Frameless sand pouring basin and manufacturing method thereof

A manufacturing method and sprue basin technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of unfavorable long-term production, high investment cost of sprue basin sand box, troublesome recycling, etc., and achieve simple production process Convenience, low cost, and the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

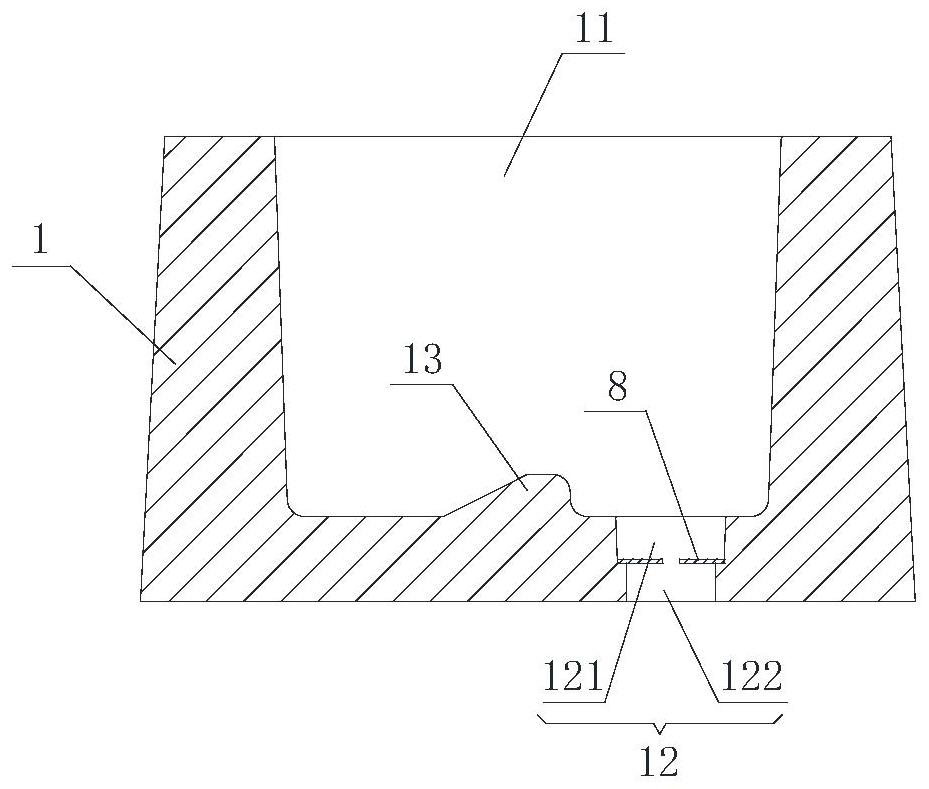

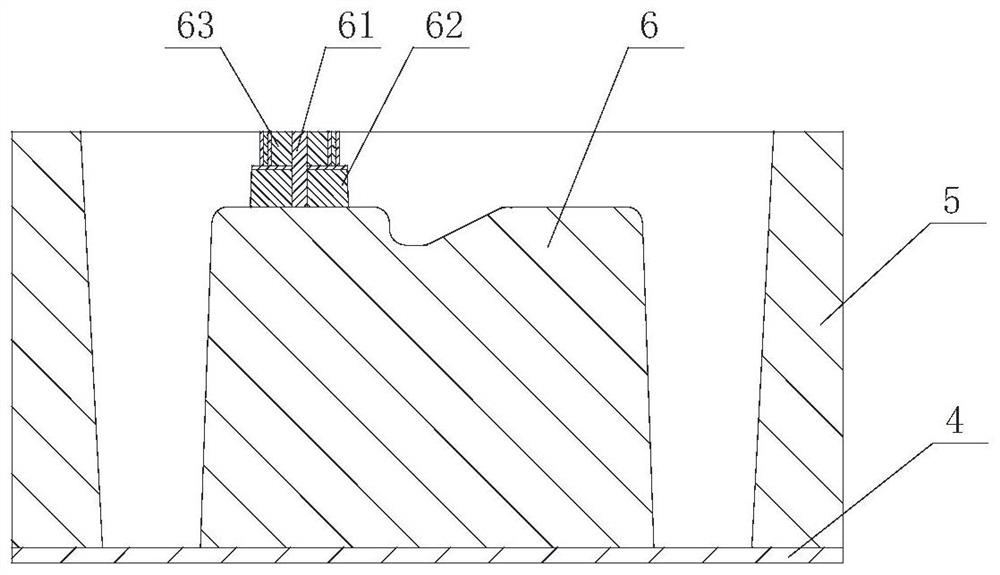

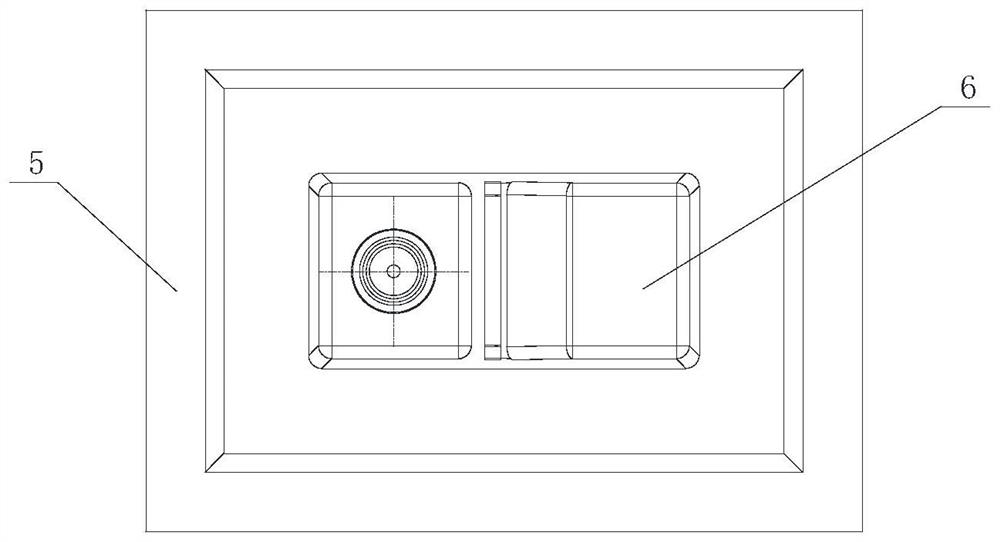

[0025] Such as figure 1 As shown, the frameless sand sprue basin of the present invention includes a sand mold main body 1, a pouring chamber 11 with an open top is provided in the middle of the sand mold main body 1, and a pouring channel 12 is provided at the bottom of the pouring chamber 11. The pouring chamber 11 The amount of sand eaten by the surrounding sand mold body 1 is not less than 130 mm, and a skeleton is provided in the sand mold body 1 on the side of the pouring cavity 11 . In the present invention, by designing a reasonable amount of sand to eat and matching the framework provided in the sand mold main body 1, the structural strength of the frameless sand sprue pot meets the requirements of use, and the sand sprue pot does not crack or crack during the hoisting and pouring process. problems such as deformation or collapse. Compared with the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com