Method for machining normal straight profile cylindrical worm by using horizontal lathe

A horizontal lathe, worm technology, applied in the worm, toothed components, belts/chains/gears, etc., can solve the problem that the normal straight profile cylindrical worm cannot be machined, shorten the production cycle, get rid of control and The effect of restricting and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

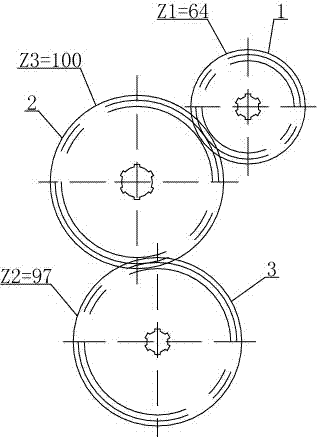

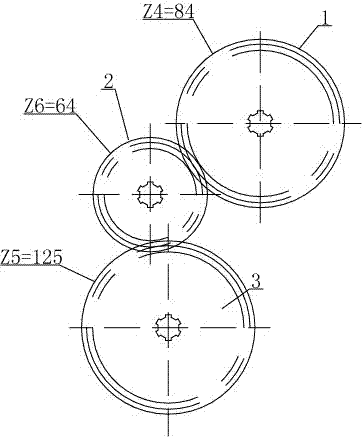

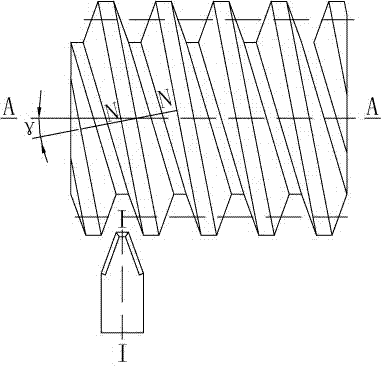

[0010] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this implementation mode, this implementation mode is realized through the following steps:

[0011] Step 1. Change the number of teeth of the gear set in the wheel box of the horizontal lathe to change the pitch: the axial pitch of the horizontal lathe is not equal to the axial pitch of the normal straight-profile cylindrical worm. In order to make the axial pitch of the horizontal lathe It is equal to the axial pitch of the normal straight-profile cylindrical worm. First, the number of teeth of the gear set in the hanging wheel box of the horizontal lathe should be changed to change the transmission ratio i of the hanging wheel box. There are three straight teeth in the hanging wheel box of the horizontal lathe Cylindrical gears are driving wheel 1, driven wheel 2 and intermediate wheel 3. Before the change, the parameters of each gear are: the number of teeth of the driving wheel 1 is Z1, the n...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 with figure 2 To describe this embodiment, the rotating knife rod 4 in step 2 of this embodiment is provided with a rotation scale 4-1. Make the cutter head reach the accurate metering scale value when rotating. Other steps are the same as in the first embodiment.

[0015] Application example of the present invention: C620 horizontal lathe is now used to process normal straight profile cylindrical worm, C620 lathe axial pitch P1=9.42, modulus m=3, the parameters of the gear set in the hanging wheel box are shown in Table 1:

[0016] Table 1:

[0017] Drive wheel Z1 Driven wheel Z2 Intermediate wheel Z3 Modulus m 1.75 1.75 1.75 Number of teeth Z 64 97 100 pressure angle α 20° 20° 20° Bore spline φ28+0.02×φ23×6 φ28+0.02×φ23×6 φ38+0.02×φ33×6 Gear width 40-0.2 40-0.2 40-0.2

[0018] The axial pitch of the normal straight profile cylindrical worm to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com