Electronic product clamp

A technology for electronic products and clips, applied in the direction of friction clamping detachable fasteners, connecting components, mechanical equipment, etc., can solve the problems of high manufacturing cost, easy shrinkage, inconvenient to carry, etc. The effect of increasing the service life and meeting the requirements of portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

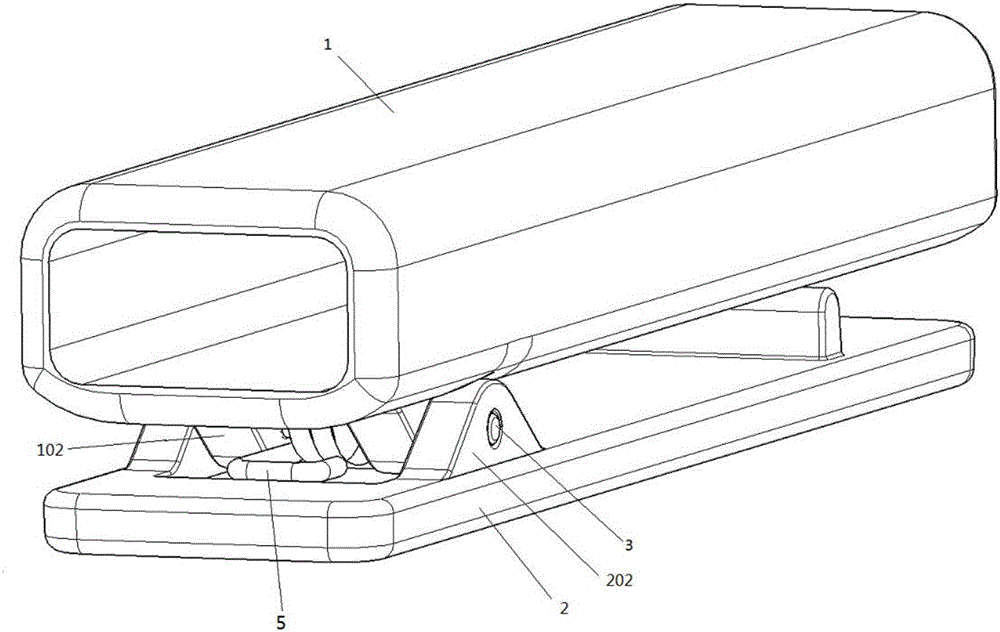

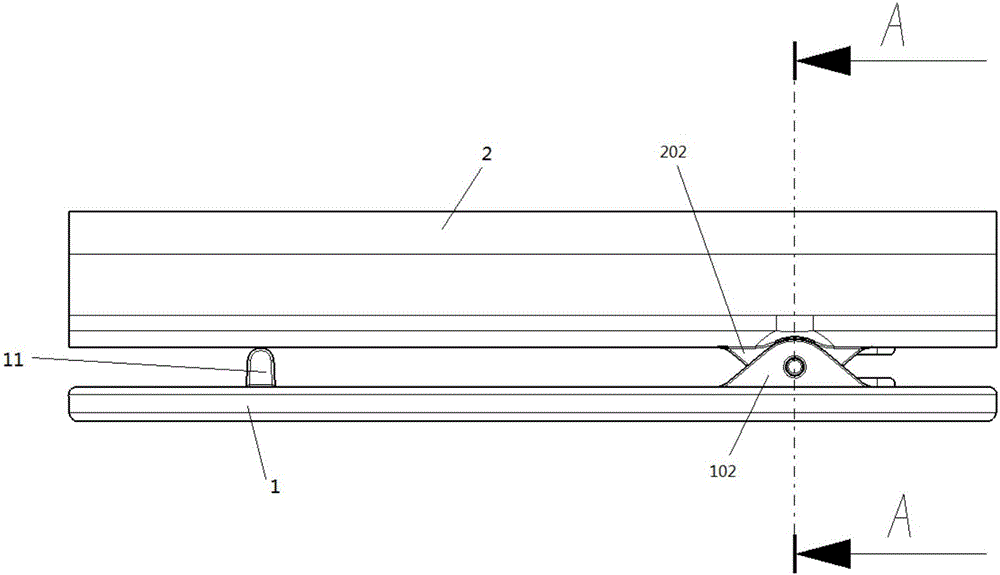

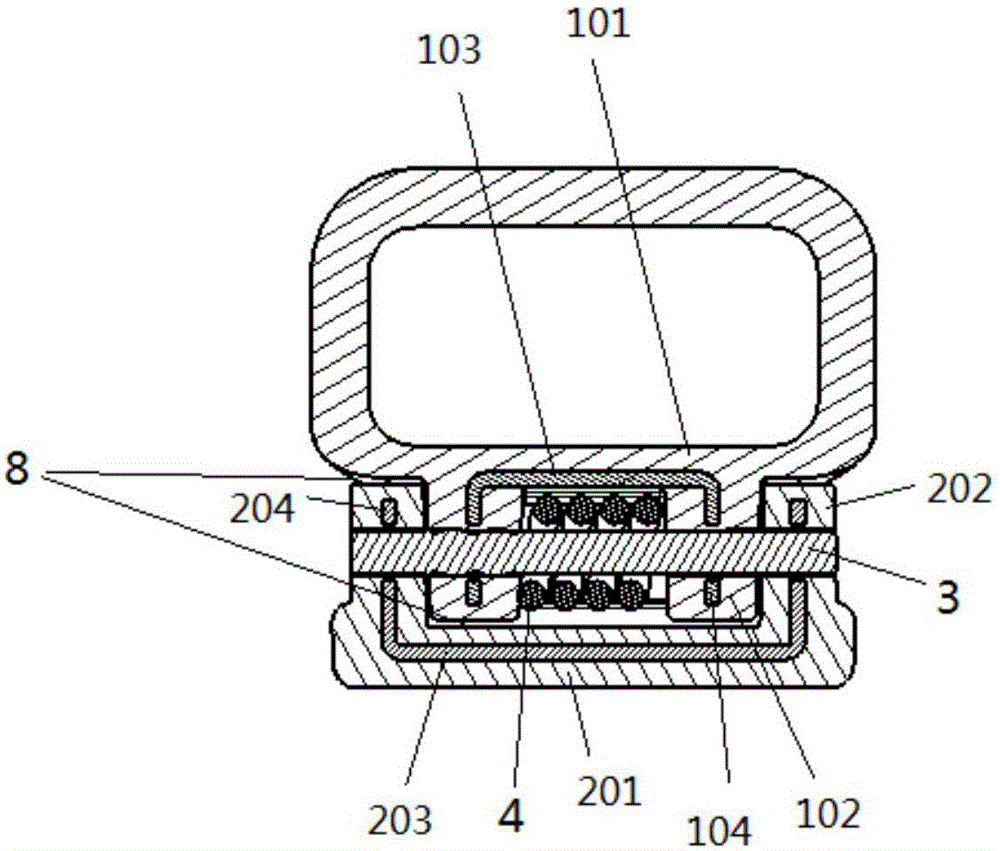

[0032] see Figure 1 to Figure 12 , the electronic product clip includes a first part 1 and a second part 2, the first part 1 includes a first splint 101, the second part 2 includes a second splint 201; both sides of the first splint 101 are provided with shaft holes The shaft hole seat 102 of the first part, and the shaft hole seat 202 of the second part with a shaft hole are arranged on both sides of the second splint 201; the shaft hole seat 202 of the second part is arranged outside the shaft hole seat 102 of the first part;

[0033] The inside of the first part 1 is covered with a first insert, and the inside of the second part 2 is covered with a second insert;

[0034] The first insert comprises a first panel 103 and the second insert comprises a second panel 203;

[0035] Both sides of the first panel 103 are provided with a first insert shaft hole seat 104 with a shaft hole, and both sides of the second panel 203 are provided with a second insert shaft hole seat 204 ...

Embodiment 2

[0042] In this embodiment, the description is focused on the materials and structures of the first insert and the second insert of the electronic product clip. For other contents, refer to other embodiments of the present invention.

