Method for deep drilling print circuit board

A technology of printed circuit boards and drilling methods, which is applied in the direction of removing conductive materials by mechanical means, can solve problems affecting drilling accuracy, etc., and achieve the effect of improving control accuracy and controlling influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

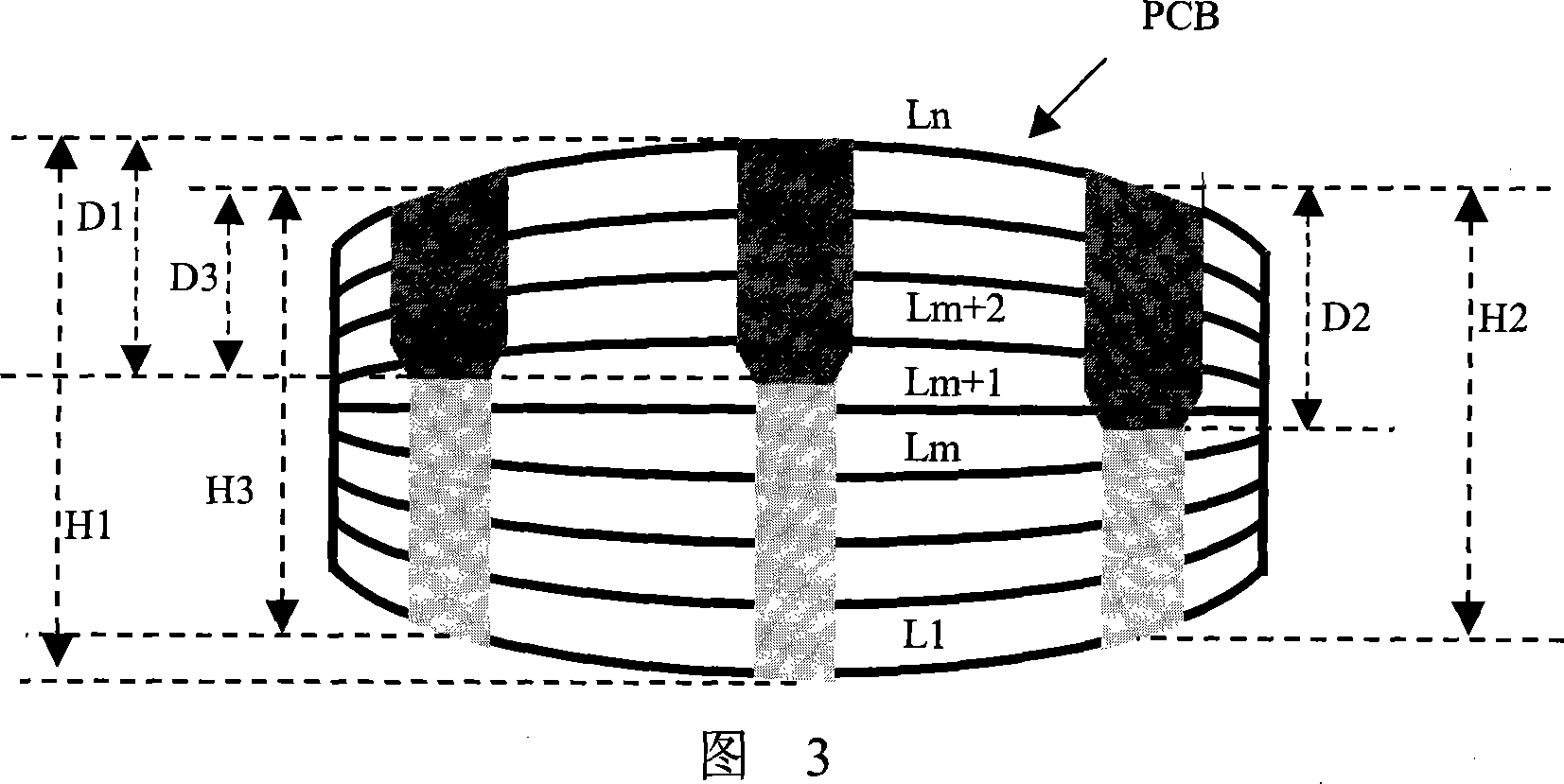

[0023] Example: As shown in Figure 3, the thickness of the laminated printed circuit board is uneven, but it has certain rules. Generally, the thickness of the board will be thick in the middle and thin on both sides, and the change is relatively uniform .

