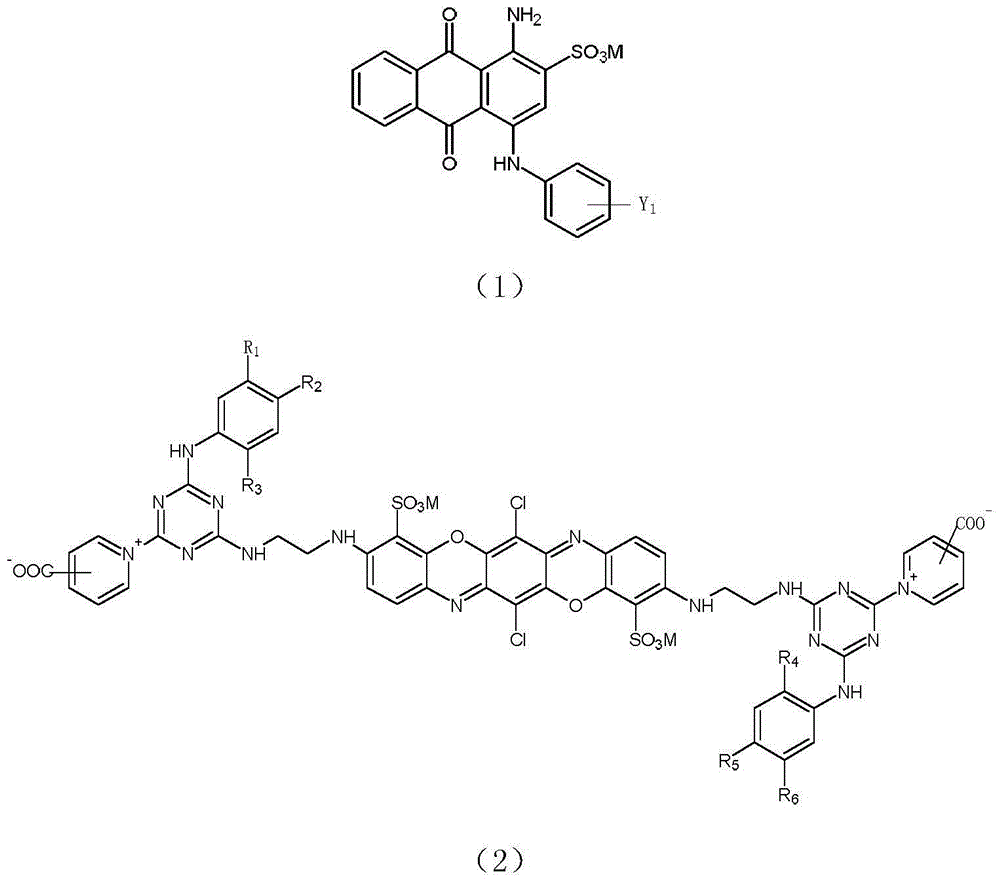

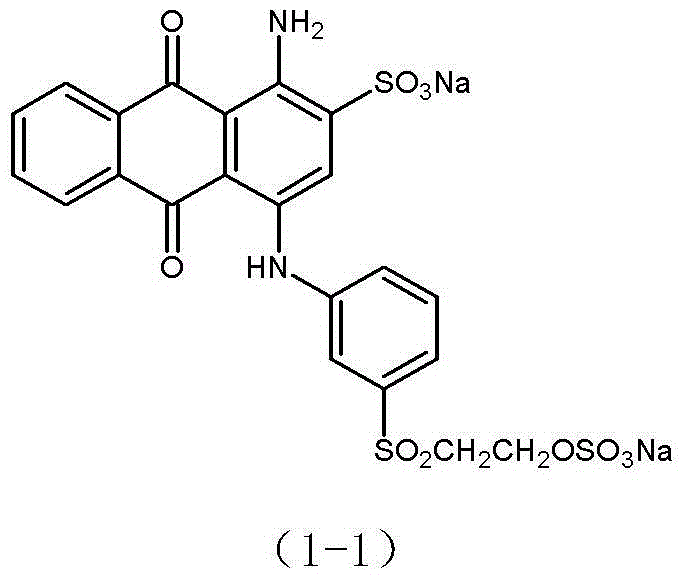

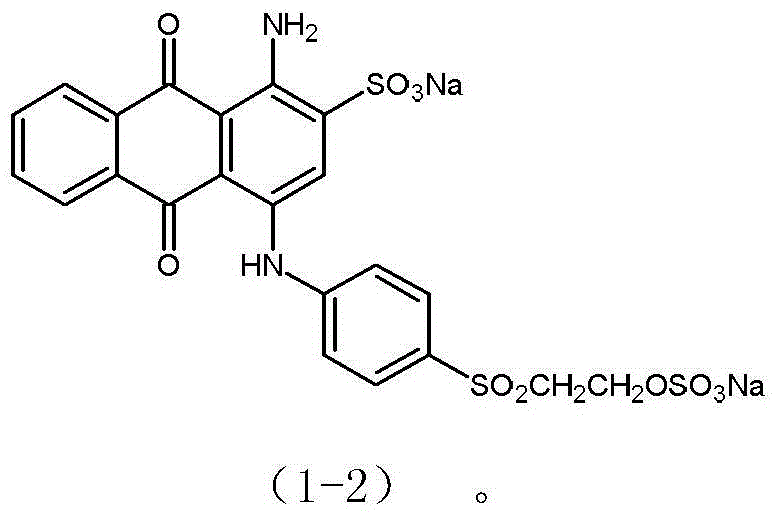

Composite active blue dye

A technology of reactive blue and dyes, applied in the field of dyes, can solve problems such as unsatisfactory results, and achieve good light fastness, good alkali resistance, and good color tone reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Several formulas were screened out based on superior application performance and other characteristics, and the specific ratios are shown in Table 1.

[0028] Table 1

[0029]

[0030]

[0031] Each reactive dye composition in the above-mentioned Table 1 is carried out dry powder mixing in the mixing tank, or spray drying after dissolving together. There are other reactive dye compositions that are not listed one by one, but are included in the present invention.

Embodiment 2

[0032] Embodiment 2: 100g cotton cloth, the composite type reactive blue dye composition that obtains by embodiment 1, by the weight 2% of fabric, in the dyeing bath that contains 60g / l sodium sulfate, bath ratio is 20:1, 60 ℃ Absorb for 30 minutes, add soda ash (amount of 15-20g / l) to fix the color for 45 minutes. The dyed fabric is washed, soaped and dried. The obtained dyed cotton cloth has uniform color and satisfactory light and wet treatment fastness. The specific performance is shown in Table 2.

[0033] Table 2

[0034]

[0035]

[0036] According to a large number of experimental detections, the composite reactive blue dye of the present invention has better application performance than the traditional brilliant blue dye, and the specific comparative data are shown in Table 3.

[0037] table 3

[0038]

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com