Device for measuring three-dimensional ground stress of deep rock

A technology of in-situ stress and rock mass, applied in measurement, wellbore/well components, earthwork drilling and production, etc., can solve problems such as limited drainage capacity in holes, unsatisfactory arrangement forms, and abnormal operation of instruments, etc., to achieve Reduce the risk of hole wall instability, reduce human intervention, and have a good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

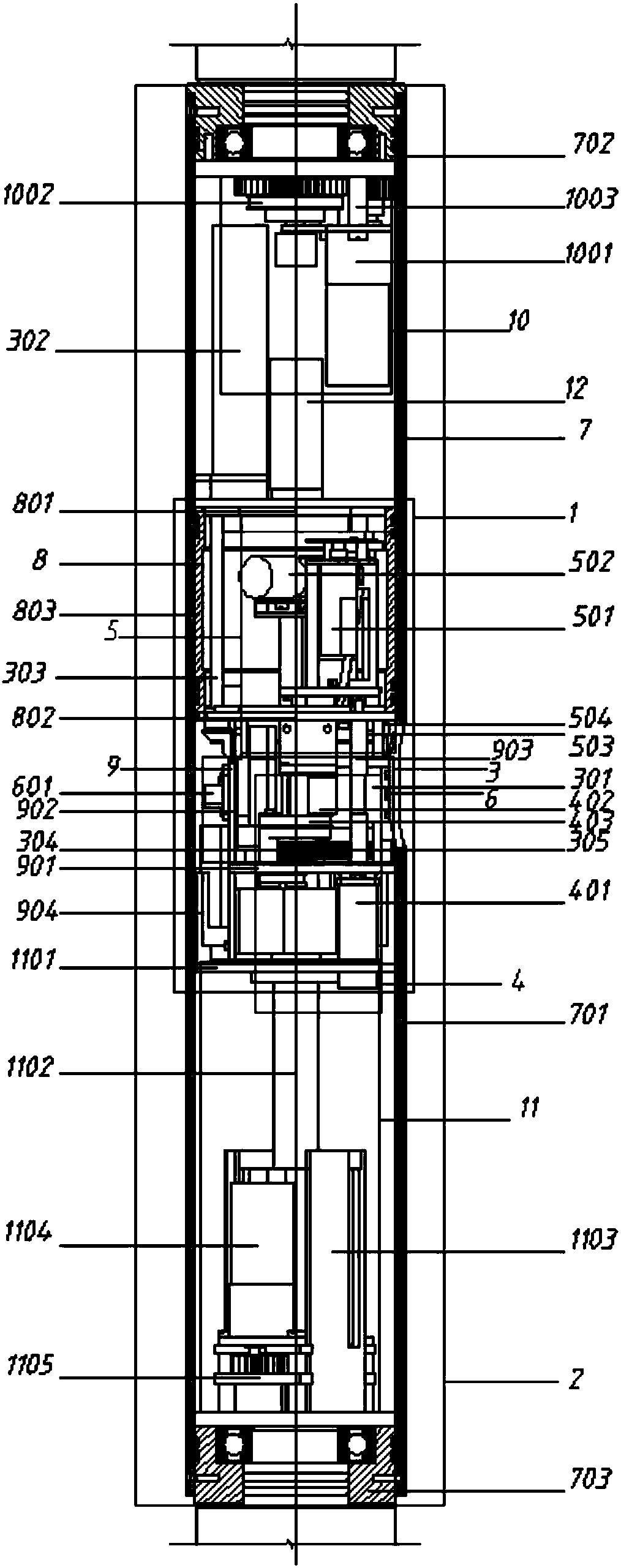

[0032] like figure 1 As shown, a device for measuring the three-dimensional geostress of deep rock mass consists of a main detection part 1, a mobile frame and a sealing assembly 2, an annular groove cutting device 3, a rock surface grinding device 4, glue coating and strain gauge stripping Device 5, strain gauge patch device 6, outer sealing sleeve 7, inner sealing sleeve 8, mobile frame 9, slewing device 10, longitudinal moving device 11, hot air blower 12, thin-walled coring drill bit 301, main power motor 302, Main power transmission shaft 303, ring cutting feed motor 304, feed mechanism support 305, feed push screw rod 306, grinding drive motor 401, rotating grinding head 402, grinding mechanical arm 403, glue coating and stripping mechanism 501, glue bottle 502, spraying mechanical arm 503, peeling mechanical arm 504, strain gauge patching mechanism 601, hollow cylinder 701, upper end cover 702, lower end cover 703, upper machine base plate 801, middle machine base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com