Dry-hole pressure relief valve and hydraulic fracturing crustal stress testing device

The technology of a test device and a pressure relief valve is applied in the direction of a measuring device, a force/torque/work measuring instrument, a force sensor in a hole of a force-bearing structure, etc., which can solve problems such as the complexity of the test equipment, and achieve simple structure and high test efficiency. Stable, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

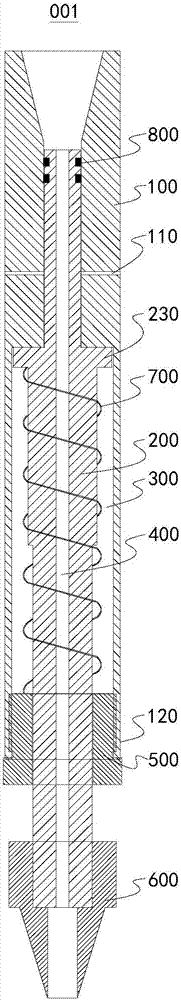

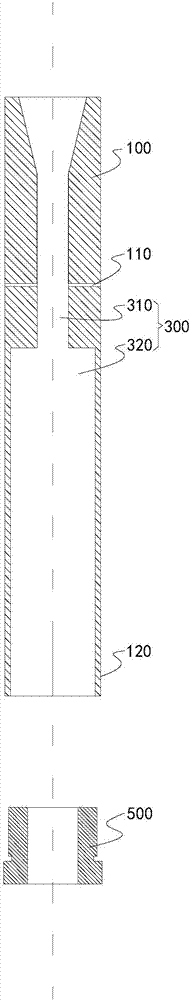

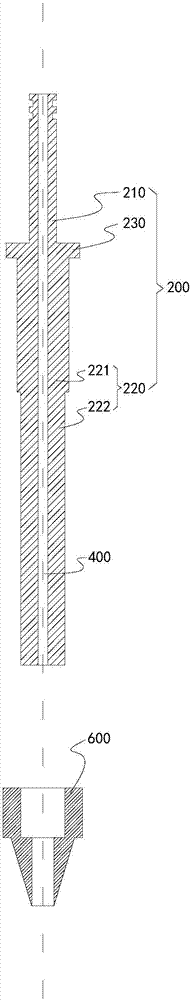

[0034] Please refer to Figure 1 to Figure 3 As shown, this embodiment provides a dry hole pressure relief valve 001, which includes a valve body 100 and a valve core 200. The valve body 100 has a valve cavity 300 that is arranged along its axis and is penetrated. The valve core 200 has a valve body that is arranged along its axis. The valve core 200 is inserted into the valve cavity 300 by the insertion end 120 of the valve body 100, and one end extends from the insertion end 120. There is a gap between the valve core 200 and the valve body 100, and the valve body 100 is far away from the insertion end. One end of 120 communicates with one end of the valve core 200 through the valve cavity 300, and then communicates with the end of the valve core 200 protruding from the insertion end 120 through the through hole 400 to realize the communication between the two ends of the dry hole pressure relief valve 001. The valve 001 is installed on the drill pipe, and the packer capsule c...

no. 2 example

[0041] Please refer to Figure 4 As shown, this embodiment provides a hydraulic fracturing in-situ stress testing device 002, which includes a collector 023, a high-pressure pump 010, a switching valve 020, and an elevator 017, which is suspended below the elevator 017 and inserted downward into the borehole The drill rod 018 in the borehole 019 and the packer 021 in the borehole 019. The high-pressure pump 010 communicates with the top end of the borehole 019. The bottom end of the borehole 019 is connected to the dry hole pressure relief valve 001 in the first embodiment. The top end is connected, the bottom end of the dry hole pressure relief valve 001 is connected to the top end of the switching valve 020, and the bottom end of the switching valve 020 is connected to the packer 021.

[0042] In this embodiment, the dry hole pressure relief valve 001 is arranged vertically, the top end of the dry hole pressure relief valve 001 is the end far from the insertion end 120, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com