Sintering method for ultrafine hard alloy

A technology of cemented carbide and sintering method, applied in the field of alloys, can solve problems such as insufficient grain development, and achieve the effects of excellent comprehensive mechanical properties, improved fracture toughness, improved performance stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

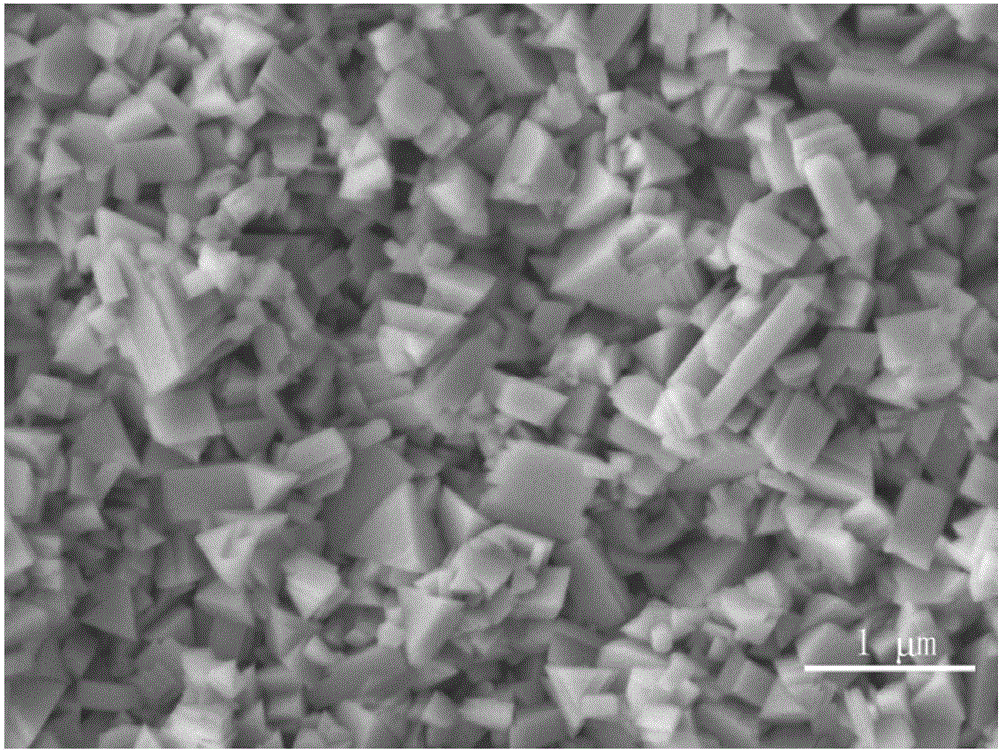

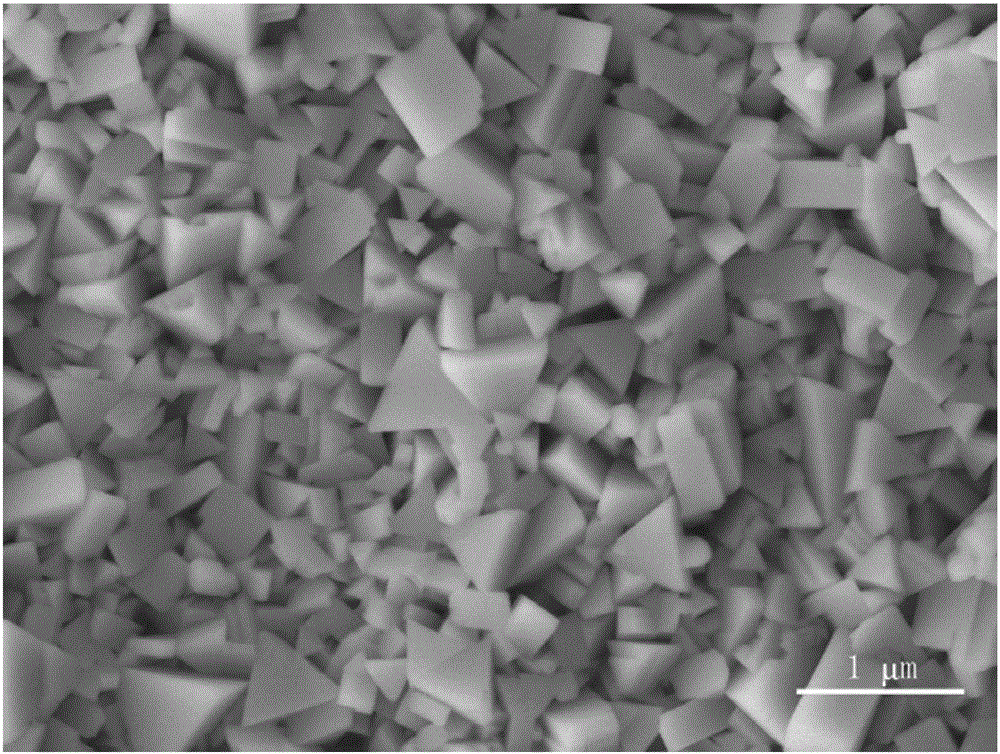

Image

Examples

Embodiment 1

[0032] Example 1: The grain size is 0.4 μm, the binder phase is pure cobalt, the mass percentage is 6.5%, the inhibitor is 0.3% VC and 0.4% Cr 2 C 3 Two-step sintering process of cemented carbide compacts.

[0033] WC powder, Co powder, molding agent (paraffin or PEG) and inhibitor are mixed, ball milled, and molded to prepare a compact; the compact is loaded into a pressure sintering furnace, and the 5 Pa hydrogen atmosphere and 380°C dewaxing for 180min; use 15°C / min heating rate, quickly raise the temperature to 1470°C under vacuum condition, keep it for 15min, then use 10°C / min cooling rate to cool down to 1400°C, charge Inject argon to a pressure of 80×10 5 Pa, heat preservation and sintering for 90 minutes, then power off and cool to room temperature with the furnace to obtain ultrafine cemented carbide.

[0034] The performance of the WC (0.4 μm)-6.5wt.% Co product prepared by the two-step sintering method is shown in Table 1, and compared with the one-step sintering...

Embodiment 2

[0038] Example 2: The grain size is 0.4 μm, the binder phase is pure cobalt, the mass percentage is 7%, the inhibitor is 0.3% VC and 0.4% Cr 2 C 3 Two-step sintering process of cemented carbide compacts.

