Lunar soil deep drilling sample recycling mechanism

A recovery mechanism and deep drilling technology, which is applied in the direction of earth drilling, rotary drilling rigs, drill pipes, etc., can solve the problems of inability to sample drill pipes, and achieve the effect of flexible sampling, large sampling volume and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

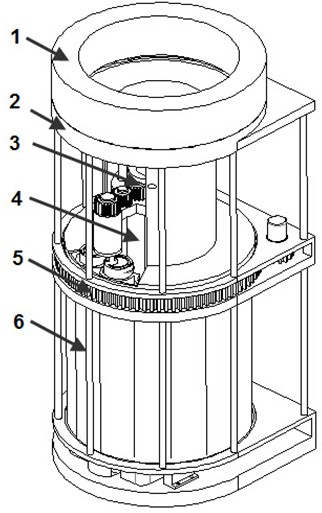

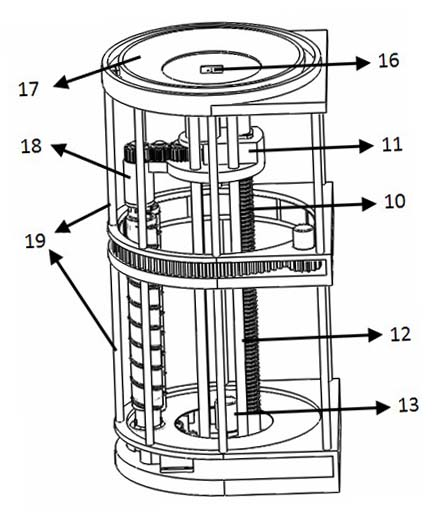

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a drill joint 1, a frame part, a drilling part and a rod changing part.

[0023] During the work of the present invention, at first the drilling machine frame 2 is clamped by the drilling machine joint 1 fixed on the mechanical arm, and the drilling machine is moved to the designated sampling site; then the drilling pipe is moved under the action of the drilling pipe carousel box mechanism 15 and the deep drilling motor 3, Connection, sampling and recovery; after sampling is completed, the drill joint clamps the drill pipe part for sample recovery.

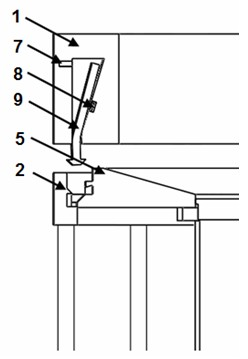

[0024] The drill joint 1 is a cylindrical ring, which is divided into three wedge-shaped spaces in the circumferential direction, and a buckle rocker 9 is installed in each wedge-shaped space. One side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com