[0043] In the electronic product clip of this embodiment, both the first insert and the second insert are made of metal.

[0044] It should be noted that the electronic product clip of the present invention can effectively reduce the influence of metal on the radio frequency performance of electronic products by embedding a metal insert in the shaft hole seat of the plastic material clip, and at the same time make the electronic product The product clip not only has the high strength performance of metal clips, but also has the good appearance performance of plastic clips.

[0045] Preferably, the lengths of the first panel 103 and the second panel 203 account for 20%-30% of the lengths of the first splint 101 and the second splint 201 respective...

Embodiment 3

[0050] This embodiment focuses on the description of a specific realization of the structure required by the manufacturing process of the clip for electronic products. For other content, refer to other embodiments of the present invention.

[0051] see Figure 6 , Figure 7 , Figure 10 and Figure 11 , In the electronic product clip of this embodiment, the first insert and the second insert are respectively provided with a space-avoiding through hole 6 and a space-avoiding groove 7 .

[0052] It should be noted that, in the electronic product clip of the present invention, the first part 1 and the second part 2 made of plastic are respectively coated on the outside of the first insert and the second insert made of metal, and the first part 1 made of plastic 1. The second part 2 can be made by injection molding process respectively, and its air-avoiding through hole 6 can be set as a circular hole or a rectangular hole according to needs and actual conditions, and its numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com