Side milling processing method of resembled ruled surface integral wheel curved surfaces

A technology of integral impeller and processing method, which is applied in the direction of metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problem that the side milling processing method is only applicable, and achieve the effect of simple implementation, high calculation efficiency, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

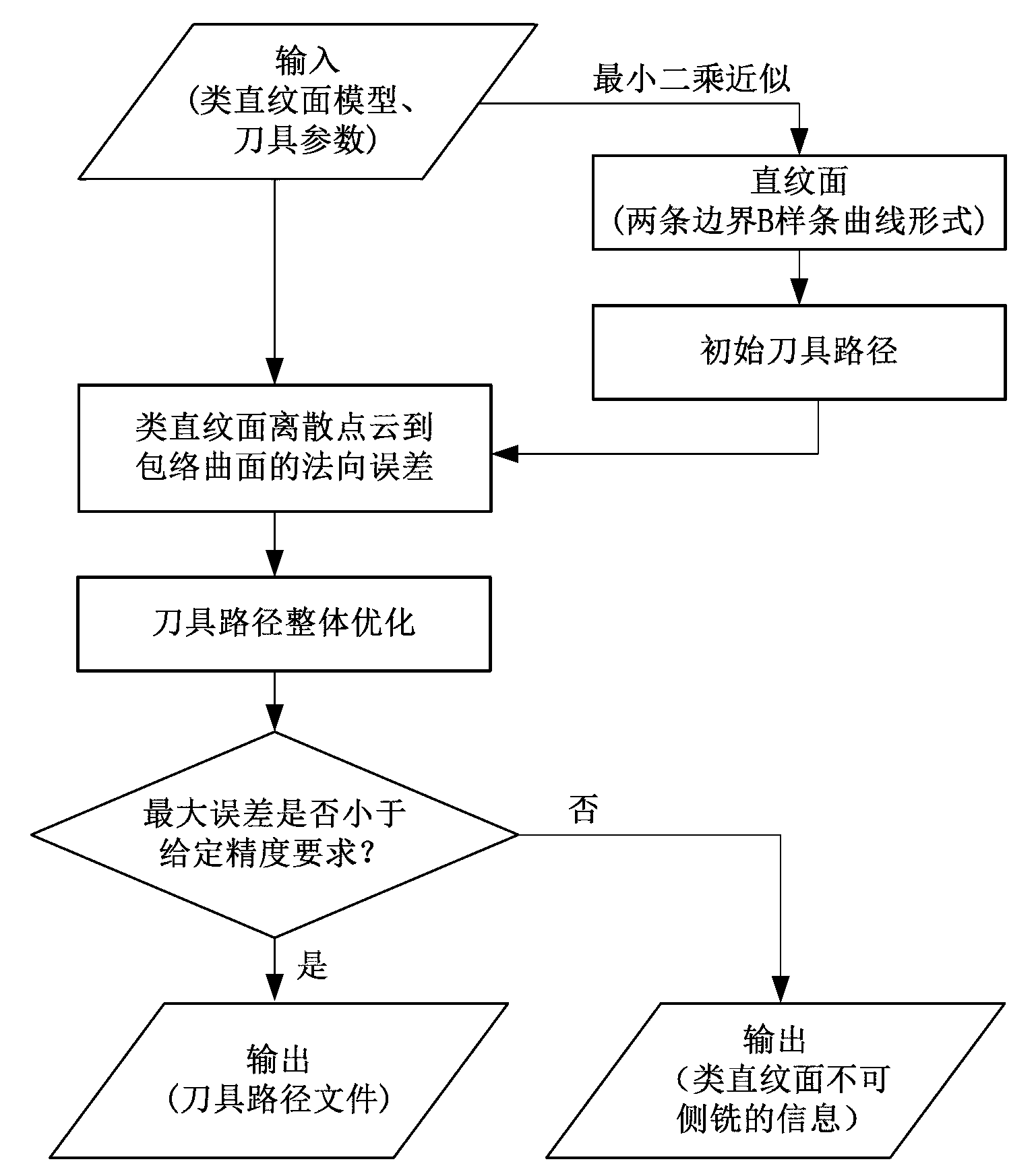

[0039] see figure 1 , a side milling method for a ruled-like integral impeller surface, comprising the following steps:

