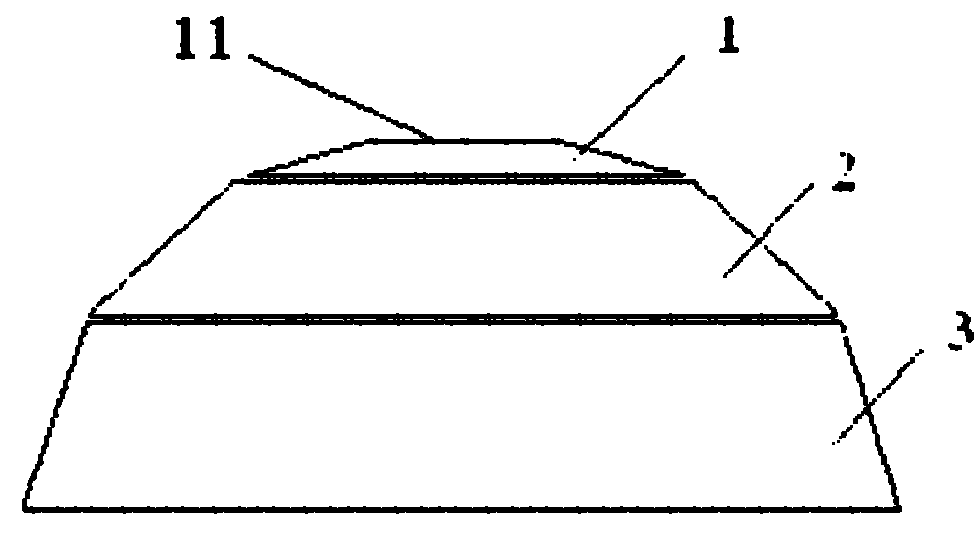

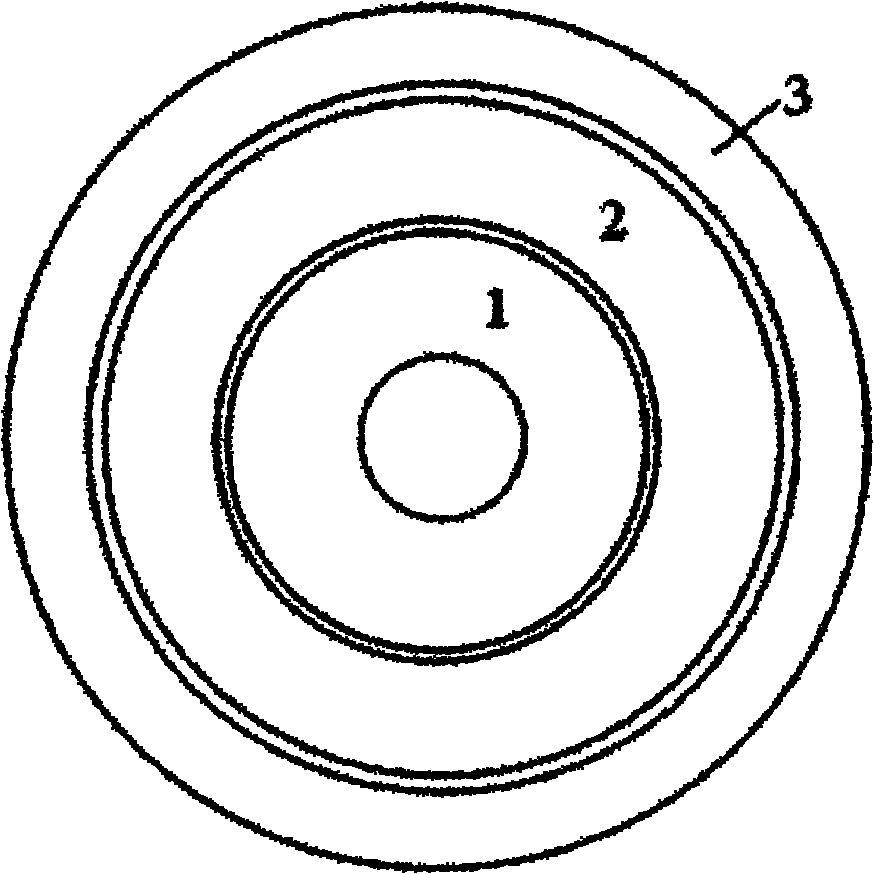

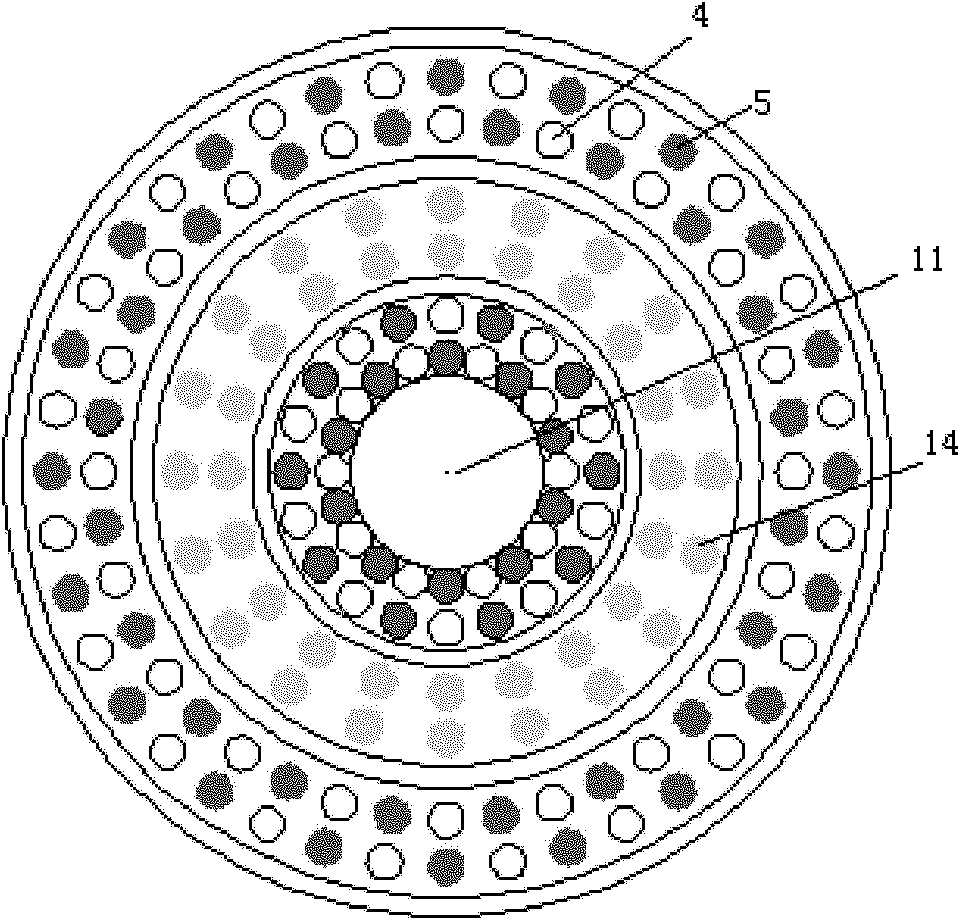

[0019] Such as figure 1 with figure 2 As shown, a light source for an optical automatic detector includes three annular LED arrays stacked coaxially in three layers and a middle through hole 11. The three annular LED arrays are all in the shape of a circular table, and the LED lights are embedded in the The inner side of the circular platform; one of the red and blue two-color circular LED array 1 is located on the top layer, which is used to provide high-angle lighting; one green circular LED array 2 is located on the middle layer, and is used to provide medium-angle lighting; the other red and blue two-color circular LED array 3 is located on the The bottom layer is used to provide low-angle lighting; each red and blue two-color annular LED array is divided into red and blue groups according to the LED color and connected to the external control device respectively, and the green annular LED array 2 is separately connected to the external control device; the external camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com