Water jet cutter dicing machine device

A granulator and water jet cutting technology, applied in the field of rubber and plastic extrusion granulation, to achieve the effect of simple operation, excellent performance and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

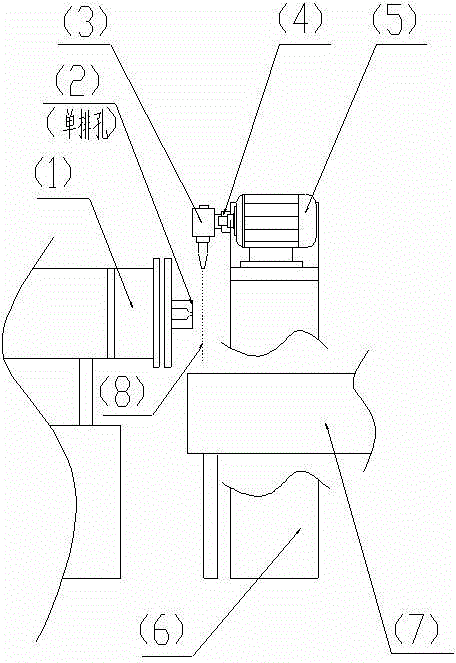

[0041] according to figure 1 , figure 2 , Image 6 As shown, the water knife pelletizer device of the present invention is installed, before the extruder reaches the discharge index required by the process, the high-pressure water pump 12 is opened earlier, the water pressure reaches more than 15Mpa, the outlet valve of the high-pressure water pump 12 is opened, and the cutting head is observed. In the case of the water line (water arrow) 8 of the injection, adjust the gap between the water line (water arrow) 8 and the discharge die of the extruder to about 1mm, and temporarily manually adjust the speed of the frequency conversion speed regulating motor 5 at 500 / min. Start the extruder to discharge the material, and then adjust the rotating speed of the frequency conversion speed regulating motor 5 according to the pelletizing situation, so that the shape of the product can meet the requirements of product quality. Tap water needs to enter the high-pressure water pump throug...

Embodiment 2

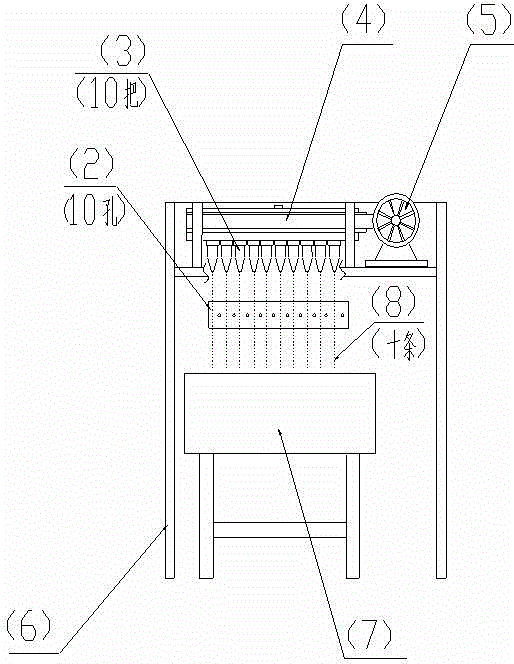

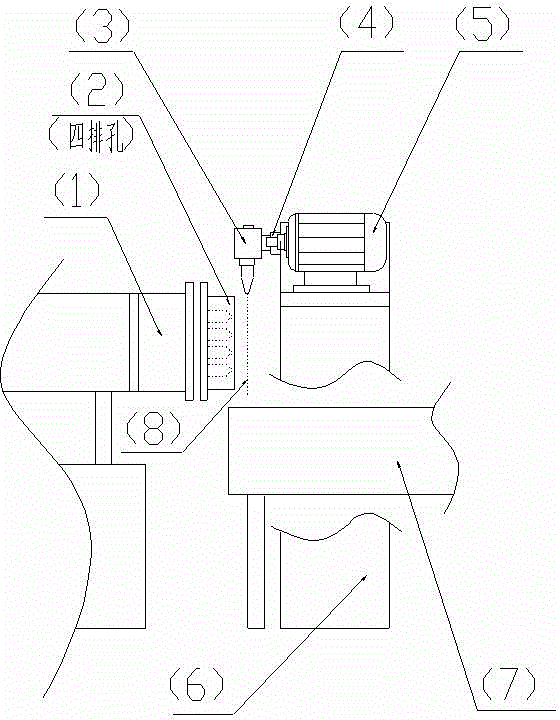

[0043] according to image 3 , Figure 4 , Image 6 As shown, installing the water jet granulator device of the present invention makes the work efficiency of the present invention improve more than several times, image 3 , Figure 4 Four rows of four cutting heads shown illustrate the expandable space of the present invention, which can be used to match the excellent performance of extruders with different production capacities. Before the extruder reaches the discharge index required by the process, first turn on the high-pressure water pump 12, the water pressure reaches above 15Mpa, open the outlet valve of the high-pressure water pump 12, observe the situation of the water line (water arrow) 8 shot out by the cutting head, and adjust The gap between the water line (water arrow) 8 and the discharge die of the extruder is about 1mm. For the time being, first manually adjust the speed of the frequency conversion speed regulation motor 5 at 500 / min, and then start the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com