[0039] WC powder, Co powder, molding agent (paraffin or PEG) and inhibitor are mixed, ball milled, and prepared into a compact by extrusion; the compact is loaded into a pressure sintering furnace, and the 5 Pa hydrogen atmosphere and 380°C dewaxing for 180min; use 18°C / min heating rate, quickly heat up to 1480°C under vacuum conditions, keep warm for 12min and then use 12°C / min cooling rate to cool down to 1400°C, fill in Argon to a pressure of 70 x 10 5 Pa, heat preservation and sintering for 80 minutes, then power off and cool to room temperature with the furnace to obtain ultrafine cemented carbide.

[0040] The performance of the WC (0.4 μm)-7wt.% Co product prepared by the two-step sintering method is shown in Table 2, and compared with the one-step sintering (1400°...

Embodiment 3

[0044] Example 3: The grain size is 0.4 μm, the binder phase is pure cobalt, the mass percentage is 8%, the inhibitor is 0.3% VC and 0.4% Cr 2 C 3 Two-step sintering process of cemented carbide compacts.

[0045] WC powder, Co powder, molding agent (paraffin or PEG) and inhibitor are mixed, ball milled, and molded to prepare a compact; the compact is loaded into a pressure sintering furnace, and the 5 Pa hydrogen atmosphere and 380°C dewaxing for 180min; use 20°C / min heating rate, quickly raise the temperature to 1490°C under vacuum conditions, keep warm for 10min and then use 15°C / min cooling rate to cool to 1400°C, fill in Argon to a pressure of 60 x 10 5 Pa, heat preservation and sintering for 60 minutes, then power off and cool to room temperature with the furnace to obtain ultrafine cemented carbide.

[0046] The performance of the WC (0.4 μm)-8wt.% Co product prepared by the two-step sintering method is shown in Table 3, and compared with the one-step sintering (1400 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com