Portable soil sampler for construction

A technology for construction and soil fetching, applied in the direction of sampling devices, etc., can solve the problems of soil detection and detailed sampling, etc., and achieve the effect of being convenient for field detection and sampling, easy to expand, easy to carry and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

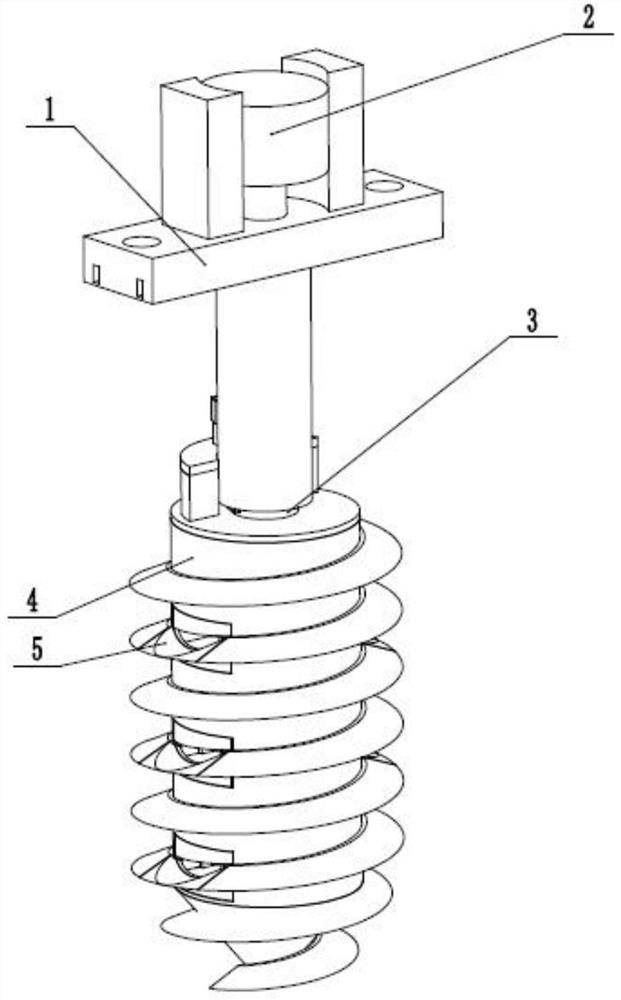

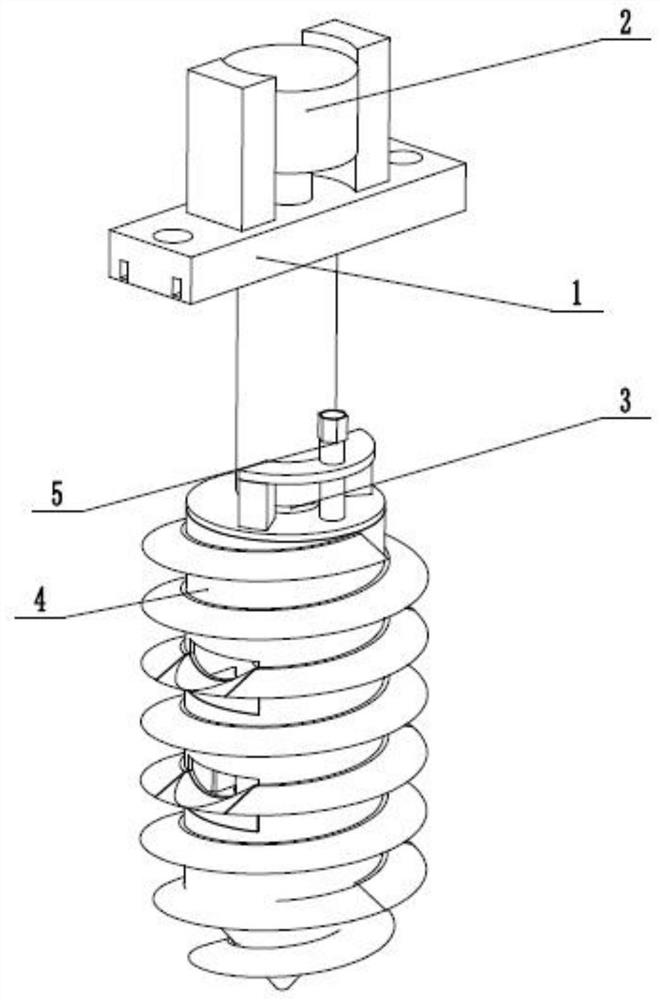

[0030] like Figure 1 to Figure 10 As shown, the portable soil fetcher for construction includes soil fetching holder 1, drilling driver 2, driving threaded sleeve 3, drilling threaded barrel 4 and layered soil sampler 5, and described drilling driver 2 is fixedly connected to On the soil-taking fixed seat 1, the inner end of the driving threaded sleeve 3 is longitudinally slidably connected in the hole-drilling driver 2, and the outer end of the driving threaded sleeve 3 is connected in the soil-taking fixed seat 1 through thread fit, and the driving threaded sleeve 3 is fixedly connected. On the threaded barrel 4 of the borehole, the layered soil sampler 5 is slidably connected in the threaded barrel 4 of the borehole. After selecting the designated location to be sampled, fix the soil-taking holder 1 through the insert plate and bolts, connect the hole-drilling driver 2 to the electric drive, and the hole-drilling driver 2 drives the threaded sleeve 3 to drive the drilling ...

