Technique for treating sewage of high well and deep drilling well

A technology for treating process and sewage, which is applied in the field of high well depth drilling sewage treatment process, can solve the problem that coagulation cannot be effectively treated, and achieve the effect of reducing impact and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

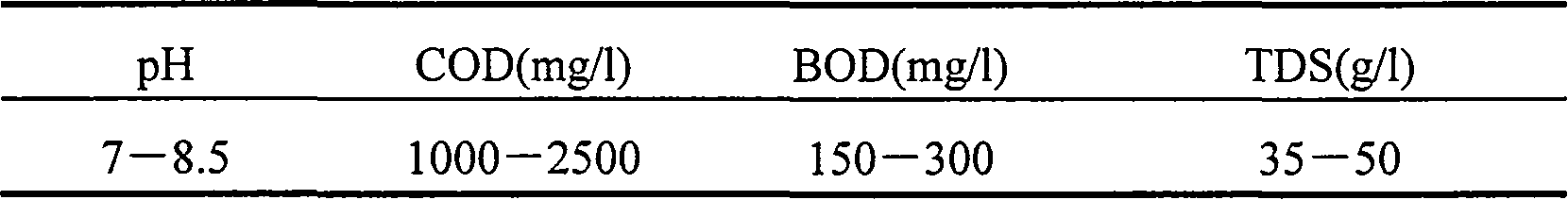

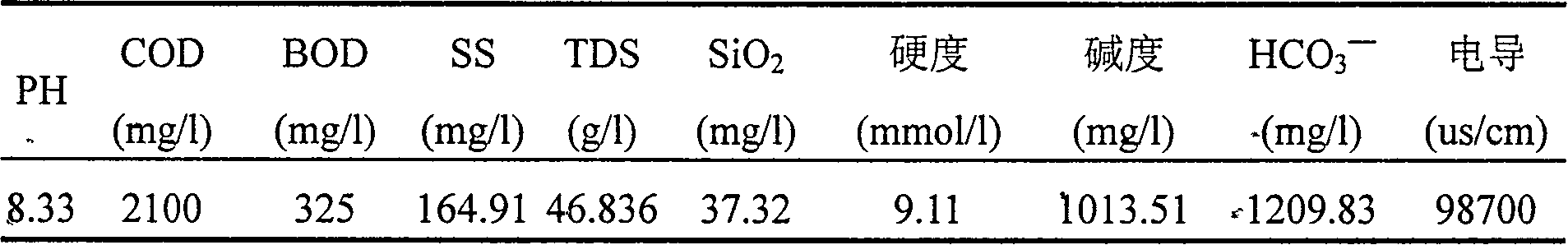

[0036] Take the 2,500-meter-deep drilling sewage of a well mine, and the water quality of this sewage is shown in Table 2.

[0037] Table 2. The water quality of drilling sewage in a well mine

[0038]

[0039] First, add 10g / L calcium hydroxide to the sewage, and react for 30 minutes to form chemical precipitation with the sulfonic acid in the sewage; adopt the air flotation method, the hydraulic retention time is 20min, and carry out solid-liquid separation; after solid-liquid separation, the water is discharged Adjust the pH to 6-9, then add 400mg / l polyaluminum to react for 30min, carry out coagulation and demulsification, add 2ppm polyacrylamide for 30min precipitation and separation; after the coagulation process, adjust the pH of the effluent to 3.5 for ultrasonication Fenton oxidation (H 2 o 2 : 1500mg / l, Fe 2+ : 5mmol / L) After 4 hours, the pH was adjusted to neutral for solid-liquid separation; the effluent was oxidized by Fenton and carried out in the aerated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com