Pipe-following drilling reaming device for gas extraction holes in soft broken coal bed

A technology for coal seam gas and pipe-following drilling, which is applied to drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of difficulty in deep hole drilling and poor hole-forming effect in gas drainage holes, and achieve high gas drainage efficiency. , easy to operate, the effect of improving the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

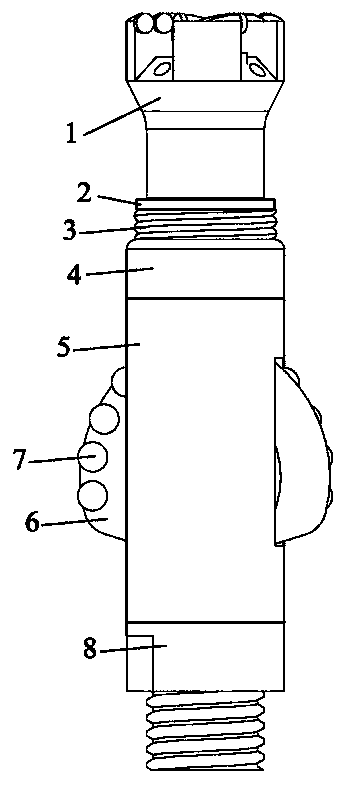

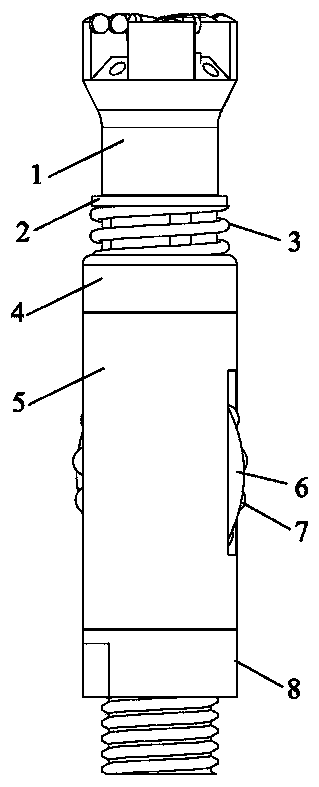

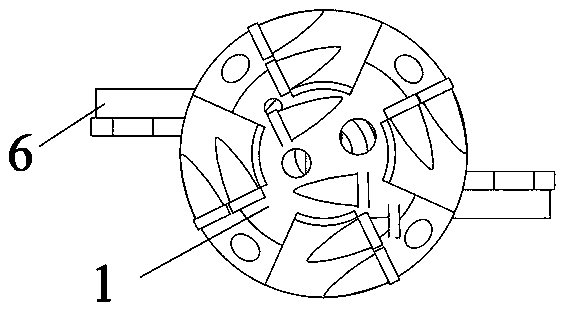

[0021] Depend on Figure 1-14 Provided, the present invention includes a drill bit, a drill bit connector, a reaming tool opening and closing member, a casing and a drill pipe connector, the drill bit 1 is connected with the drill bit connector 9, and the drill bit connector 9 is placed in the casing 5, and the sleeve There is a top cap 4 on the upper end of the pipe 5, and a spring 3 is set on the drill connector 9. The upper and lower ends of the spring 3 are respectively fixed by the washer 2 and the top cap 4. Under the action of the spring 3, the drill connector 9 slides up and down, and the reaming tool The opening and closing member is placed in the casing 5 and consists of a pair of scrapers 6, a mandrel 10 and a cutter tube 11. The scraper 6 is installed in the scraper groove 16 in the casing 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com