Plugging agent with high bearing strength for deep drilling and preparation method thereof

A technology of high pressure-bearing and loss-stopping agent, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems of fragile strata and difficulty of sealing with loss-stopping agent, etc., so as to improve the cementing performance and improve the pressure-bearing capacity. ability, the effect of saving drilling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

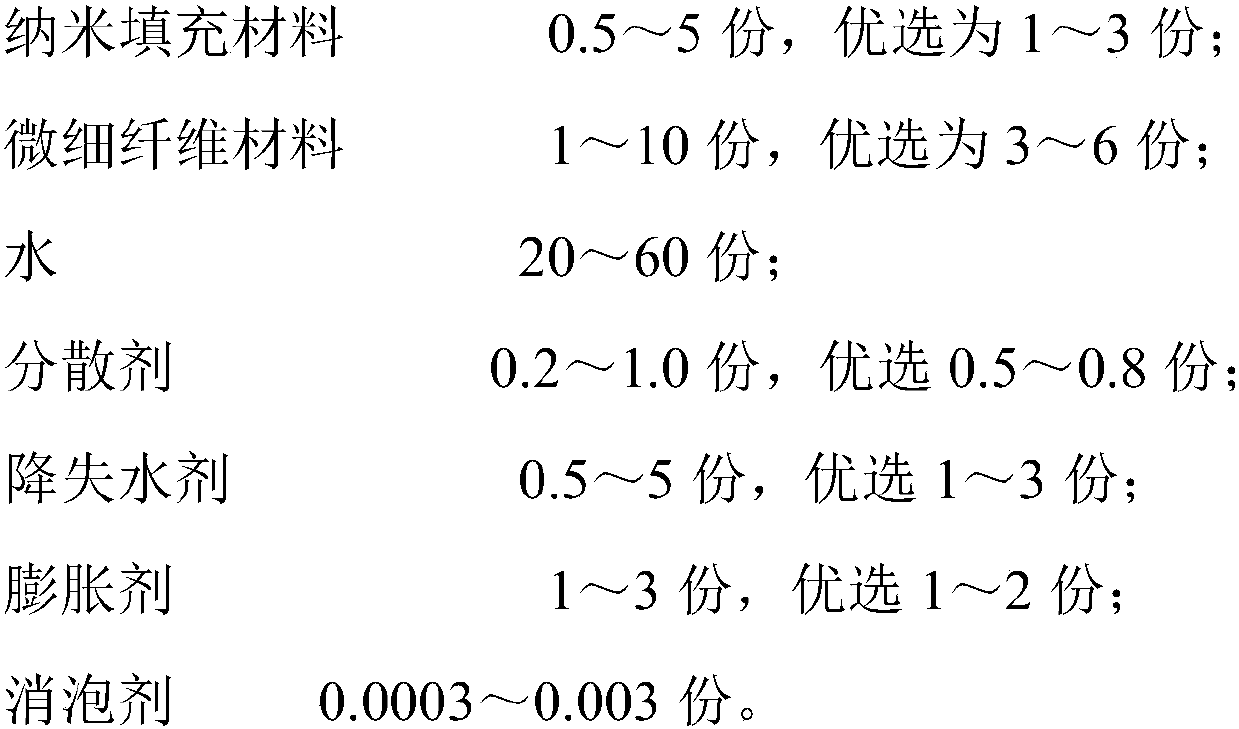

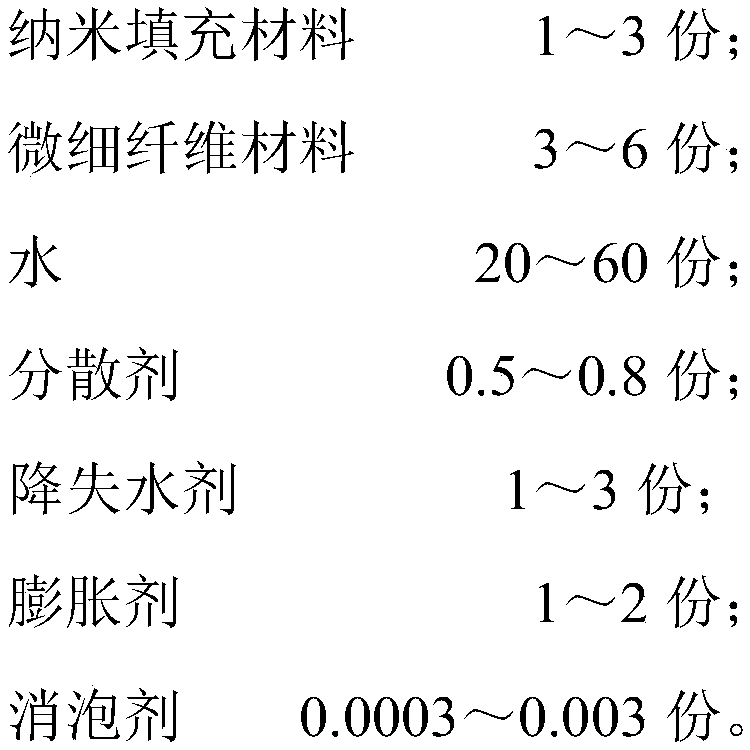

Method used

Image

Examples

Embodiment 1

[0041] Take 100 parts of Jiahua G grade oil well cement, 0.5 parts of lignosulfonate dispersant (GMP-3 chrome-free thinner), 1.2 parts of polyvinyl alcohol fluid loss reducer (FSAM non-permeable fluid loss reducer), sulfur Calcium aluminate cement expansion agent 1 part (DZP lattice expansion agent), mix well (dry mixing).

[0042] Add 44 parts of water to the slurry cup of the M3080 constant speed stirrer, and add 2 parts of silicon dioxide with a particle size between 30 and 60 nm and 0.001 part of silicone defoamer silicone oil under stirring at 2000 rpm.

[0043] Quickly add the dry mixture into the slurry cup of the constant speed stirrer, and stir at high speed (12000 rpm) for 50 seconds. Add 3 parts of steel wires with a diameter ranging from 0.1 to 1 mm and a length ranging from 5 to 30 mm into the prepared cement slurry, and stir at a low speed for 20 seconds to prepare the high compressive strength plugging agent of the present invention.

[0044] Pour the plugging ...

Embodiment 2

[0046] Take 100 parts of Jiahua G grade oil well cement, 0.5 parts of lignosulfonate dispersant (FCLS), 1.2 parts of polyvinyl alcohol (RC800) fluid loss reducer, calcium sulfoaluminate cement expansion agent (DZP lattice expansion agent) 1 part, mix well (dry blend).

