Well drilling rod and pulse plasma drilling machine system

A technology for drilling rods and drilling rigs, which is applied in the field of plasma drilling rig systems, can solve the problems that the drill bit electrodes cannot be guaranteed to drill vertically, the drilling rig cannot work continuously, and cannot work normally, so as to improve energy utilization efficiency, simple structure, Reliable effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

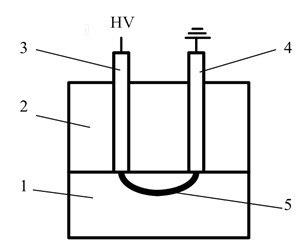

[0044] Combine the following figure 1 Explain the principle of pulsed plasma breaking rock. Such as figure 1 As shown, the rock 1 is placed in the deionized water 2, the high voltage electrode 3 and the ground electrode 4 are placed on the surface of the rock 1, and the high voltage electrode 3 and the ground electrode 4 are immersed in the deionized water environment. When a high-voltage pulse is applied between the high-voltage electrode 3 and the ground electrode 4, a discharge occurs between the high-voltage electrode 3 and the ground electrode 4, causing electrical breakdown of the rock 1, and forming a plasma channel 5 in the rock 1. Energy is injected into the plasma channel 5 and causes the plasma channel 5 to expand. The expansion of the channel will cause stress damage to the rock 1, and when the stress intensity of the rock 1 is exceeded, the rock 1 will be broken.

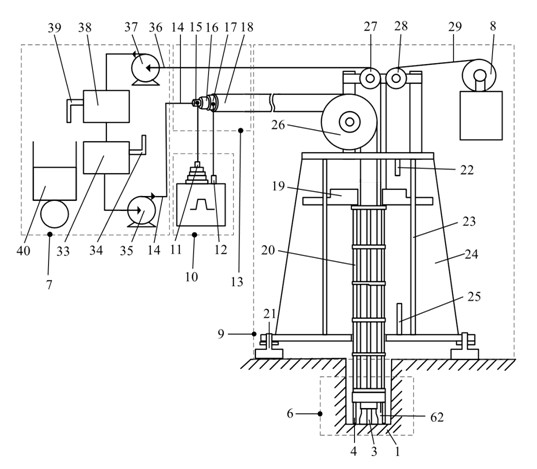

[0045] refer to figure 2 , The drilling rig system is mainly composed of a drilling mechanism 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com