Method for machining normal straight profile cylindrical worm by using horizontal lathe

A horizontal lathe and worm technology, applied in the direction of worms, toothed components, belts/chains/gears, etc., can solve the problem that the normal straight profile cylindrical worm cannot be processed, shorten the production cycle and improve the ability , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

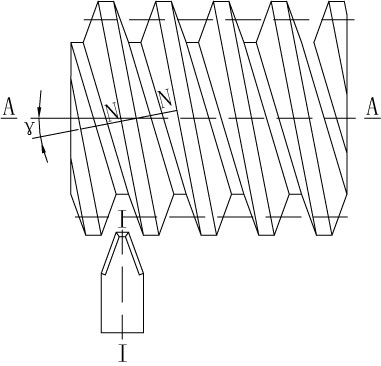

[0010] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this implementation mode, this implementation mode is realized through the following steps:

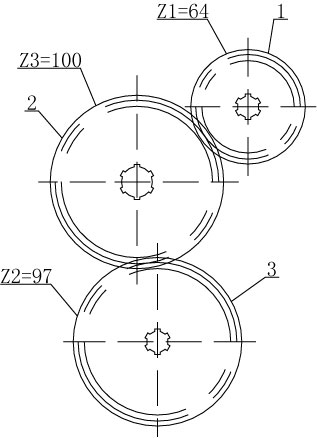

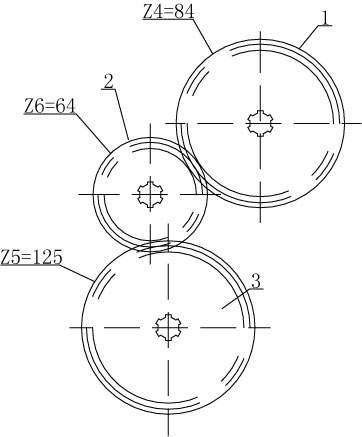

[0011] Step 1. Change the number of teeth of the gear set in the wheel box of the horizontal lathe to change the pitch: the axial pitch of the horizontal lathe is not equal to the axial pitch of the normal straight-profile cylindrical worm. In order to make the axial pitch of the horizontal lathe It is equal to the axial pitch of the normal straight-profile cylindrical worm. First, the number of teeth of the gear set in the hanging wheel box of the horizontal lathe should be changed to change the transmission ratio i of the hanging wheel box. There are three straight teeth in the hanging wheel box of the horizontal lathe Cylindrical gears are driving wheel 1, driven wheel 2 and intermediate wheel 3. Before the change, the parameters of each gear are: the number of teeth of the driving wheel 1 is Z1, the n...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, the rotating knife rod 4 in step 2 of this embodiment is provided with a rotation scale 4-1. Make the cutter head reach the accurate metering scale value when rotating. Other steps are the same as in the first embodiment.

[0015] Application example of the present invention: C620 horizontal lathe is now used to process normal straight profile cylindrical worm, C620 lathe axial pitch P1=9.42, modulus m=3, the parameters of the gear set in the hanging wheel box are shown in Table 1:

[0016] Table 1:

[0017]

Drive wheel Z1

Driven wheel Z2

Intermediate wheel Z3

Modulus m

1.75

1.75

1.75

Number of teeth Z

64

97

100

20°

20°

20°

Bore spline

φ28+0.02×φ23×6

φ28+0.02×φ23×6

φ38+0.02×φ33×6

Gear width

40-0.2

40-0.2

40-0.2

[0018] The axial pitch of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com