Floating type automatic descending sampling device for water body detection

A technology for automatic detection and sampling equipment, applied in the direction of sampling devices, etc., can solve the problems of personal safety, difficult to control sampling depth error, etc., to achieve the effect of small depth error and wide sampling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

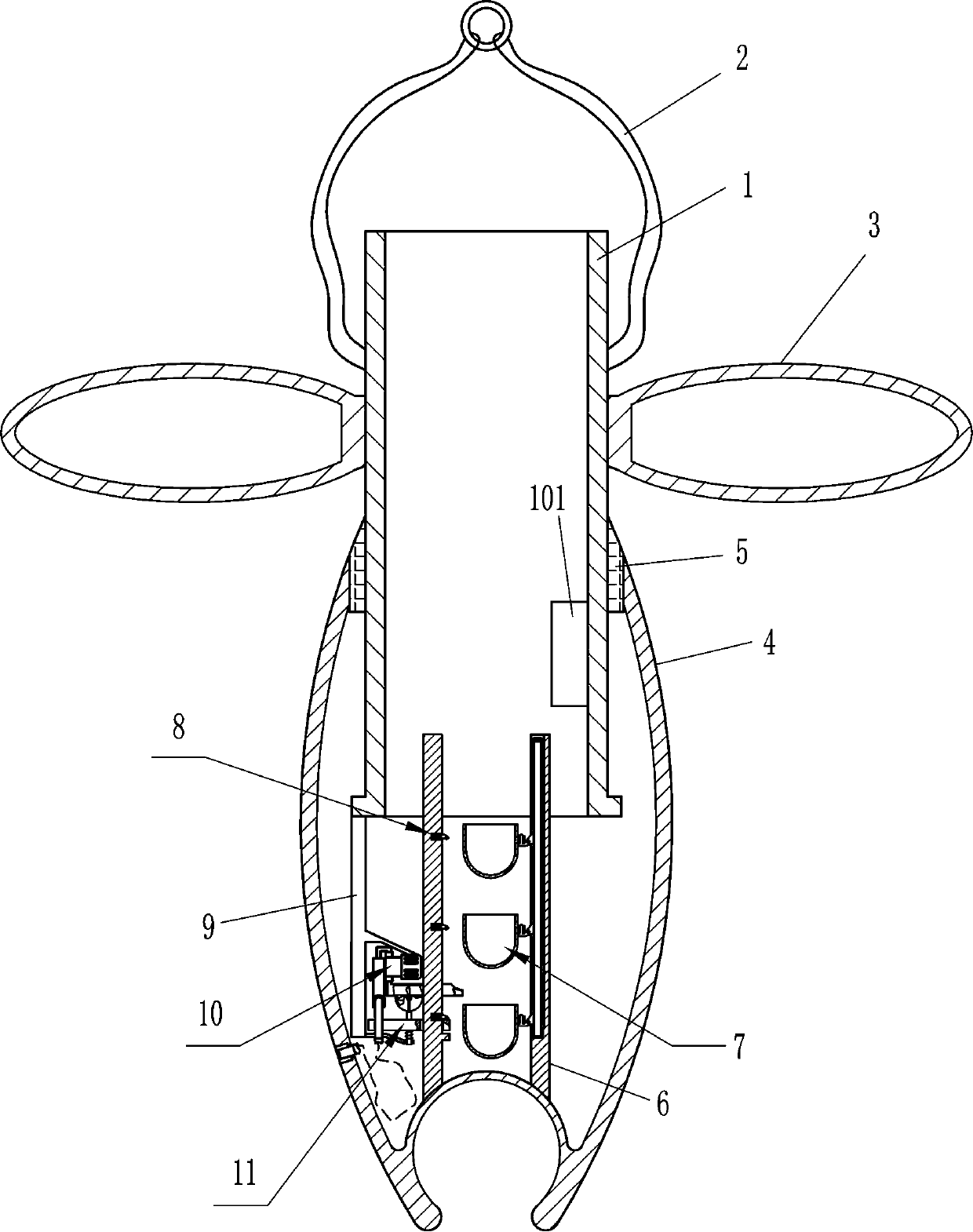

[0031] A kind of floating type water body detection automatic descending sampling equipment, such as Figure 1-3 As shown, it includes a pipe body 1, a sling 2, a floating body 3, a counterweight box 4, a seal 5, a mounting rod 6, a water collection device 7 for independently collecting water samples, a positioning mechanism 8, a mounting frame 9, and a power supply assembly 101. The pumping device 10 for taking water samples under control, the volume control device 11 for controlling the sampling volume, and the water outlet pipe 12; the pipe body 1 is used to install the internal parts of the equipment, the sling 2 is used for pulling, and the floating body 3 is used for the base The equipment provides buoyancy, the counterweight box 4 is used for controlled sinking, the seal 5 is used to prevent water seepage, the installation rod 6 is used to install the internal parts of the equipment, and the water collection device 7 is used to receive water and independently maintain wa...

