Integrally-weighted drilling rod and production and processing method thereof

A drill pipe and integral technology, which is applied in the direction of drill pipe, metal processing equipment, drill pipe, etc., can solve the problems of limited promotion, low strength of drill pipe body, high processing cost, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

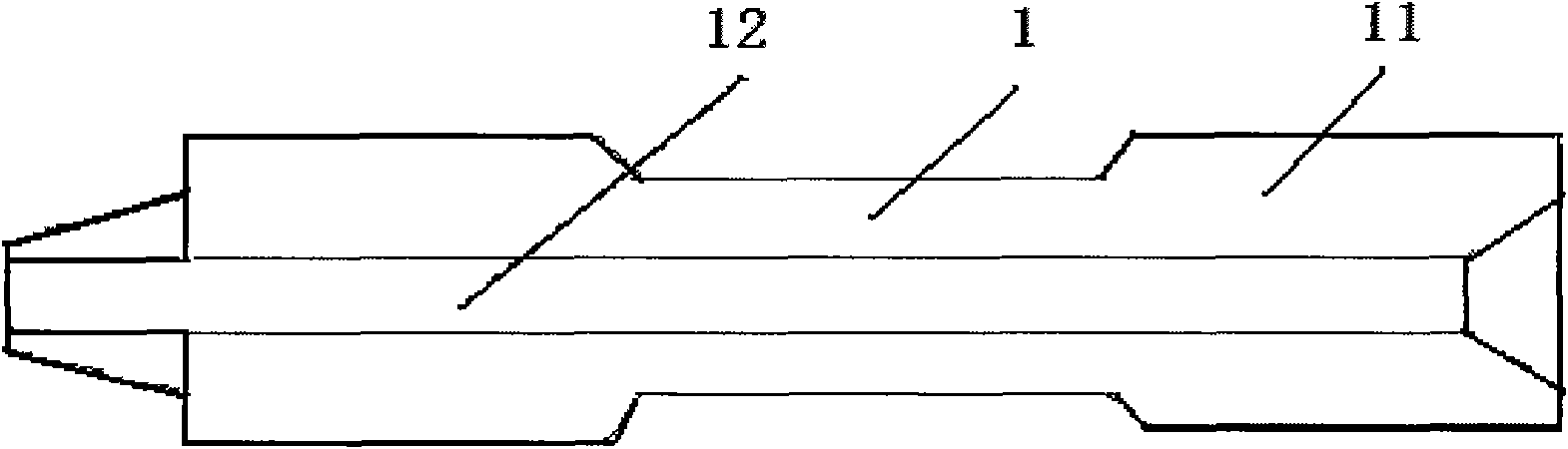

[0018] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the heavy drill rod of the present invention. The invention relates to an overall weighted drill pipe, which is integrally processed from a chrome-molybdenum alloy steel seamless steel pipe. It includes a pipe body 1, a female end 11 arranged at one end of the pipe body, and a male end 12 arranged at the other end of the pipe body; the pipe body, the female end and the male end are all made of chrome-molybdenum alloy steel seamless steel pipe constituted and integrally formed.

