Reactive printing dye and application of liquid composition thereof

A reactive dye and reactive technology, applied in the field of liquid reactive printing dye composition, cellulose fiber printing and dyeing, and reactive printing dye composition, can solve the problem of chlorine bleaching fastness, dye solubility and storage stability. Good light fastness, good wet fastness, clear outline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

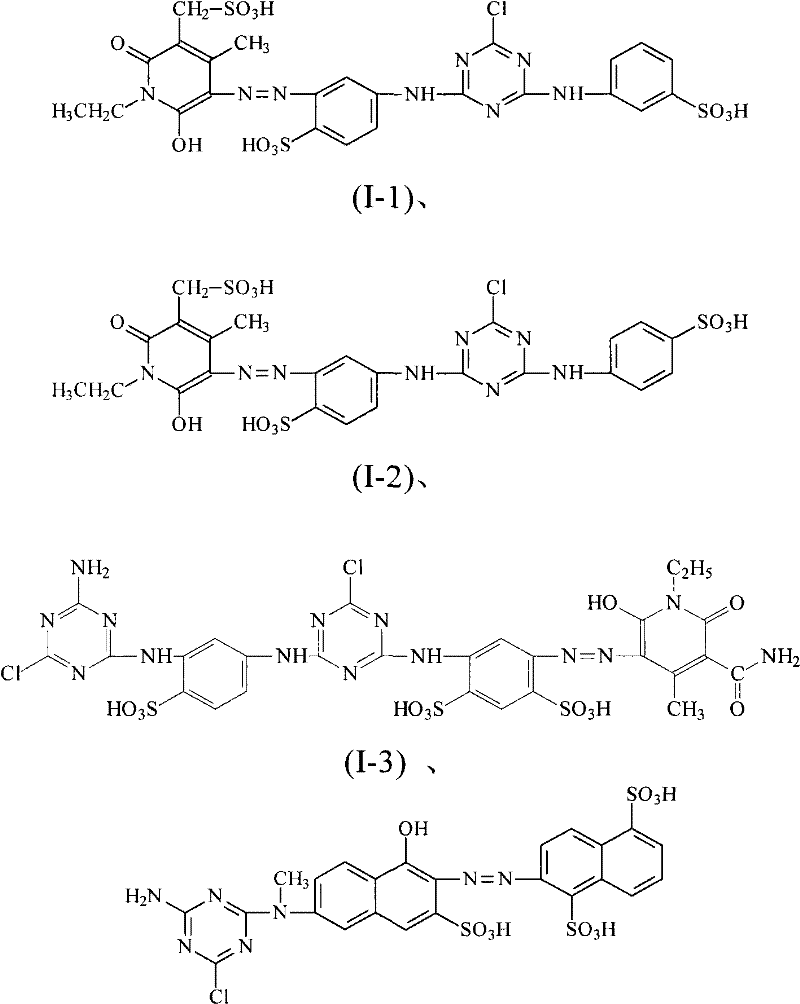

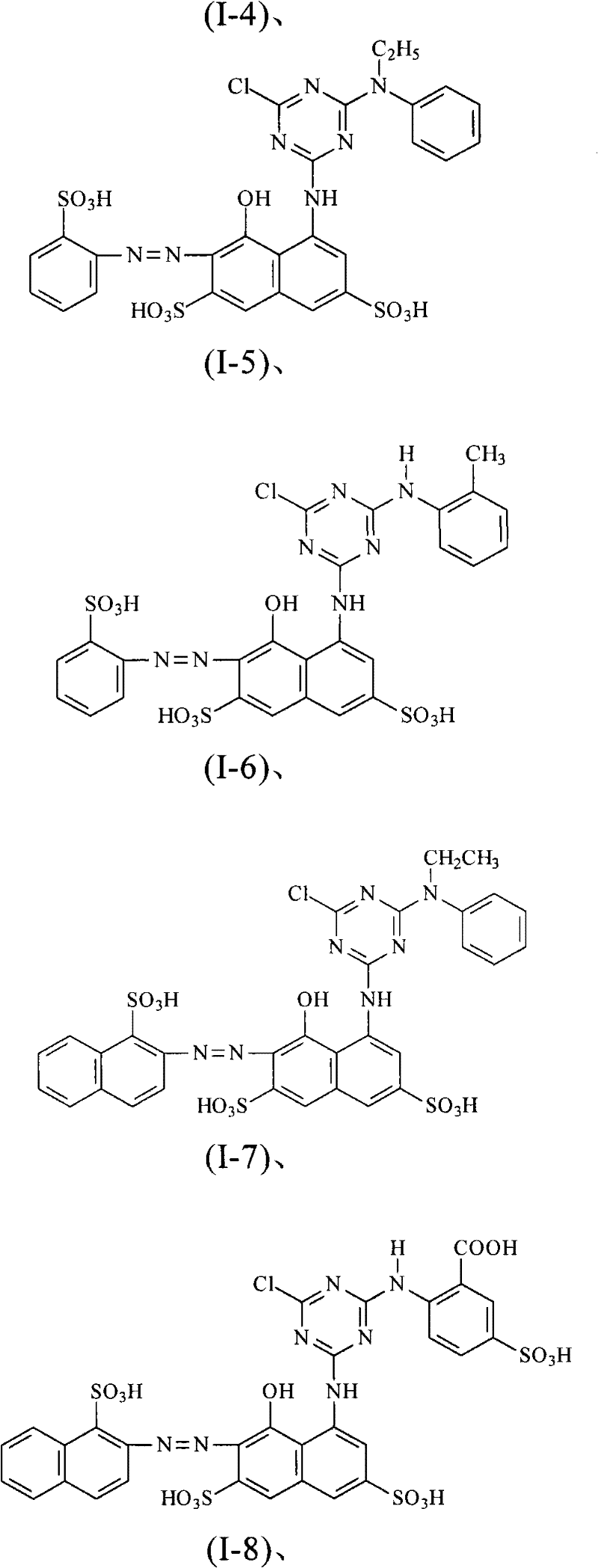

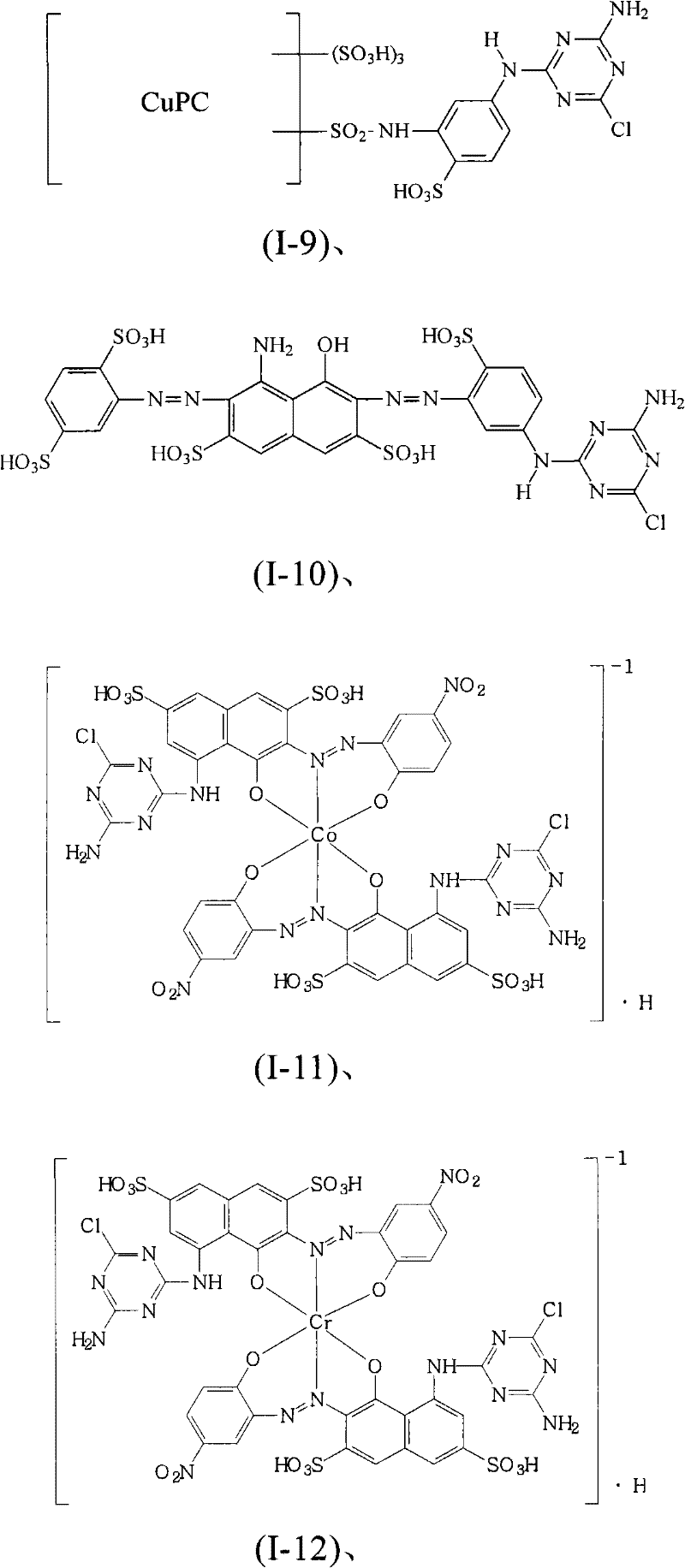

Embodiment 1

[0064] Take 50 parts of the compound of formula (I-1) and 50 parts of the compound of formula (I-2), add 300 parts of water and mix well, then adjust the pH value to 5.5-8.5. After desalination by reverse osmosis to make the salt content less than 0.5% by weight, add 2 parts of the compound of formula (II-1) and stir evenly and adjust the pH value to 6.0-8.5. Finally, spray the solution to dry to obtain the reactive printing dye composition of this embodiment.

Embodiment 2

[0066] Take 100 parts of the compound of formula (I-3), add 300 parts of water and mix well, then adjust the pH value to 5.5-8.5. After purification, 5 parts of the compound of formula (II-1) and 30 parts of mangolin were added and stirred evenly, and the pH value was adjusted to 6.0-8.5. Finally, spray the solution to dry to obtain the reactive printing dye composition of this embodiment.

Embodiment 3

[0068] Take 100 parts of the compound of formula (I-4), add 300 parts of water and mix well, then adjust the pH value to 5.5-8.5. After desalting by reverse osmosis to make the salt content less than 0.5% by weight, add 2 parts of the compound of formula (II-1) and 20 parts of Demol RN, stir evenly and adjust the pH value to 6.0-8.5. Finally, spray the solution to dry to obtain the reactive printing dye composition of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com