Embodiment 2

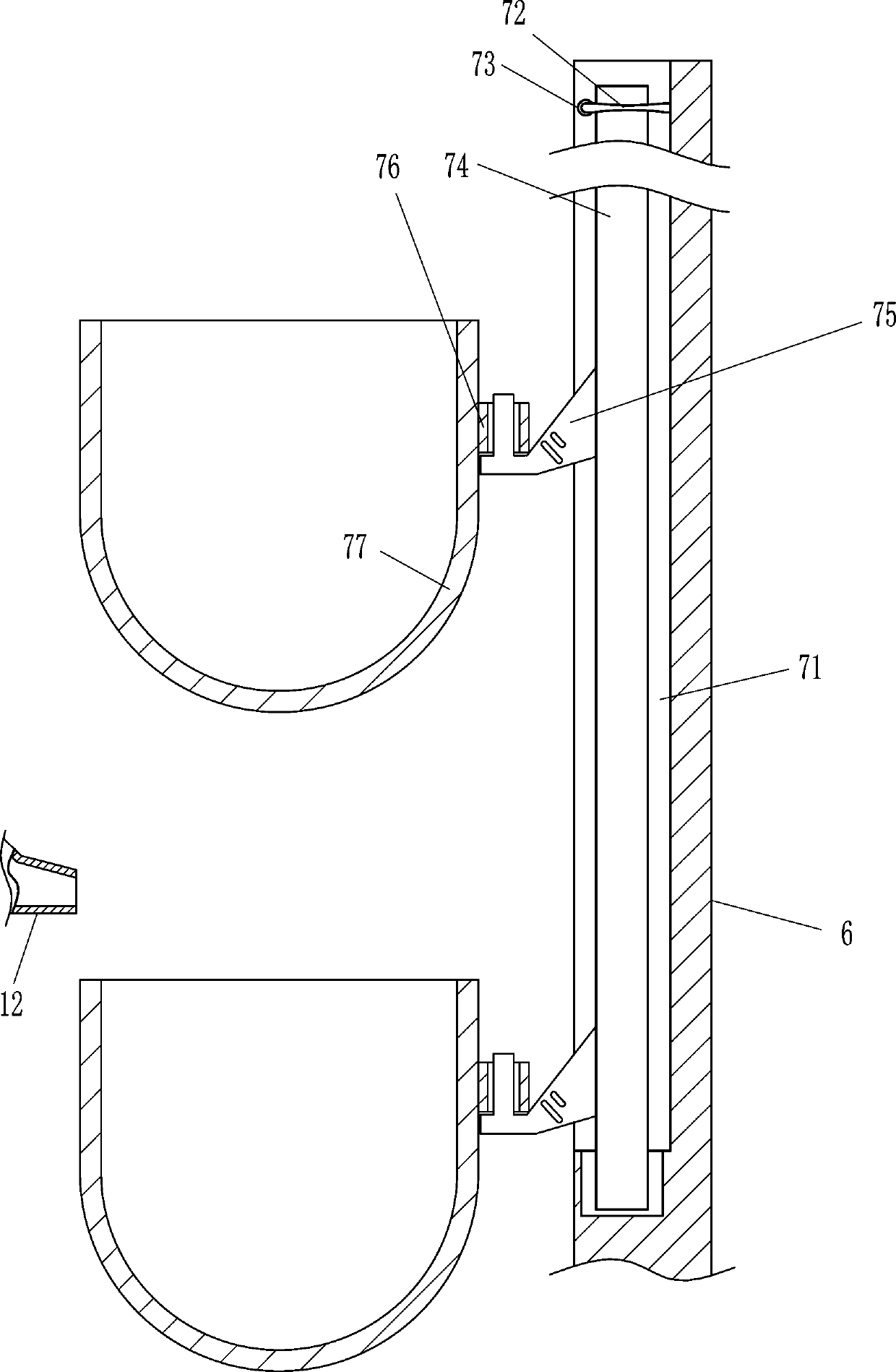

[0036] On the basis of Example 1, such as Figure 3-5 As shown, the water collecting device 7 includes a first elastic member 72, a block 73, a connecting rod 74, a placement frame 75, a placement sleeve 76 and a water collection box 77; specifically:

[0037] There is an installation groove 71 on the left side of the installation rod 6 on the right side, and two groups of first elastic members 72 are connected to the upper side of the inner wall of the installation rod 6 on the right side. block 73, a connecting rod 74 is placed in the installation groove 71, and the upper side of the connecting rod 74 is placed between two groups of the first elastic members 72 and two groups of the clamping blocks 73, and the left side of the connecting rod 74 Three groups of placement frames 75 are evenly distributed on the side, and the positions of the three groups of placement frames 75 correspond to the positioning mechanism 8. Placement sleeves 76 are placed on the placement frames 75...

