High temperature resistant and compound salt resistant viscosity reduction agent for drilling fluid and preparation method thereof

A technology of high temperature resistance and compound salt, which is applied in the direction of drilling compositions, chemical instruments and methods, etc. It can solve the problems of high price, not very outstanding high temperature resistance, limited high temperature resistance or salt resistance, and calcium resistance. , to achieve the effects of low cost, remarkable wellbore stability and outstanding calcium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

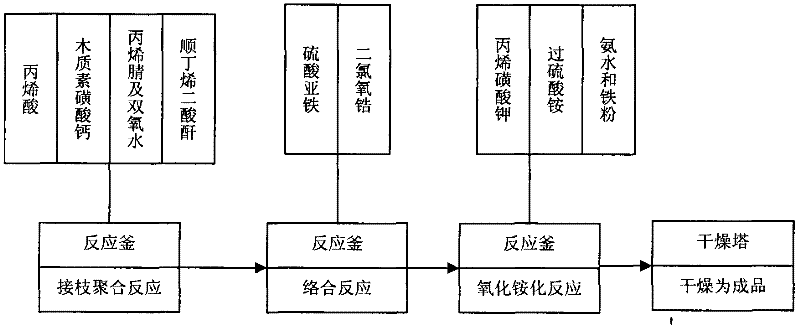

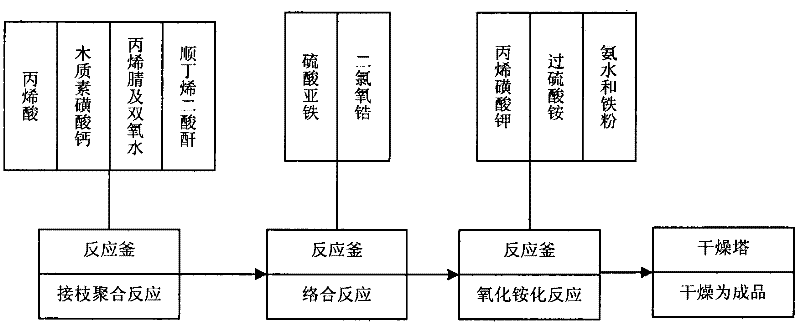

Method used

Image

Examples

Embodiment 1

[0030] Prepare materials according to the ratio (mass ratio) of deionized water:acrylic acid:acrylonitrile:maleic anhydride:calcium lignosulfonate:hydrogen peroxide=100:30:10:15:20:10.

[0031] a. Graft polymerization reaction

[0032] For example, add 1000kg of deionized water into a 3000L enamel reaction kettle, start stirring, slowly add 300kg of acrylic acid, 150kg of maleic anhydride, 100kg of acrylonitrile and 200kg of calcium lignosulfonate, raise the temperature to 55°C, and slowly Add 100kg of hydrogen peroxide, control the adding speed, keep boiling slightly, stir and react for about 1 hour, and a yellow liquid is formed.

[0033] Note: Controlling the reaction temperature in this step is the key. If the reaction is too violent, the drop rate of hydrogen peroxide should be slowed down.

[0034] b. Complexation reaction

[0035] Cool the reaction solution to about 50°C, add 92.5kg of ferrous sulfate and 55.5kg of zirconium oxychloride to the reaction kettle under st...

Embodiment 2

[0040] Prepare materials according to the ratio (mass ratio) of deionized water:acrylic acid:acrylonitrile:maleic anhydride:calcium lignosulfonate:hydrogen peroxide=100:40:20:20:30:25.

[0041] a. Graft polymerization reaction

[0042] For example, add 1000kg of deionized water into a 5000L enamel reaction kettle, start stirring, slowly add 400kg of acrylic acid, 200kg of maleic anhydride, 200kg of acrylonitrile and 300kg of calcium lignosulfonate, raise the temperature to 60°C, and slowly Add 250kg of hydrogen peroxide, control the adding speed, keep boiling slightly, stir and react for about 1 hour, and a yellow liquid is formed.

[0043] Note: Controlling the reaction temperature in this step is the key. If the reaction is too violent, the drop rate of hydrogen peroxide should be slowed down.

[0044] b. Complexation reaction

[0045] Cool the reaction liquid to about 50°C, add 188kg of ferrous sulfate and 141kg of zirconium oxychloride to the reaction kettle, and use fer...

Embodiment 3

[0050] Prepare materials according to the ratio (mass ratio) of deionized water:acrylic acid:acrylonitrile:maleic anhydride:calcium lignosulfonate:hydrogen peroxide=100:35:15:18:25:20.

[0051] a. Graft polymerization reaction

[0052] For example, add 1000kg of deionized water into a 3000L enamel reaction kettle, start stirring, slowly add 350kg of acrylic acid, 180kg of maleic anhydride, 150kg of acrylonitrile and 250kg of calcium lignosulfonate, raise the temperature to 60°C, and slowly Add 200kg of hydrogen peroxide, control the adding speed, keep boiling slightly, stir and react for about 1 hour, and a yellow liquid is formed.

[0053] Note: Controlling the reaction temperature in this step is the key. If the reaction is too violent, the drop rate of hydrogen peroxide should be slowed down.

[0054] b. Complexation reaction

[0055] Cool the reaction solution to about 50°C, add 150kg of ferrous sulfate and 115kg of zirconium oxychloride to the reaction kettle, and use f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com