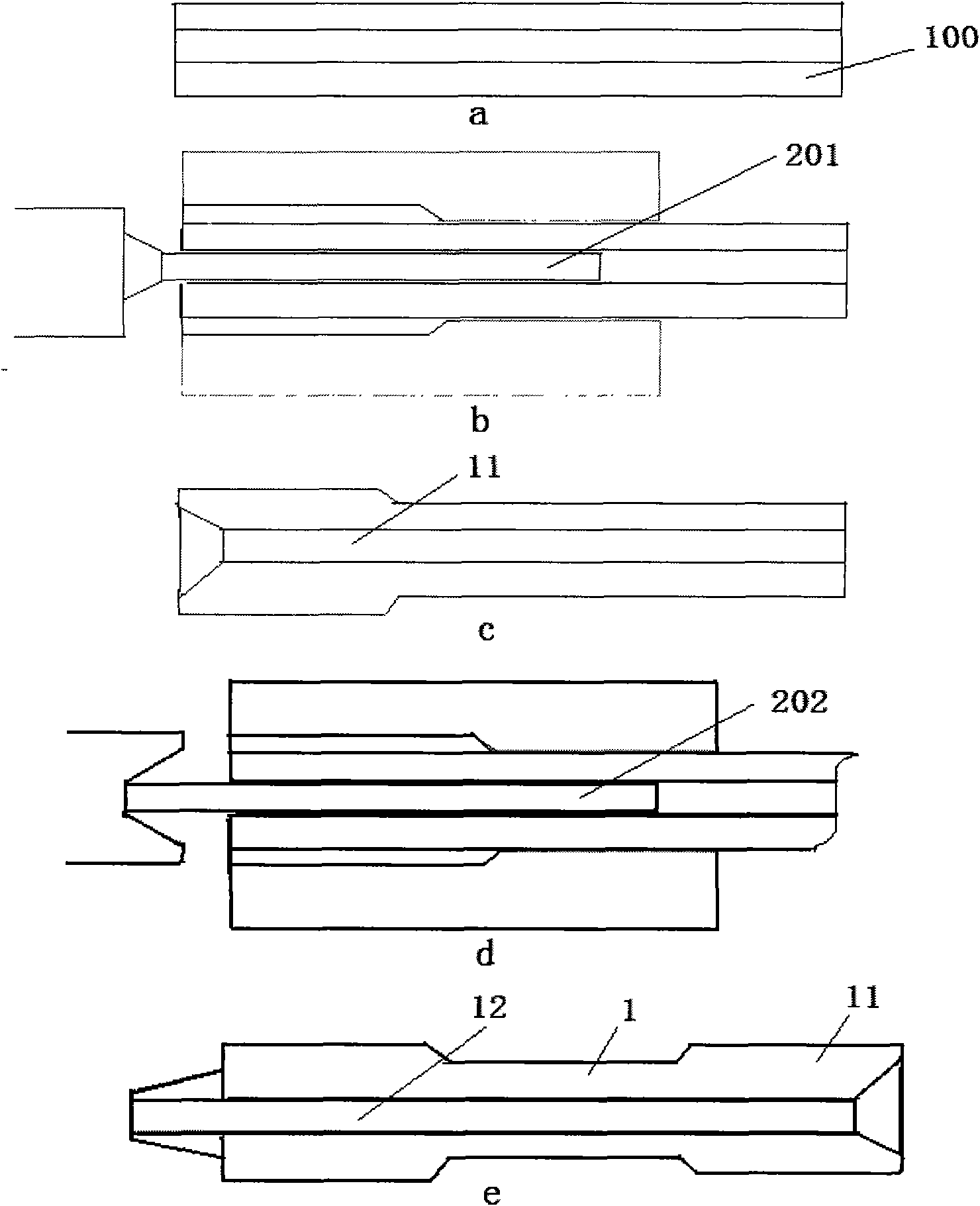

[0019] The method for producing and processing the integrally weighted drill pipe includes a raw material inspection step (1), a processing and forming step (2), and a subsequent processing and finishing step (3); the processing and forming step adopts a pipe end upsetting process.

[0020] The method of the present invention will be described in detail below by taking the production and processing of 31 / 2"~51 / 2"...

PUM

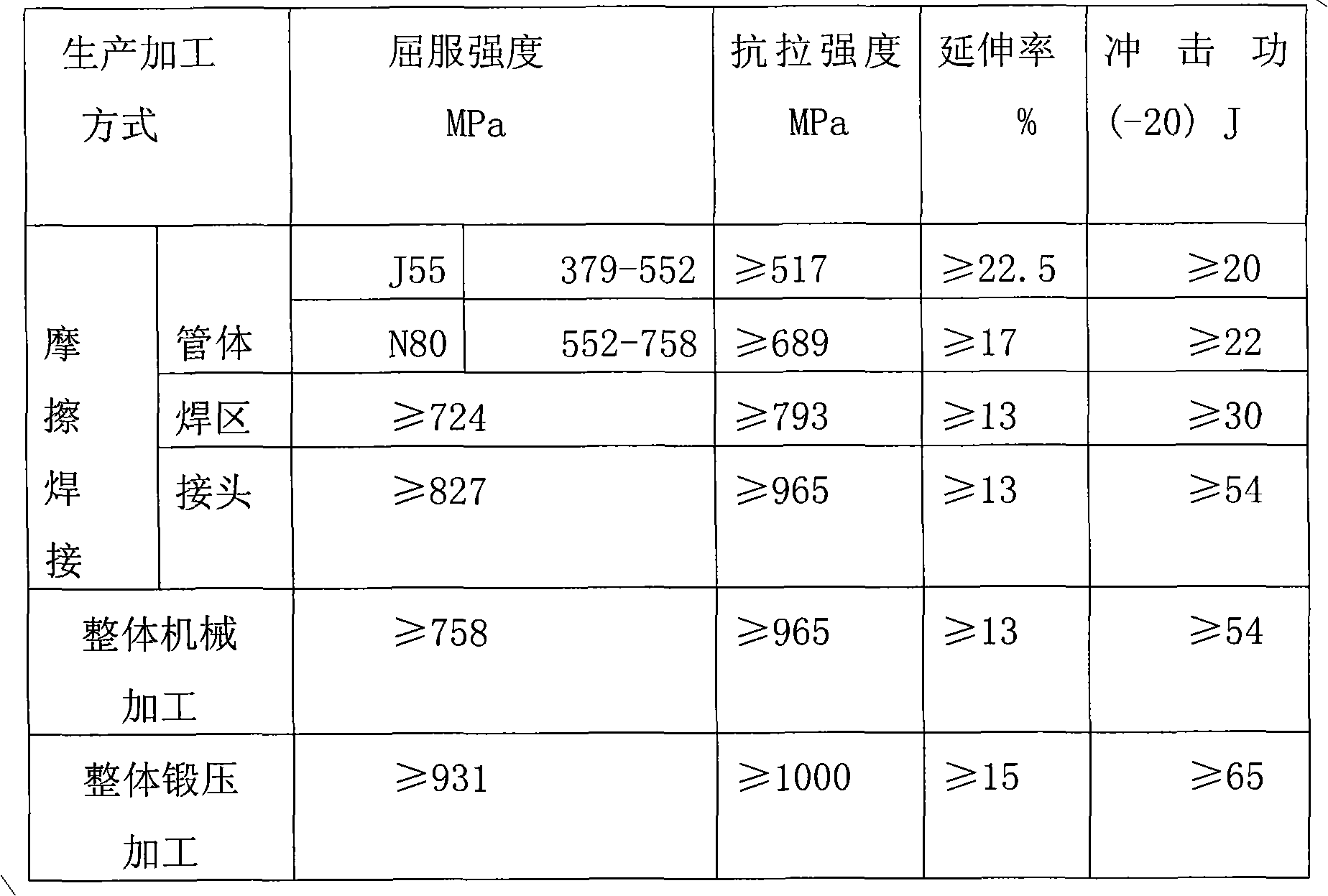

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com