Embodiment 3

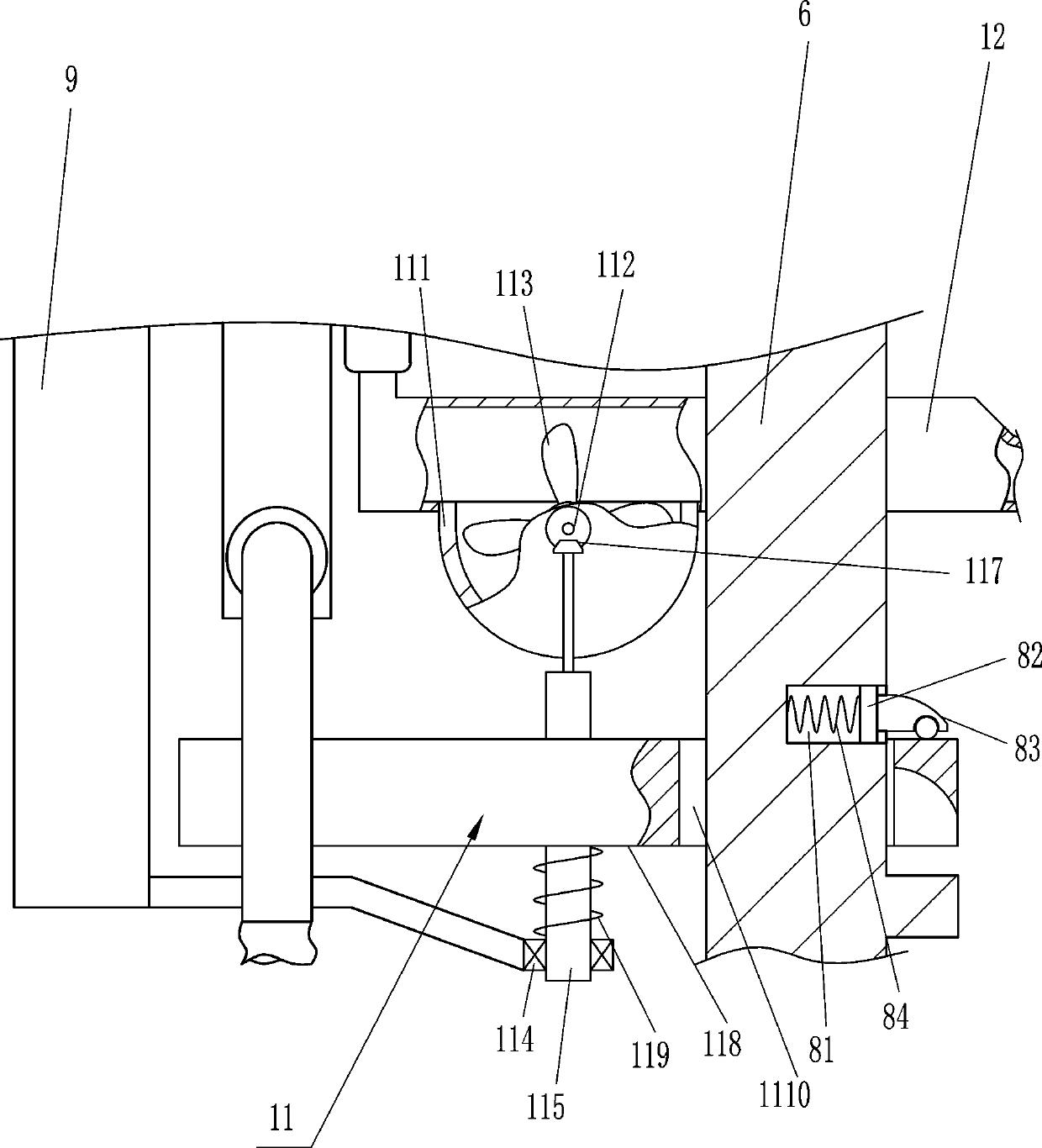

[0040] On the basis of Example 2, such as Figure 7-8 As shown, the positioning mechanism 8 includes a slider 82, a positioning block 83 and a second elastic member 84; specifically:

[0041] There are three slide grooves 81 on the right side of the mounting rod 6 on the left side, the positions of the slide grooves 81 correspond to the water collecting parts of the water collecting device 7, and the sliders 82 are slidably connected in the slide grooves 81. A positioning block 83 is connected to the right side of the slider 82 , and a second elastic member 84 is connected to the left side of the slider 82 .

[0042] When this embodiment is in operation, the amount control device 11 restricts the weight box 4 from moving down due to gravity by holding the positioning block 83, and by limiting the displacement of the weight box 4, the set will also be limited. Water device 7 moves down, if described positioning block 83 is not supported by described control device 11, then des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com