[0047] Add 44 parts of water to the slurry cup of the M3080 constant speed stirrer, and add 1 part of silicon dioxide with a particle size range of 30-60 nm and 0.001 part of silicone defoamer methyl silicone oil under stirring at 2000 rpm. Quickly add the dry mixture into the slurry cup of the constant speed stirrer, and stir at high speed (12000 rpm) for 50 seconds. Add 5 parts of steel wires with a diameter ranging from 0.1 to 1 mm and a length ranging from 5 to 30 mm into the prepared cement slurry, and stir at a low speed for 20 seconds to prepare the high bearing strength plugging agent of the present invention.

[0048] Squeeze this lost circulation agent into the cracks of the core block, and cure it i...

Embodiment 3

[0050] Take 100 parts of Jiahua G grade oil well cement, 1 part of lignosulfonate dispersant (FCLS), 2 parts of polyvinyl alcohol fluid loss reducer polyvinyl alcohol (RC800) fluid loss reducer, calcium sulfoaluminate type Cement expansion agent (DZP lattice expansion agent) 1.5 parts, mix well (dry mixing).

[0051] Add 44 parts of water to the slurry cup of the M3080 constant speed stirrer, and add 2 parts of nano-silica with a particle size between 30 and 60 nm and 0.002 parts of silicone defoamer methyl silicone oil under stirring at 2000 rpm. Quickly add the dry mixture into the slurry cup of the constant speed stirrer, and stir at a high speed of 12000 rpm for 50 seconds. Add 3 parts of fine steel wires with a diameter of 0.1 to 1mm and a length of 5 to 30mm into the cement slurry prepared above, and stir at a low speed for 20 seconds to obtain the high pressure strength plugging agent No. 2 of the present invention .

[0052] Pour the plugging agent into the curing ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com