Environment-friendly emulsion modified acrylate pigment dyeing adhesive and manufacturing method thereof

An acrylic and paint dyeing technology, applied in the direction of dyeing method, adhesive type, graft polymer adhesive, etc., can solve problems such as poor rubbing fastness, high fabric hardness, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

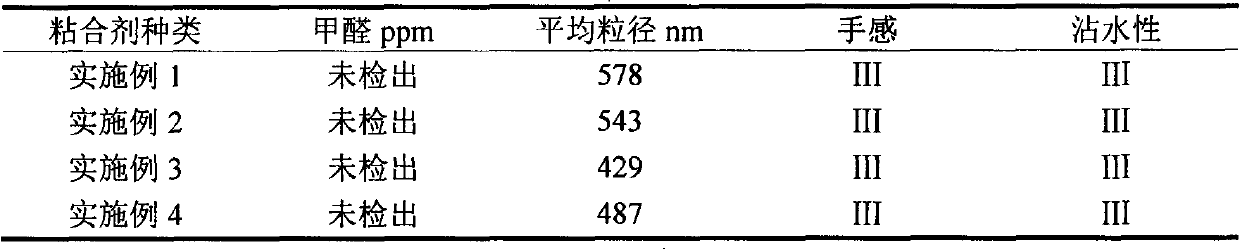

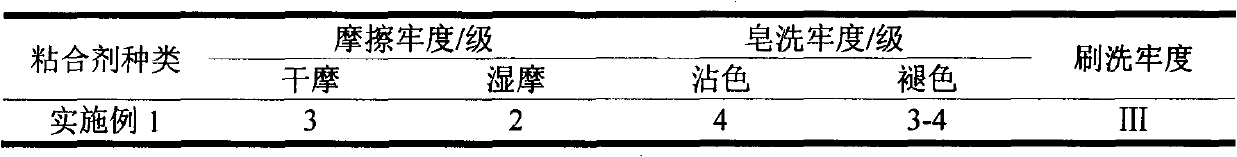

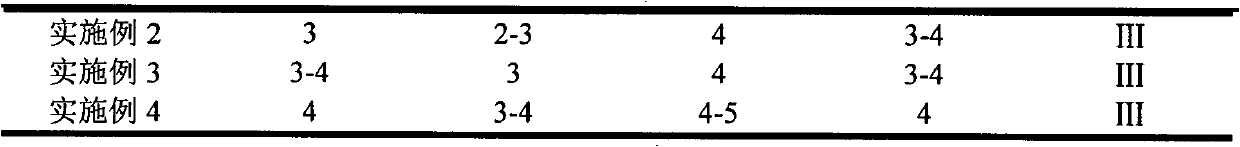

Examples

Embodiment 1

[0025]A kind of preparation method of environment-friendly emulsion modified acrylate paint dyeing adhesive of the present invention is characterized in that the preparation method comprises the following steps:

[0026] (1) select the composition of methyl methacrylate, methyl acrylate, ethyl acrylate, glycidyl acrylate and acrylic acid for use, described methyl methacrylate, methyl acrylate, ethyl acrylate, glycidyl acrylate The amount ratio with acrylic acid is 1.3: 2.4: 3.1: 1.4: 2.6 in molar ratio;

[0027] (2) A mixture of octamethylcyclotetrasiloxane and low-viscosity hydroxy silicone oil is used as a raw material A, and 1,1,3,3-tetramethyldisiloxane is put in at a weight ratio of 4:20 In a high-speed rotary stirred tank with a rotation speed of 785 rpm, 35% of the weight of the raw material A was added as an initiator ceric ammonium nitrate at the same time, and the reaction was stirred for 15 minutes at a temperature of 95°C, and 5% of the weight of the raw material A...

Embodiment 2

[0033] A kind of preparation method of environment-friendly emulsion modified acrylate paint dyeing adhesive of the present invention is characterized in that the preparation method comprises the following steps:

[0034] (1) select the composition of methyl methacrylate, methyl acrylate, ethyl acrylate, glycidyl acrylate and acrylic acid for use, described methyl methacrylate, methyl acrylate, ethyl acrylate, glycidyl acrylate The amount ratio with acrylic acid is 1.3: 2.4: 3.1: 1.4: 2.6 in molar ratio;

[0035] (2) A mixture of octamethylcyclotetrasiloxane and low-viscosity hydroxy silicone oil is used as a raw material A, and 1,1,3,3-tetramethyldisiloxane is put in at a weight ratio of 4:20 In a high-speed rotary stirred tank with a rotation speed of 785 rpm, 35% of the weight of the raw material A was added as an initiator ceric ammonium nitrate at the same time, and the reaction was stirred for 15 minutes at a temperature of 95°C, and 5% of the weight of the raw material ...

Embodiment 3

[0041] A kind of preparation method of environment-friendly emulsion modified acrylate paint dyeing adhesive of the present invention is characterized in that the preparation method comprises the following steps:

[0042] (1) select the composition of methyl methacrylate, methyl acrylate, ethyl acrylate, glycidyl acrylate and acrylic acid for use, described methyl methacrylate, methyl acrylate, ethyl acrylate, glycidyl acrylate The amount ratio with acrylic acid is 1.3: 2.4: 3.1: 1.4: 2.6 in molar ratio;

[0043] (2) A mixture of octamethylcyclotetrasiloxane and low-viscosity hydroxy silicone oil is used as a raw material A, and 1,1,3,3-tetramethyldisiloxane is put in at a weight ratio of 4:20 In a high-speed rotary stirred tank with a rotation speed of 785 rpm, 35% of the weight of the raw material A was added as an initiator ceric ammonium nitrate at the same time, and the reaction was stirred for 15 minutes at a temperature of 95°C, and 5% of the weight of the raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com