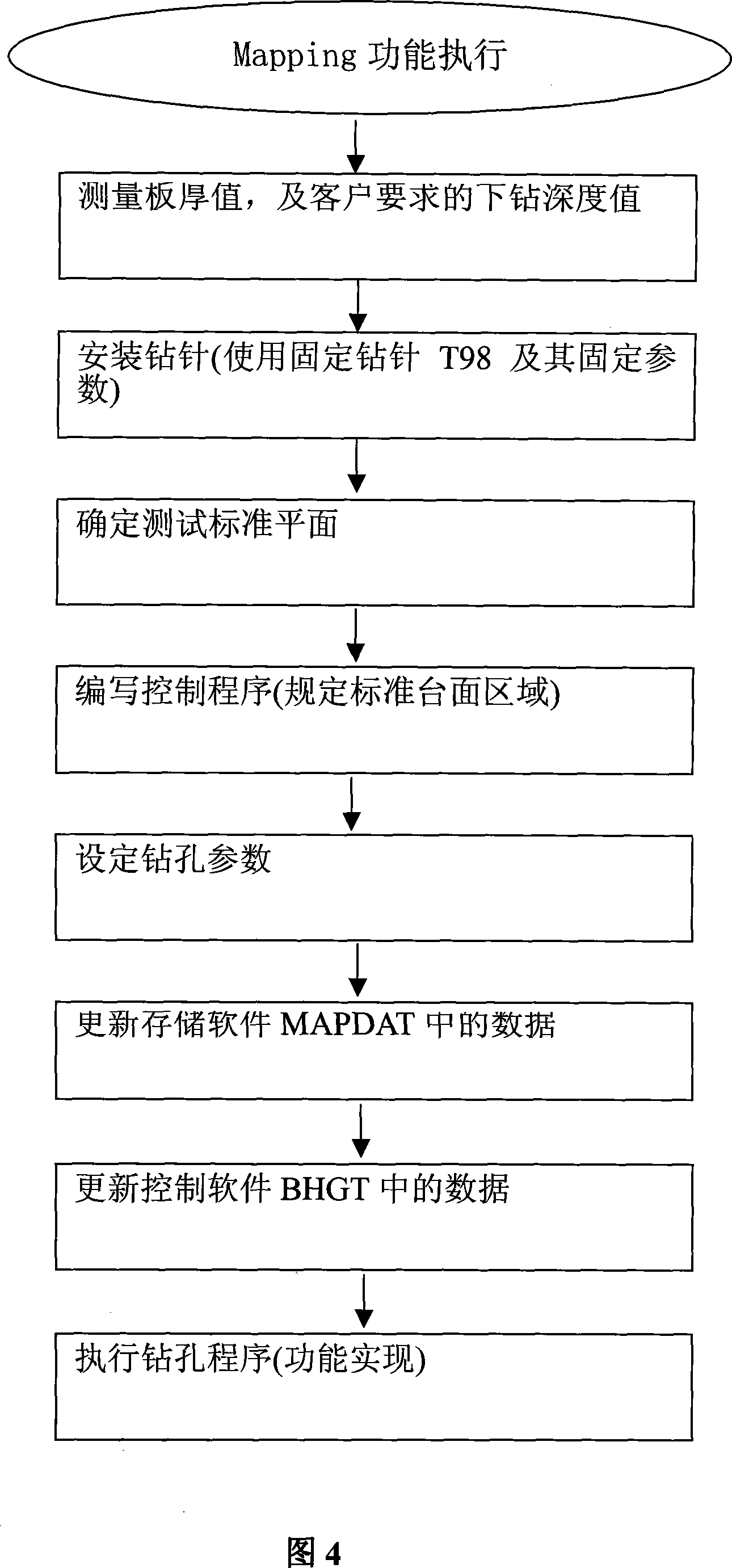

[0024] Suppose the customer asks us to control the depth between Lm+1 and Lm+2 layers, then we name Lm+1 layer as the target layer, Lm+2 layer as the layer above the target layer, and Lm layer as the layer below the target layer. As shown in Figure 3, if the thickness uniformity of the produced printed circuit board is poor and we still use the old method when drilling deep, even if drilling at the same depth, it is easy to drill the target layer and cause scrapping, or use The length of residual hole copper calculated from layer Lm+1 to layer Ln is different. Therefore, it is necessary to let the machine automatically detect the surface of the board, calculate the height of the board at this time, and automatically set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com