specific Embodiment approach 2

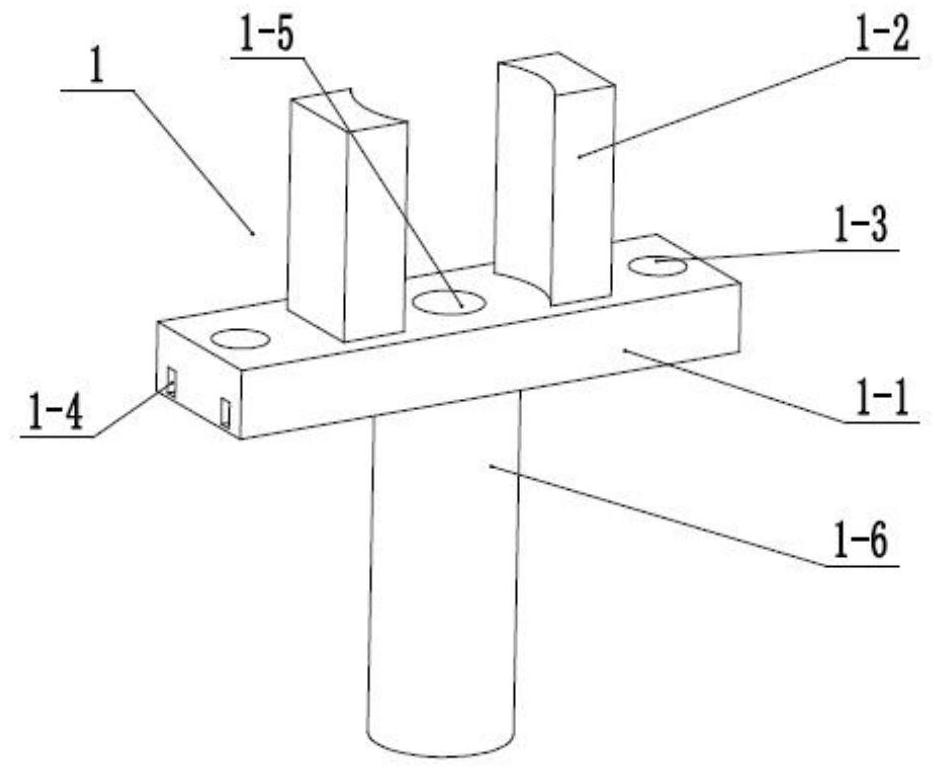

[0032] like Figure 1 to Figure 10As shown, this embodiment will further explain Embodiment 1. The soil-absorbing fixing base 1 includes a fixing platform 1-1, two motor fixing bases 1-2, two threaded fixing holes 1-3, and a horizontal fixing slot 1-4. Motor shaft rotation hole 1-5 and internal thread fixing sleeve 1-6, the upper end of fixing table 1-1 is fixedly connected with two motor fixing seats 1-2, and two threaded fixing holes 1-3 penetrate longitudinally respectively It is arranged on both sides of the fixed table 1-1, and both ends of the fixed table 1-1 are provided with a plurality of horizontal fixed slots 1-4, and the motor shaft rotation hole 1-5 is arranged at the middle end of the fixed table 1-1. The internal thread fixing sleeve 1-6 is fixedly connected to the center of the lower end of the fixing table 1-1. After selecting the specified position, fix the fixed table 1-1 by connecting the two threaded fixing holes 1-3 with bolts, or according to the actual...

specific Embodiment approach 3

[0034] like Figure 1 to Figure 10 As shown, this embodiment will further illustrate the second embodiment. The described hole driver 2 includes a drive motor 2-1, a drive extension shaft 2-2 and four longitudinal T-shaped chutes 2-3, and the drive motor 2- 1. It is fixedly connected between the two motor fixing seats 1-2. The transmission shaft of the driving motor 2-1 is rotatably connected in the circular hole 1-5 of the motor shaft. The upper end of the driving extension shaft 2-2 is connected to drive through a coupling The transmission shaft of the motor 2-1, four longitudinal T-shaped chutes 2-3 are evenly arranged on the drive extension rotating shaft 2-2. The drive motor 2-1 is powered forward and rotates, driving the extension rotating shaft 2-2 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com