Automatic sugar coiling machine

A sugar machine and automatic technology, applied in confectionery, confectionary industry, food science, etc., can solve the problems of prolonging the cooling time of candy bars, low production efficiency, unfavorable candy bar coiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

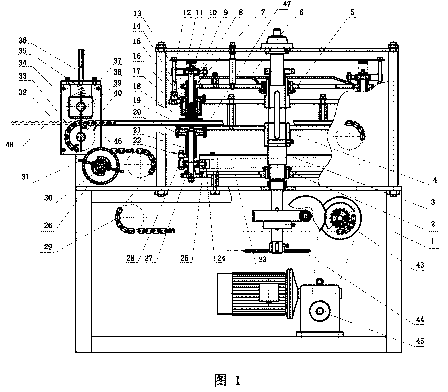

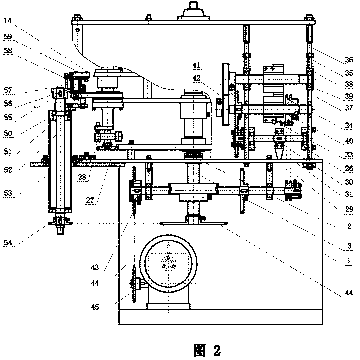

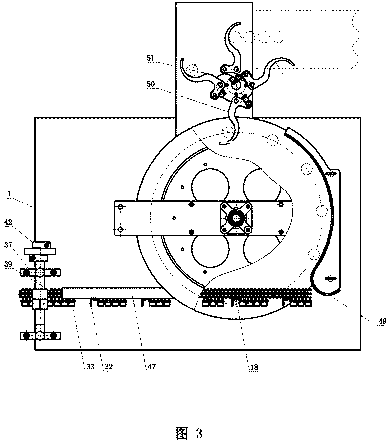

[0021] exist figure 1 , figure 2 and image 3In the automatic sugar winding machine shown, the main shaft 3 is vertically arranged on the frame 1 through the bearing, and the central turntable 4 is fixedly installed on the main shaft 3. The central turntable 4 is composed of two upper disks and a lower disk arranged at intervals. , a plurality of perforations are evenly distributed on the surface of the central turntable 4, and the number of perforation holes set in this embodiment is 12. The outer seat 14 of the gear sleeve is fixedly connected in the perforation of the upper disc, and the outer seat 14 of the gear sleeve is connected with the winding device 7 through the bearing rotation, and the winding device 7 passes through the winding gear sleeve 13 contained therein. Engaged with the sugar-wound sun wheel turntable 5, the sugar-wound sun wheel turntable 5 is slidingly sleeved on the journal above the center turntable 4, and is fixedly connected with the frame 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com