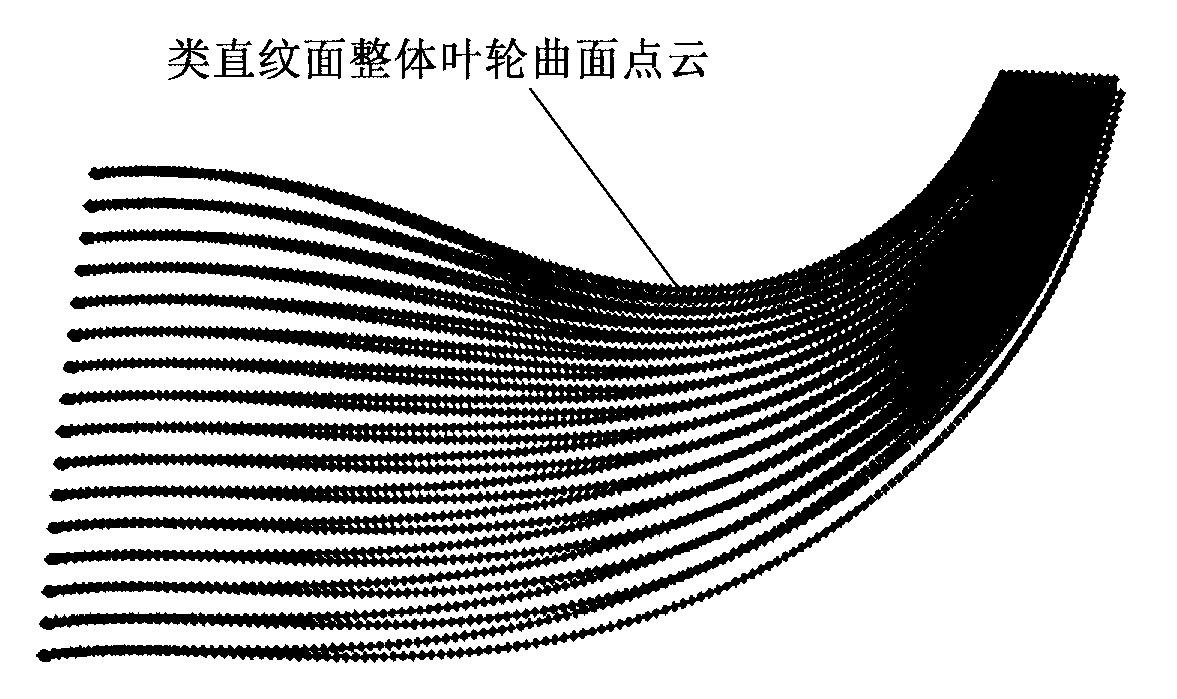

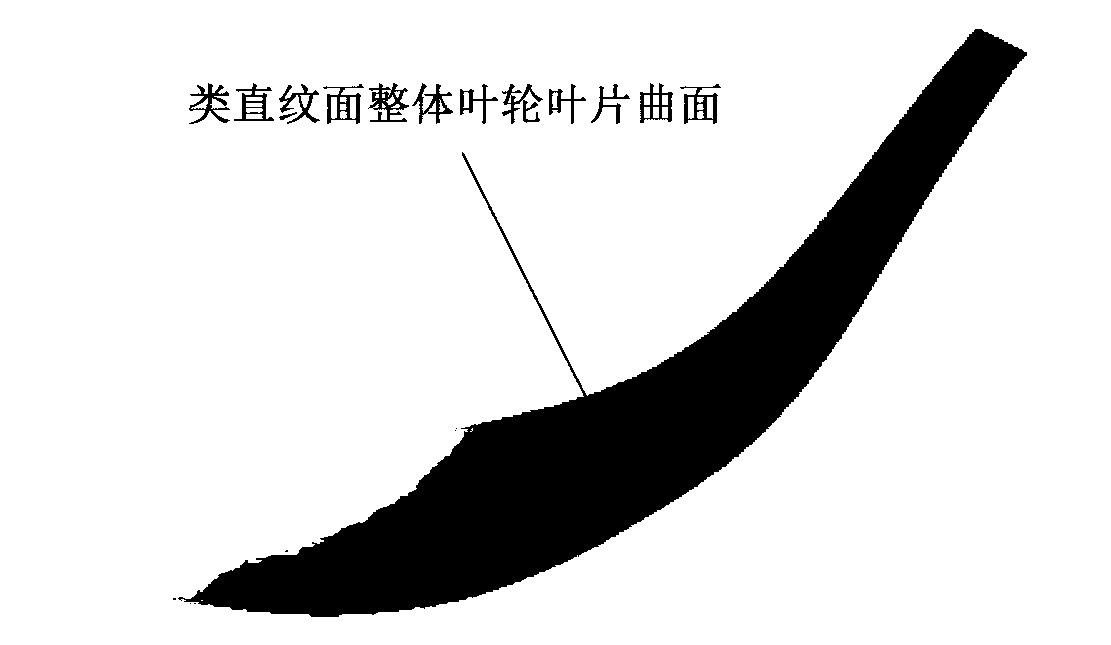

[0040] (1) According to the ruled surface overall impeller surface, the approximate ruled surface is obtained based on the principle of least squares, and the approximate ruled surface is represented by two boundary cubic B-spline curves.

[0041] The quasi-ruled surface can be a three-dimensional surface model or a surface point cloud data file, and two boundary cubic B-spline curves approach the discrete point cloud of the quasi-ruled surface in the sense of least squares.

[0042] (2) According to the obtained approximate ruled surface and the given tool parameters, the discrete tool position and attitude are obtained by the offset method, and the initial tool path is obtained by B-spline curve interpolation.

[0043] Tool parameters are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com